Large-diameter cutter head fixing frame

A fixed frame and large diameter technology, applied in the field of mechanical manufacturing and processing, can solve the problems of reduced flexibility, troublesome disassembly, high manufacturing cost, etc., to achieve the effect of ensuring working height and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

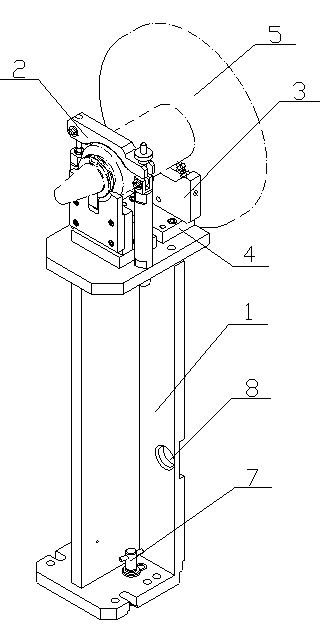

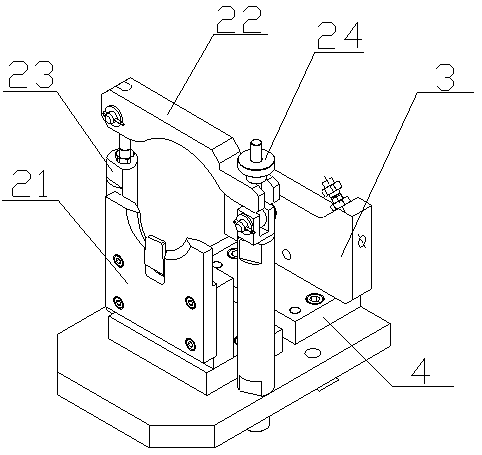

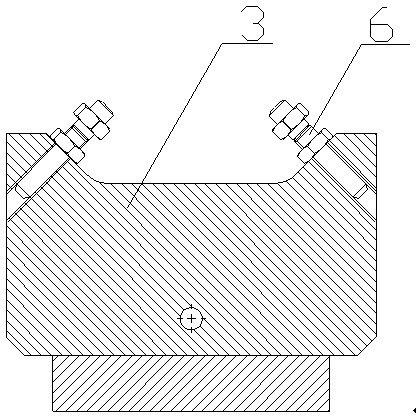

[0016] Please refer to the attached Figure 1 to Figure 4 , the embodiment of the present invention includes:

[0017] A large-diameter cutter head fixing frame, comprising: a support seat 1, a locking mechanism 2 for clamping a cutter head 5, and a limit seat 4; the support seat 1 is an I-shaped structure, and the upper working surface is processed with Positioning holes and screw holes can fix the locking mechanism 2 and the limit seat 4; the limit seat 4 is connected with the cutter shaft support 3 by fasteners; the position of the cutter shaft support 3 is parallel to the The above-mentioned locking mechanism 2, and the height of its support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com