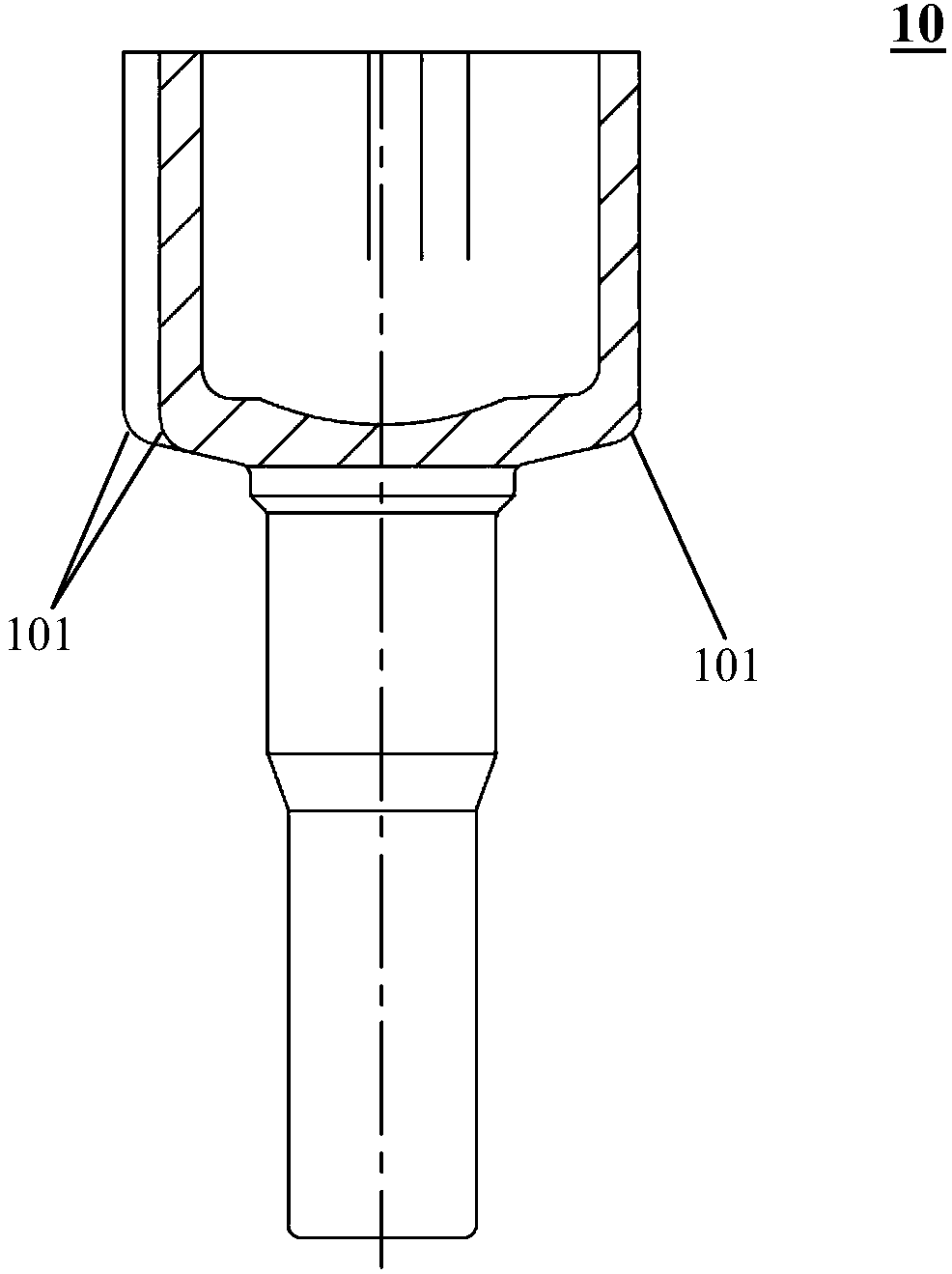

Processing method of universal joint precision forging with R arc end faces

A processing method and technology of universal joints, applied in engine components, mechanical equipment, etc., can solve the problems of insufficient strength, great difficulty, shortened rust prevention effect, etc., and achieve the effect of high strength, excellent torsion resistance, and improved processing technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

