Bean food biologicalization full nutrition intelligent preparation system

An intelligent preparation system and full-nutrition technology, applied in the field of bean food biochemical full-nutrition intelligent preparation system, can solve the problems of loss and oxidation of soybean nutrients, increase the chance of being oxidized, and affect the quality of production, so as to achieve easy absorption, Low fat content, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

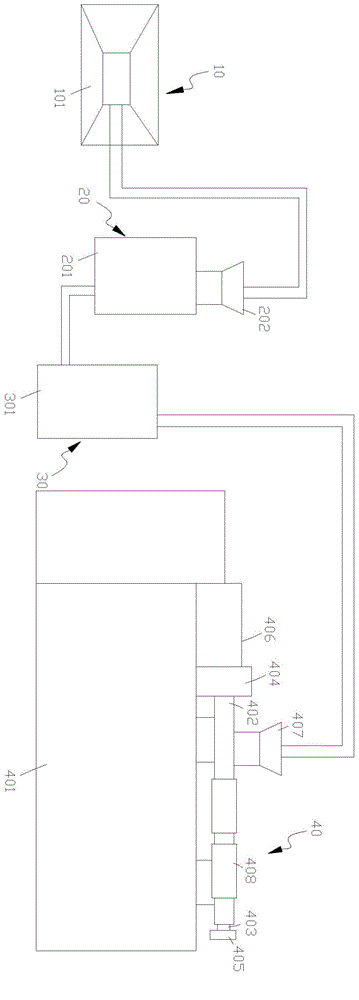

[0028] Such as figure 1 As shown, a bean food biochemical full-nutrition intelligent preparation system includes a biochemical system 10, a crushing system 20, a storage system 30 and a molding system 40;

[0029] The biochemical system 10 mainly includes a biochemical pool 101 for biochemical treatment of beans. The specific method steps are as follows: pour the selected bean raw materials into the biochemical pool 101, pour warm water at 20-26°C, and The water in the biochemical pool 101 should be 15-25cm higher than the raw material, soak for 4-24 hours; the purpose of biochemical treatment is to make the beans expand, improve the activity of the internal substances of the beans, make the nutrients easy to absorb by the human body, and improve the quality of the beans at the same time. The utilization rate of bean dregs will not be produced in the subsequent steps; after the soybeans are biochemically processed in an automatic temperature-controlled biochemical pool at 25°C...

Embodiment 2

[0039] A biochemical full-nutrition intelligent preparation system for soybean food, including a biochemical system 10, a crushing system 20, a storage system 30 and a molding system 40;

[0040] The biochemical system 10 mainly includes a biochemical pool 101 for biochemical treatment of beans. The specific method steps are as follows: pour the selected bean raw materials into the biochemical pool 101, pour warm water at 20-26°C, and The water in the biochemical pool 101 should be 15-25cm higher than the raw material, soak for 4-24 hours; the purpose of biochemical treatment is to make the beans expand, improve the activity of the internal substances of the beans, make the nutrients easy to absorb by the human body, and improve the quality of the beans at the same time. The utilization rate of bean dregs will not be produced in the subsequent steps; after the soybeans are biochemically processed in an automatic temperature-controlled biochemical pool at 25°C, most of the harmf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com