Horizontal rotary-mold extrusion forming device for improving performance of products

A technology of extrusion forming and horizontal extruding machine, which is applied in the field of horizontal rotary die extrusion forming device, can solve the problems that the mechanical properties of extruded products cannot meet the requirements and other problems, achieve reduction of axial deformation stress and reduce forming load, the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

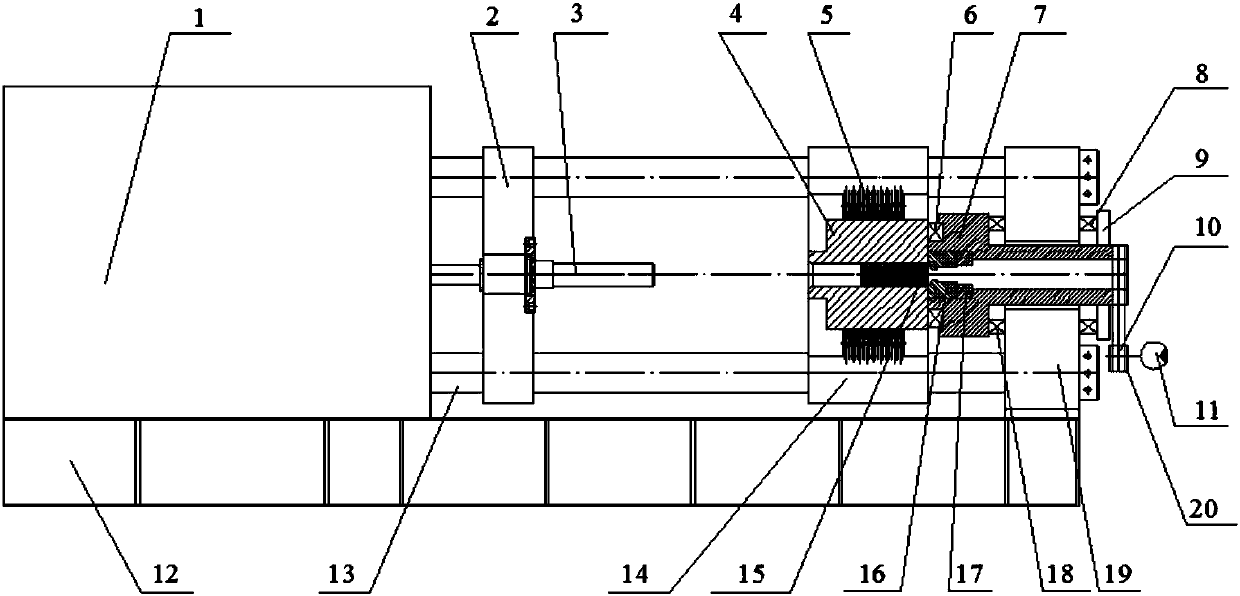

[0027] Specific Embodiment 1: This embodiment is a horizontal rotary die extrusion forming device for improving product performance, which includes a horizontal extruder 1 and a rotary die device 20, and the rotary die device 20 is arranged on the front beam 19 On, the rotary mold device 20 is composed of a servo motor 11, a transmission mechanism 10, a rotary mold cover 7, a mold 16, a mold base 17, a first thrust bearing 6, a second thrust bearing 8, a third thrust bearing 18 and a locking The end cover 9 is composed of the horizontal extruder 1, the movable platform 2, the extrusion cylinder support 14, the front beam 19 and the four expansion columns 13, which are horizontally installed on the upper surface of the frame 12; the movable platform 2 1. Extrusion barrel support 14 and front crossbeam 19 are arranged side by side successively along the length direction of frame 12, and described extrusion barrel support 14 is positioned between movable platform 2 and front cross...

specific Embodiment approach 2

[0029] Embodiment 2: This embodiment is different from Embodiment 1 in that the movable platform 2 slides on four tension columns 13 . Others are the same as in the first embodiment.

specific Embodiment approach 3

[0030] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the transmission mechanism 10 is gear transmission or sprocket transmission. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com