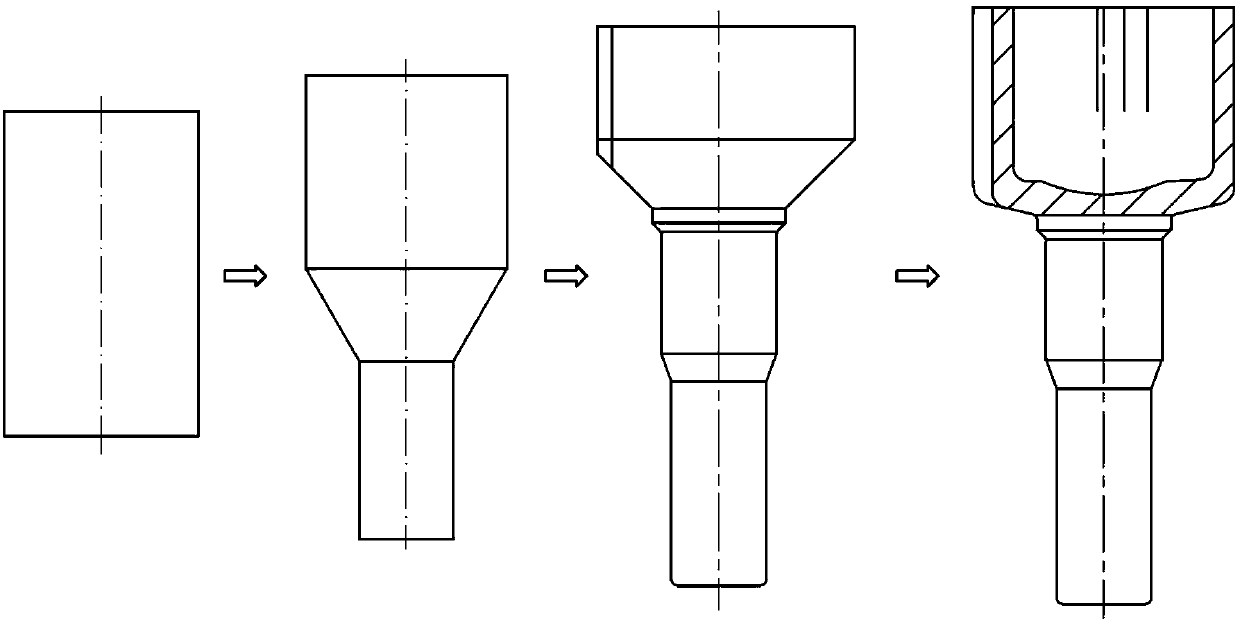

[0025] The process steps and features of the present invention are described in detail below in conjunction with the accompanying drawings.

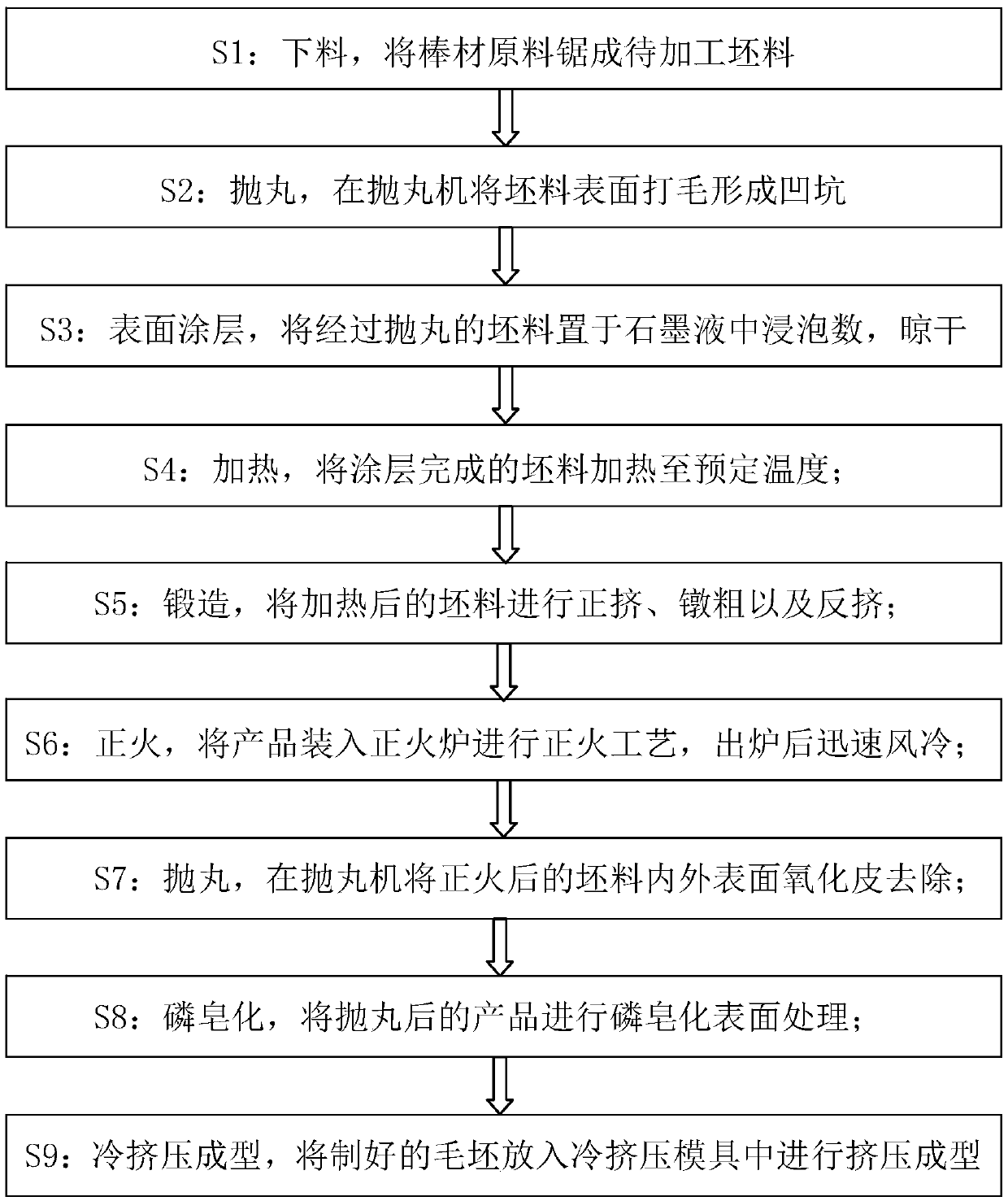

[0026] refer to image 3 The schematic diagram of the technological process of the processing method of a precision forging of a universal joint whose end face is an R arc is shown in the present invention, and the processing method includes the following steps:

[0027] S1: blanking, sawing the bar material into a blank to be processed;

[0028] S2: Shot blasting, adding an appropriate amount of water chestnut sand to the steel shot of the shot blasting machine, and roughening the surface of the blank to form pits;

[0029] S3: surface coating, heat the proportioned graphite solution to 150°C-300°C, soak the shot blasted billet in it for several minutes, and dry it;

[0030] S4: Heating, heating the coated billet to 750-950°C;

[0031] S5: forging, the heated billet is extruded forward, upsetting and reverse extruded in the mold resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com