Food extruder

a technology of food extruder and food, which is applied in the direction of shock absorption devices, elastic dampers, ways, etc., can solve the problems of difficult movement of conventional food extruder for use in another location, inconvenient use of conventional food extruder (b>70/b>), etc., and achieve the effect of convenient us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

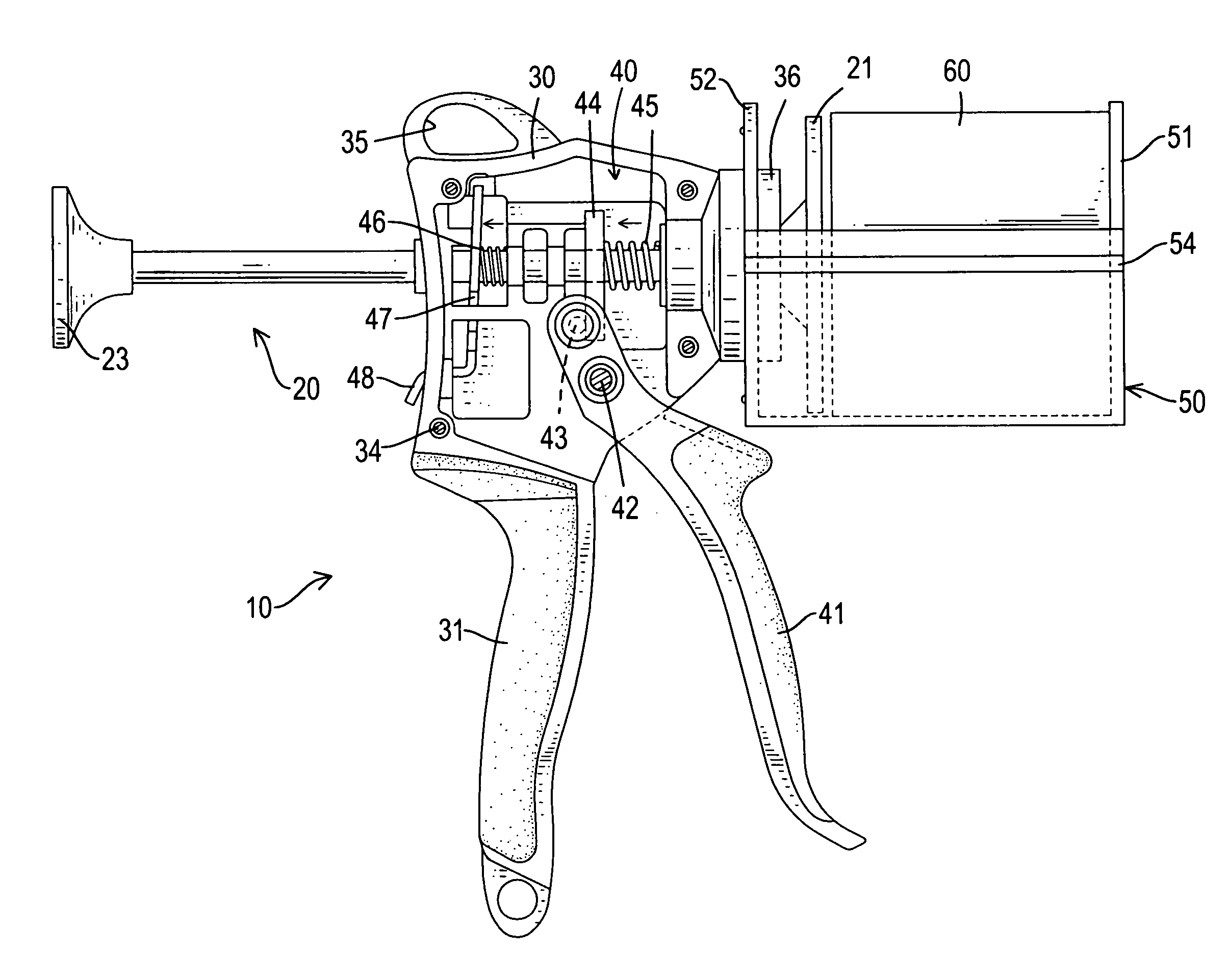

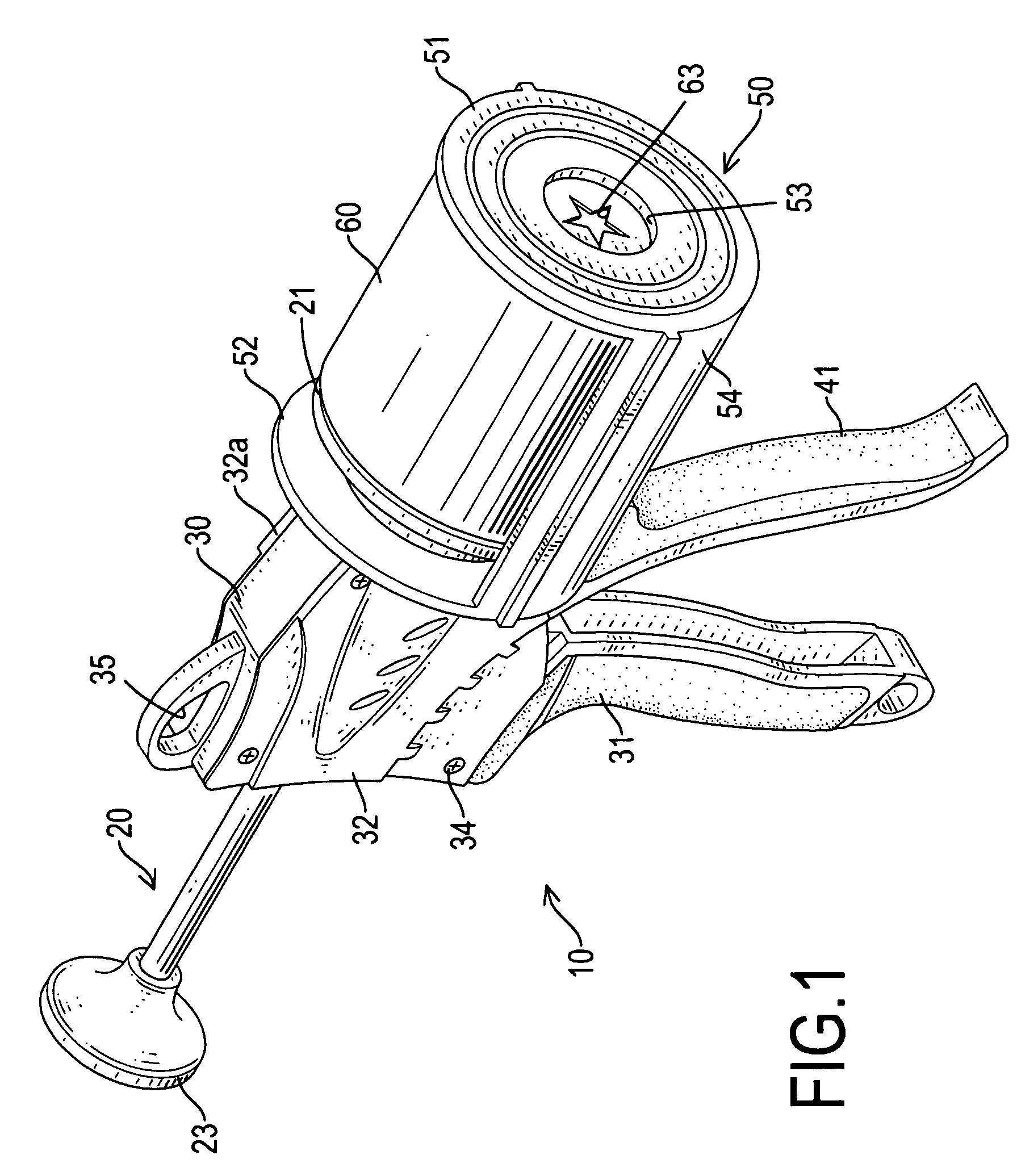

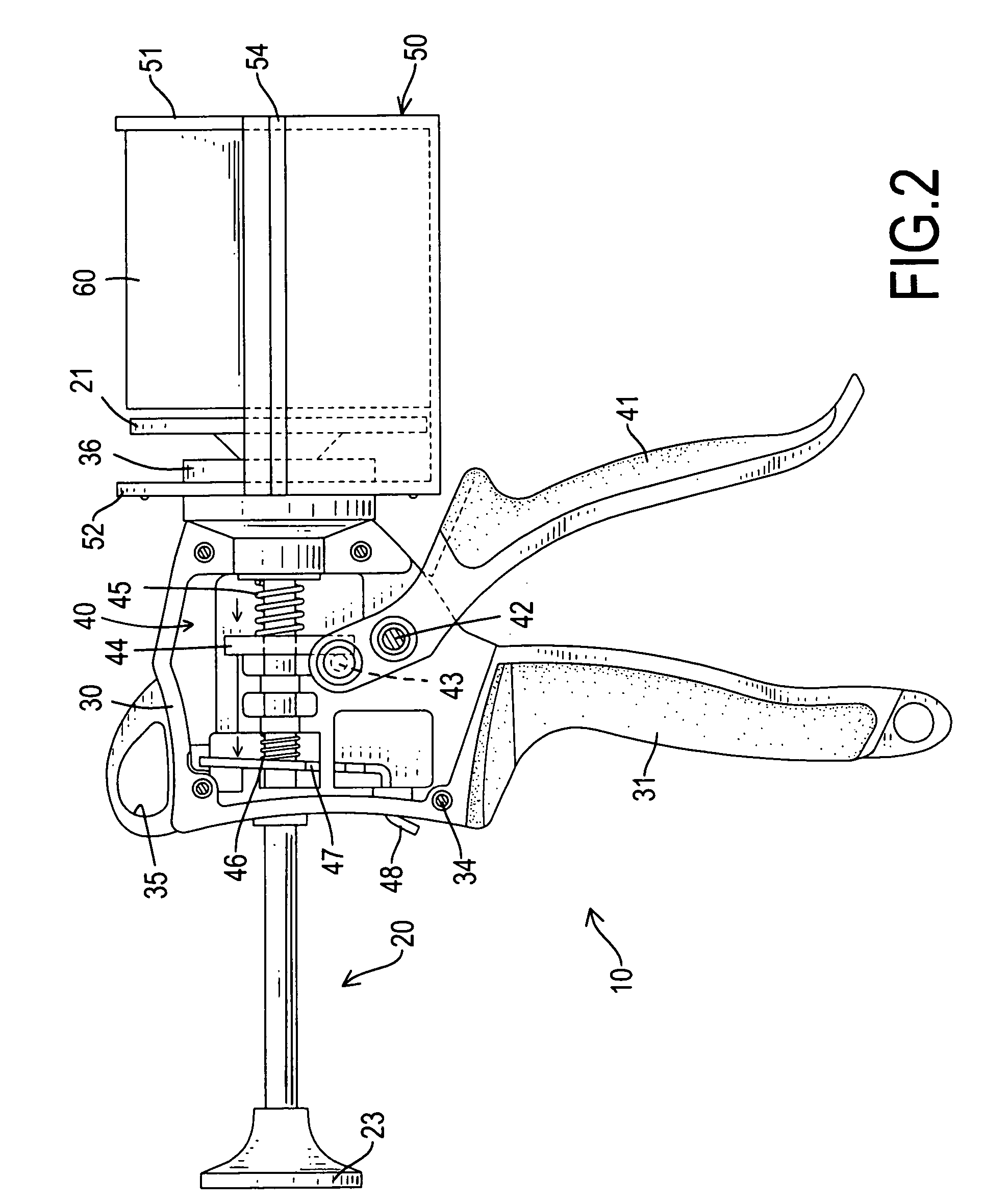

[0013] With reference to FIGS. 1 and 2, a food extruder (10) in accordance with the present invention comprises a body (30), a holder (50), an extruding rod (20), a pressing plate (21) and a driving device (40).

[0014] The body (30) is hollow and has a handle (31), a chamber (not numbered), two side plates (32,32a), a connector (36) and an eye (35). The handle (31) is formed on and extends from the body (30) to allow a user hold the food extruder (10). The chamber is defined inside the body (30) to hold the driving device (40). The two side plates (32,32a) are attached to the sides of the body (30) with screws (34) to close the chamber. The connector (36) is formed on one end of the body (30). The eye (35) is defined through the body (30) to allow the food extruder (10) be hung on a hook or attached to a strap.

[0015] The holder (50) is attached to the body (30) at the connector (36) and comprises a rear plate (52), a supporting frame (54) and a front plate (51). The rear plate (52)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| inclined angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| resilient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com