A portable gas cylinder apron loading and unloading tool

A loading and unloading tool and portable technology, which is applied in the field of loading and unloading of gas cylinder anti-vibration rubber rings, can solve the problems of time-consuming and labor-intensive operation in the early stage of equipment, labor-consuming and labor-consuming, and low assembly efficiency, and achieve the effects of simple production, low cost and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

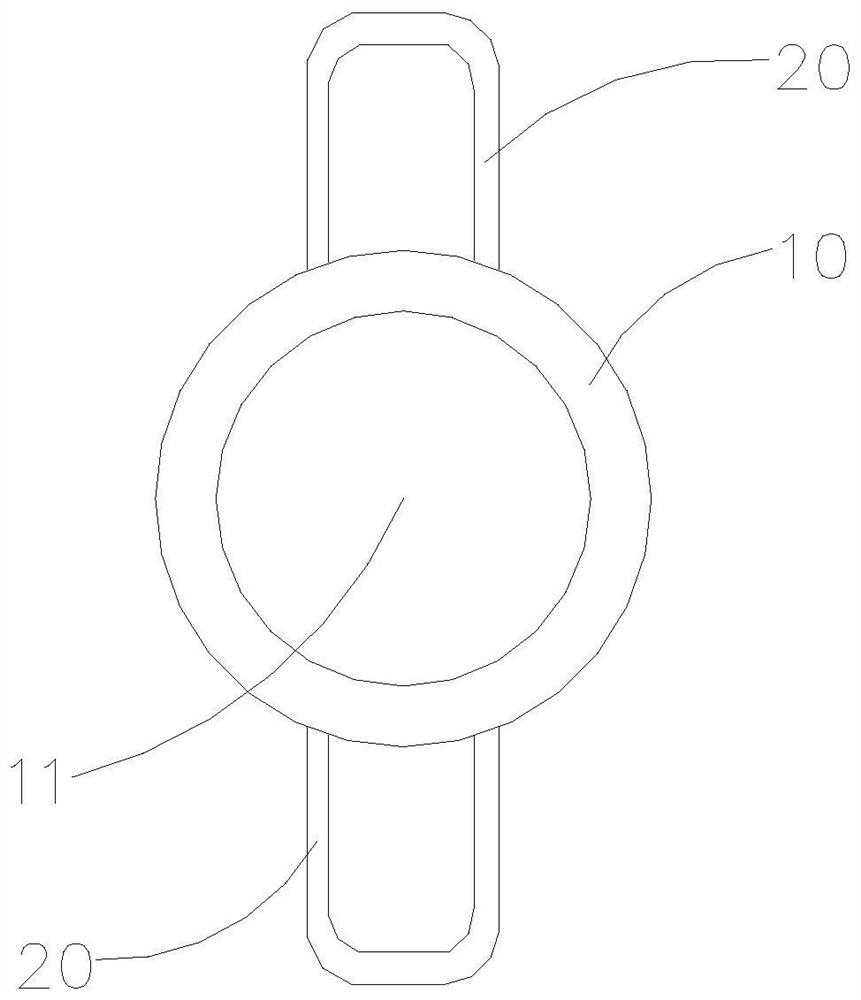

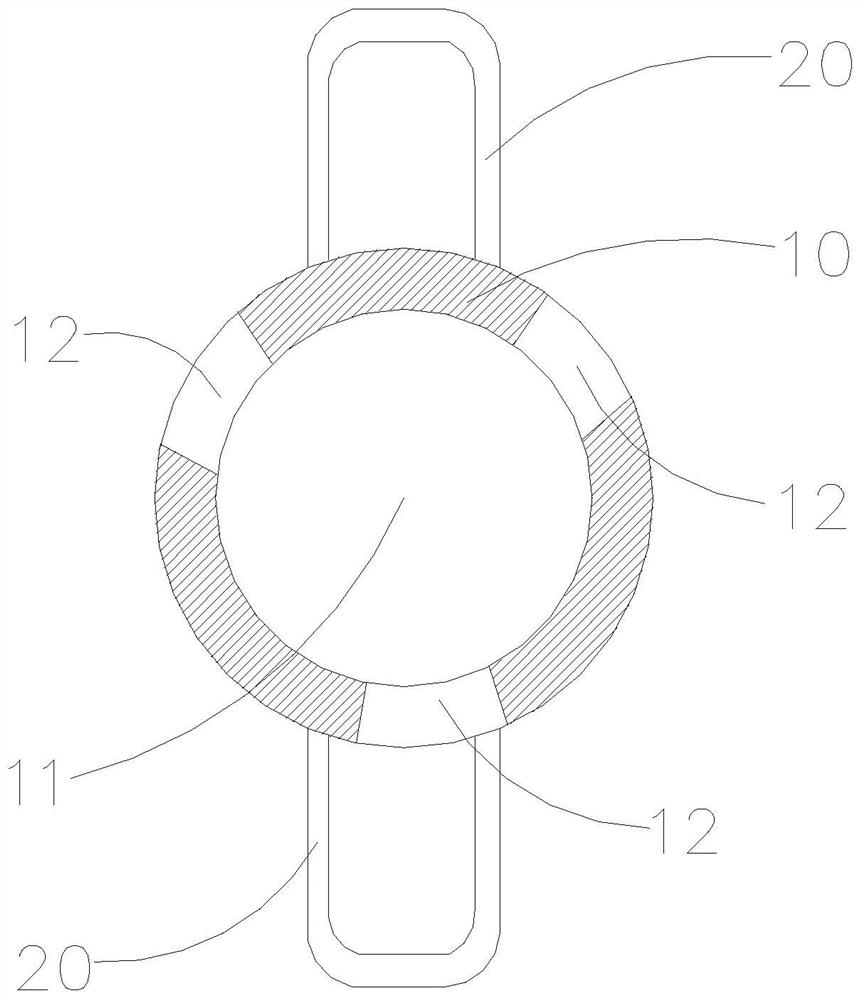

[0032] Please refer to Figure 1-Figure 7 , figure 1 It is a structural schematic diagram of a portable gas cylinder apron handling tool in an embodiment of the present invention. The portable gas cylinder apron handling tool includes a tool body 10 for being sleeved on the gas cylinder body and two ends of the tool body 10 The pull ring 20, the inside of the tool body 10 is provided with a through hole 11 through which the body of the gas cylinder can pass.

[0033] In some preferred embodiments, the tool body 10 is an annular plate structure, and the annular surface of the tool body 10 corresponds to the rubber ring and pushes the rubber ring from the head of the gas cylinder to the bottom of the bottle or the bottom of the bottle. body.

