Extrusion components for metal plastic extrusion forging

A component and plastic technology, applied in metal extrusion forming tools, metal extrusion control equipment, metal extrusion, etc., can solve the problem of affecting the internal structural performance of forming workpieces, increasing equipment costs and energy consumption, and reducing the quality of forming workpieces and other issues, to achieve the effect of improving the internal structural performance, reducing the difficulty, and reducing the difficulty of extrusion and forging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

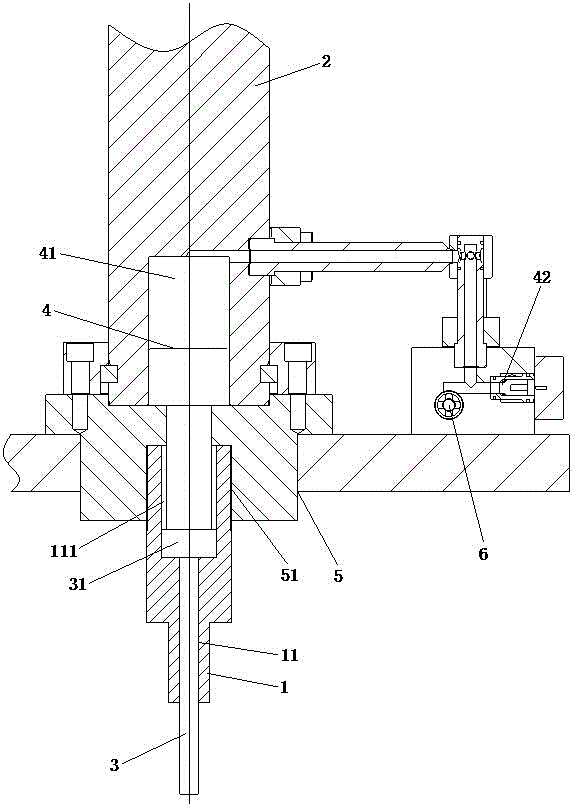

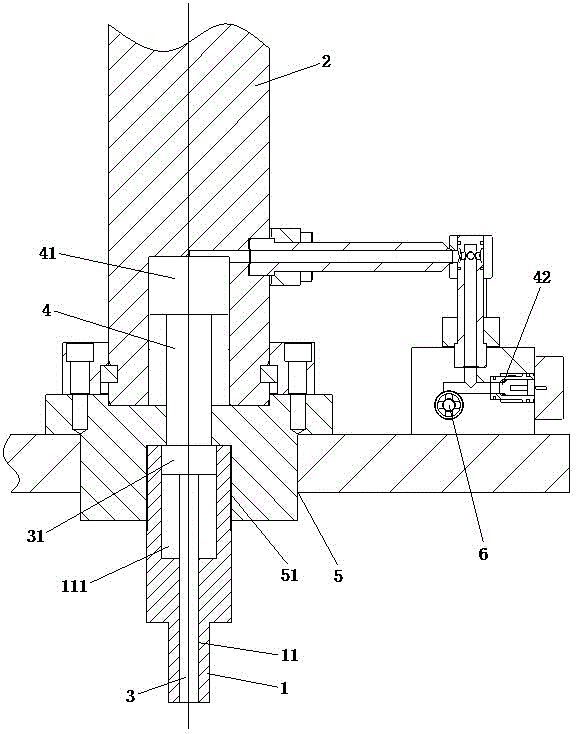

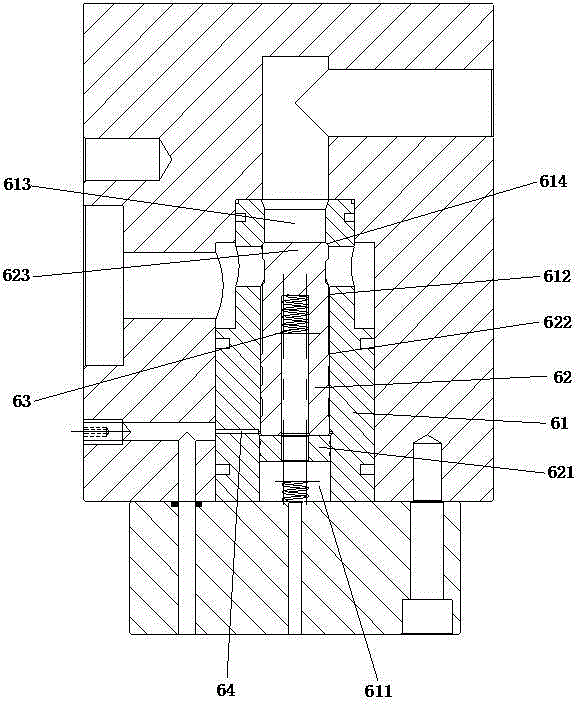

[0025] like figure 1 and figure 2 As shown, the extrusion forging assembly used for metal plastic extrusion forging in the present invention includes an extrusion forging head 1 and an extrusion forging driving mechanism 2 for driving the extrusion forging head 1 to extrude the blank, and is also provided with a device for extruding holes on the blank The extrusion head 3 and the extrusion driving mechanism 4 connected with the extrusion head 3, the extrusion head 3 is slidably installed in the extrusion forging head 1 along the extrusion forging direction, the extrusion driving mechanism 4 can drive the extrusion head 3 to extend out for extrusion The head 1 squeezes a hole on the blank, and after the hole is squeezed out, the hole extrusion head 3 is retracted into the extrusion forging head 1 and the blank is jointly extruded wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com