Forming mold unloading vehicle

A forming mold and vehicle-carrying technology, which is applied to trolleys, motor vehicles, multi-axis trolleys, etc., can solve the problems of increasing danger, time-consuming and labor-intensive problems, and achieve the effects of increasing efficiency, saving time and effort in loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

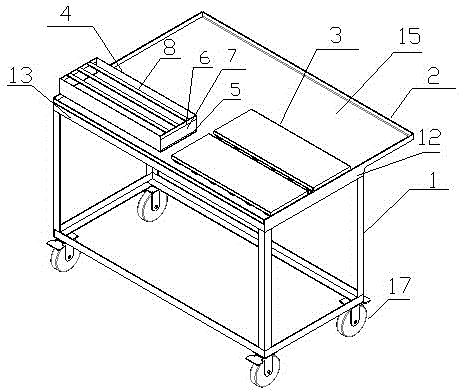

[0020] Such as figure 1 An embodiment of the forming mold unloading vehicle of the present invention is shown, the forming mold unloading vehicle includes an unloading vehicle underframe 1, an unloading vehicle pallet 2 is connected above the unloading vehicle underframe 1, and Place at least one molding die pallet 3 and bending knife pallet 4 above 2.

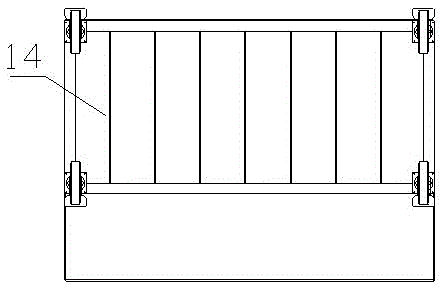

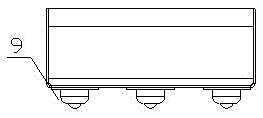

[0021] Such as figure 1 , image 3 As shown, the bending knife tray 4 includes a bending knife tray seat 5 and a bending knife tray frame 6, and a bending knife tray is installed between the bending knife tray seat 5 and the bending knife tray frame 6 Wooden pad 7, the bending knife tray partition 8 is supported on the bending knife tray frame 6 and the first gravity universal ball 9 is housed under the bending knife tray seat 5.

[0022] Such as Figure 5 As shown, the forming mold tray 3 includes a forming mold tray seat 10, a forming mold tray wooden pad 11 is installed above the forming mold tray seat 10, and a secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com