Gasket manufacturing method

A manufacturing method and gasket technology, applied in the field of machinery, can solve the problems of many processing steps, high production cost, increased labor and machine costs, etc., and achieve the effect of simple process, low production cost, and no waste of raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

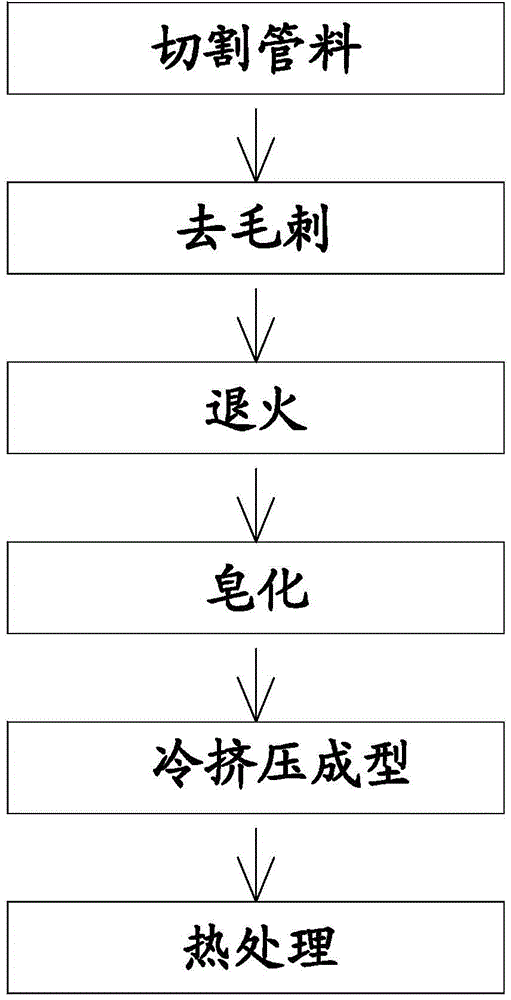

[0036] A kind of manufacturing method of the gasket that material is 40Cr steel, comprises the following steps:

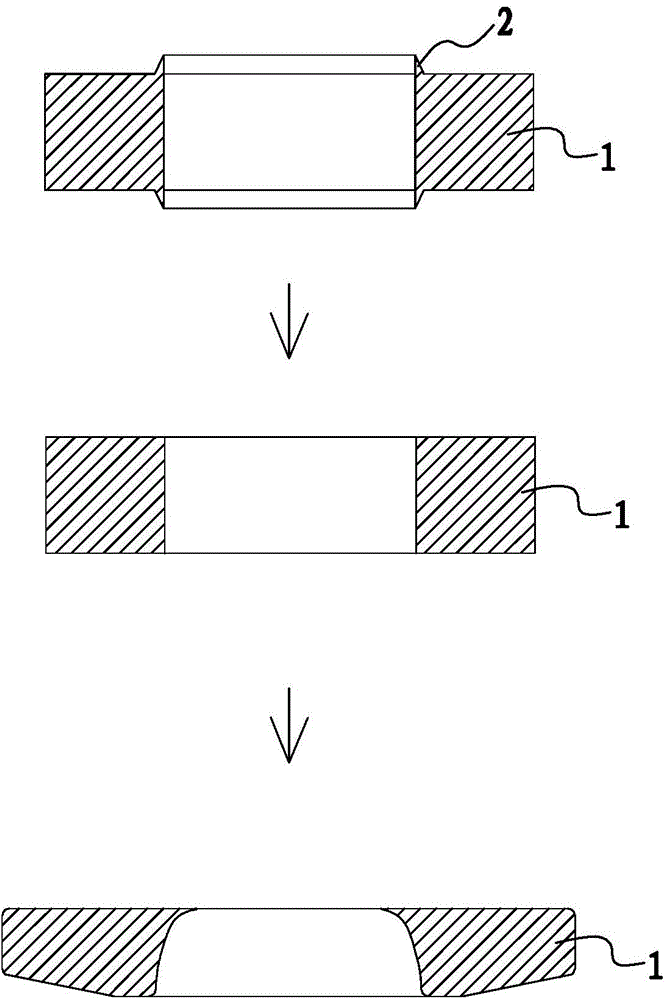

[0037] a. Obtain a ring-shaped workpiece 1: Clamp the steel pipe on the lathe spindle, cut the steel pipe to the required length with a turning tool, and obtain a ring-shaped workpiece 1 to be processed; after cutting, there are burrs 2 remaining at both ends of the workpiece 1 ;

[0038] Thereafter, the ring-shaped workpiece 1 to be processed is deburred 2, specifically, the end of the workpiece 1 is internally chamfered with a lathe.

[0039] As a solution of the deburring 2, only one side of the workpiece 1 is chamfered and deburred during the deburring process.

[0040] As another solution for deburring, both sides of the workpiece 1 are chamfered and deburred during the deburring process.

[0041] b. After the workpiece 1 is deburred, perform annealing treatment: perform annealing treatment on the annular workpiece 1; first heat the annular workpiece 1 sever...

Embodiment 2

[0055] A kind of manufacturing method of the gasket that material is 40Cr steel, comprises the following steps:

[0056] a. Obtain a ring-shaped workpiece 1: Clamp the steel pipe on the lathe spindle, cut the steel pipe to the required length with a turning tool, and obtain a ring-shaped workpiece 1 to be processed; after cutting, there are burrs 2 remaining at both ends of the workpiece 1 ;

[0057] Thereafter, the ring-shaped workpiece 1 to be processed is deburred, specifically, the two ends of the workpiece 1 are chamfered with a lathe.

[0058] b. After the workpiece 1 is deburred, perform annealing treatment: perform annealing treatment on the annular workpiece 1; first heat the annular workpiece 1 several times, and heat each time to the set temperature within the set time and The set temperature reached after each heating is gradually increased; then the workpiece 1 after several times of heating is cooled several times, and each cooling is cooled to the set temperatu...

Embodiment 3

[0071] A kind of manufacturing method of the gasket that material is 40Cr steel, comprises the following steps:

[0072] a. Obtain a ring-shaped workpiece 1: Clamp the steel pipe on the lathe spindle, cut the steel pipe to the required length with a turning tool, and obtain a ring-shaped workpiece 1 to be processed; after cutting, there are burrs 2 remaining at both ends of the workpiece 1 ;

[0073] Thereafter, the ring-shaped workpiece 1 to be processed is deburred, specifically, the two ends of the workpiece 1 are chamfered with a lathe.

[0074] b. After the workpiece 1 is deburred, perform annealing treatment: perform annealing treatment on the annular workpiece 1; first heat the annular workpiece 1 several times, and heat each time to the set temperature within the set time and The set temperature reached after each heating is gradually increased; then the workpiece 1 after several times of heating is cooled several times, and each cooling is cooled to the set temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com