Simple steel cylinder packaging box

A container grid, steel cylinder technology, applied in packaging, transportation and packaging, containers and other directions, can solve the problems of easy dumping, high production cost, and many materials, so as to avoid dumping or skewing, reduce production costs, and avoid water accumulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

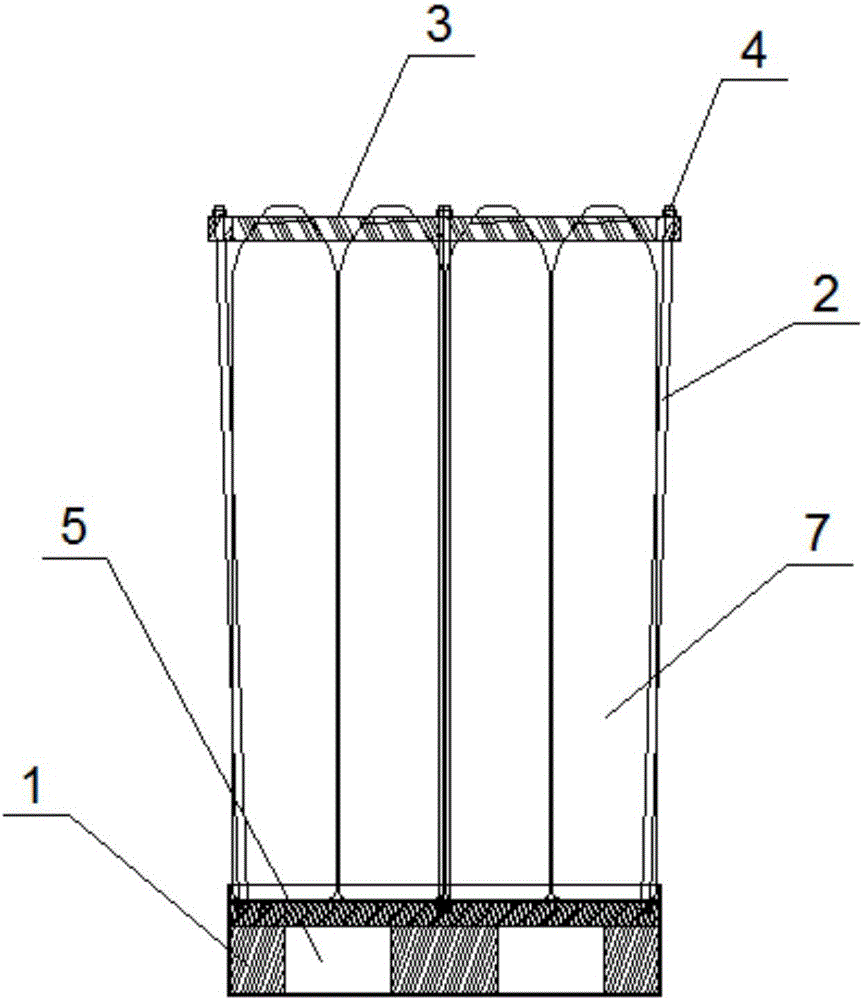

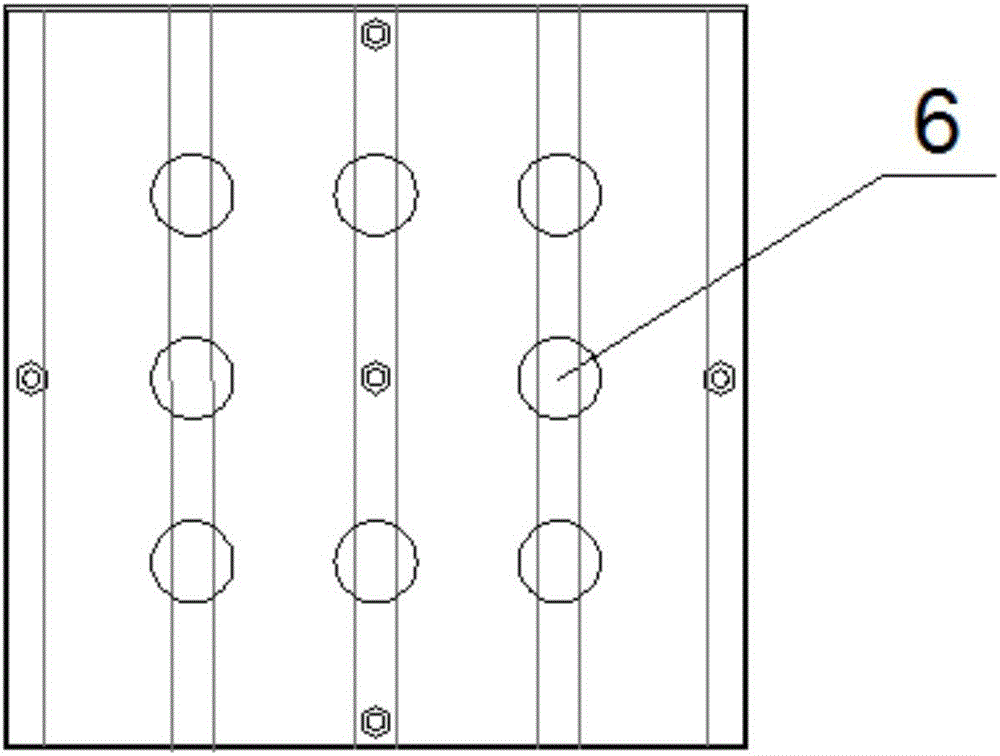

[0020] The invention provides a simple container for steel cylinders. Its working principle is to make the whole device simpler through the design of the bottom plate, fixed rod and top cover. When dumping during transportation, adjust the position of the top cover with the pull rod bolt to ensure that the top cover is close to the shoulder of the steel cylinder, so that the device is suitable for the collection of steel cylinders of different specifications, so as to reduce production costs, facilitate loading and unloading, facilitate transportation, and avoid dumping of steel cylinders and reduce the workload of staff.

[0021] The present invention will be described in further detail below in conjunction with examples and specific implementation methods.

[0022] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com