[0034] In some preferred embodiments, the tool body 10 is evenly provided with at least two strip holes 12, the strip holes 12 can pass through the slide plate 30, and the slide plate 30 is provided with holes for the screw rod 40 to pas...

Embodiment 2

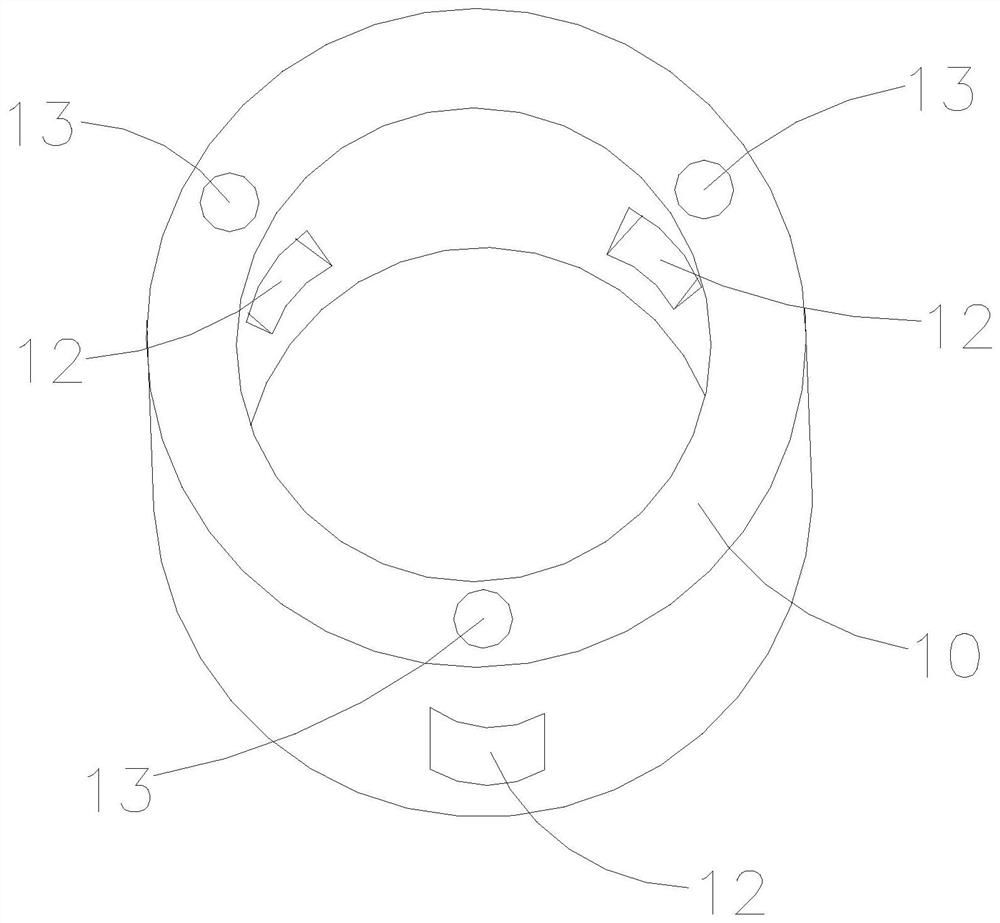

[0038] On the basis of Embodiment 1, the tool body 10 is evenly provided with three strip holes 12, the strip holes 12 can pass through the slide plate 30, and the slide plate 30 is provided with a slide plate hole through which the screw rod 40 can pass. , the tool body 10 is provided with a screw hole 13 at the upper and lower ends of the bar hole 12, and the screw 40 is fixed by a nut 50 after passing through the tool body 10 and the slide plate 30, which can meet the demand of a gas cylinder with a larger diameter .

Embodiment 3

[0040] On the basis of Embodiment 1, the tool body 10 is evenly provided with five strip holes 12, the strip holes 12 can be passed through by the slide plate 30, and the slide plate 30 is provided with a slide plate for the screw rod 40 to pass through hole, the tool body 10 is provided with a screw hole 13 at the upper and lower ends of the strip hole 12, and the screw 40 is fixed by a nut 50 after passing through the tool body 10 and the slide plate 30, which can meet general diameter and larger diameter cylinder requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com