Quickly-detachable temporary supporting system and method for steel structure installation

A temporary support, steel structure technology, applied in building construction, construction, building materials processing and other directions, can solve the problem of affecting the safety and use function of the main structure, easily damaging the main structure base material, and high construction costs, and achieves saving in loading and unloading. Time saving, convenient production, and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

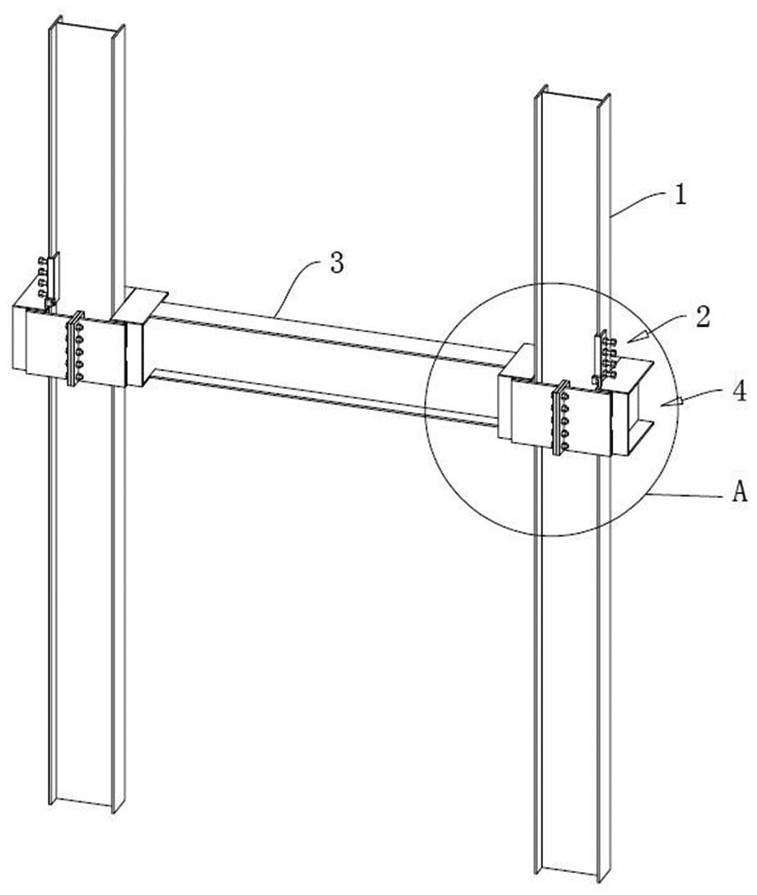

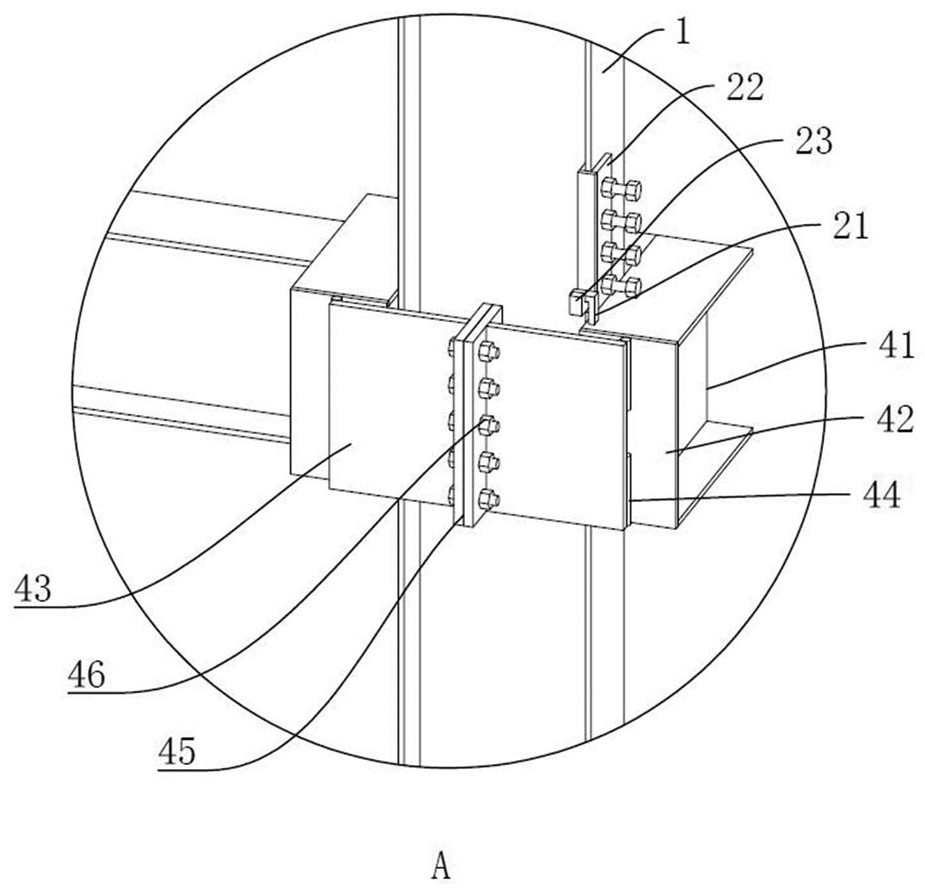

[0028] Such as figure 1 and figure 2 As shown, the present invention provides a temporary support system and method for installing a quick-detachable steel structure. The temporary support system includes a steel column 1, a support assembly arranged between the two steel columns 1, and an anti-fall structure connecting the steel column 1 and the support assembly. Component 2; steel column 1 is made of H-shaped steel.

[0029] The support assembly is assembled and welded by section steel, steel plate, and rotating shaft 44. It includes a beam 3 arranged between two steel columns 1 and installation clips 4 respectively fixed at both ends of the beam 3. The installation clip 4 is sleeved on the steel column 1. and match the size of the steel column 1. The mounting clip 4 includes a mounting sleeve 41 set on the steel column 1. The mounting sleeve 41 is welded and fixed to the beam 3. The mounting sleeve 41 is U-shaped as a whole and is formed by welding three pieces of steel....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com