Metal earphone shell production process

A production process and earphone shell technology, which is applied in the field of earphone manufacturing, can solve the problems of poor product appearance, incapable of one-time molding, and high raw material cost, and achieve the effects of no surface post-processing, simple structure, and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

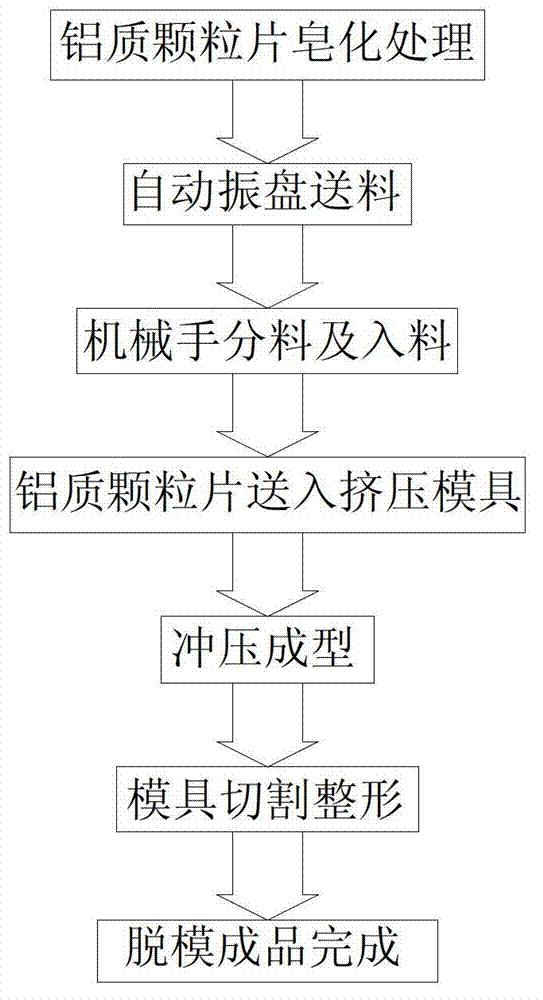

[0033] Such as figure 1 As shown, taking the hollow aluminum earphone shell of φ8×15mm as an example, the production process of the aluminum earphone shell described in this embodiment includes the following steps:

[0034] The first step: material saponification treatment, the processed aluminum pellets are sent to the heating tank, so that a layer of saponified material is attached to the surface of the aluminum pellets, which is used for lubrication during the cold extrusion process of the aluminum pellets, It is easy to release the mold. The saponified material here is zinc phosphate, because the surface of the blank treated with zinc phosphide is attached with a fat lubricant or sodium soap film, and this film is not easy to fall off. When extruding this blank, the pressure is relatively high. Small;

[0035] The second step: feeding, using the automatic vibrating plate in the automatic feeding system to send the processed aluminum pellets to the inlet end of the cold e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com