Online gluing device for fiber loop manufacturing based on capillarity

A technology of optical fiber ring and capillary action, which is applied to the device and coating of the surface coating liquid, which can solve the problems of long working hours, disturbing the optical fiber in the product, and high requirements for the sizing device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the drawings and specific examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

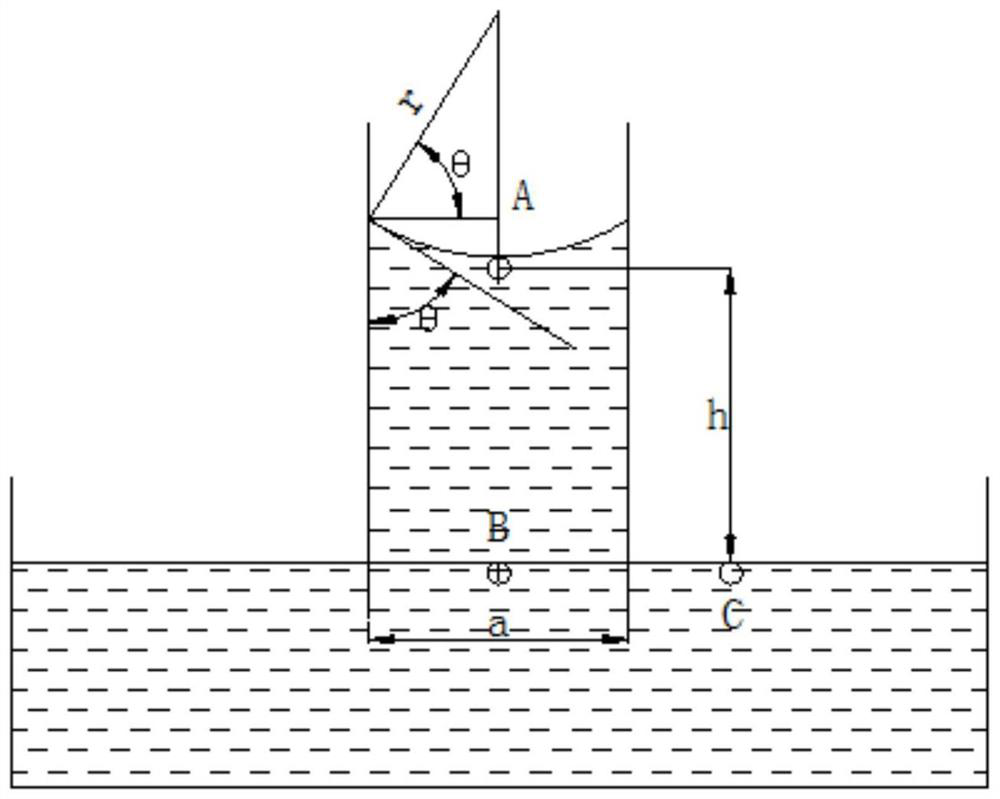

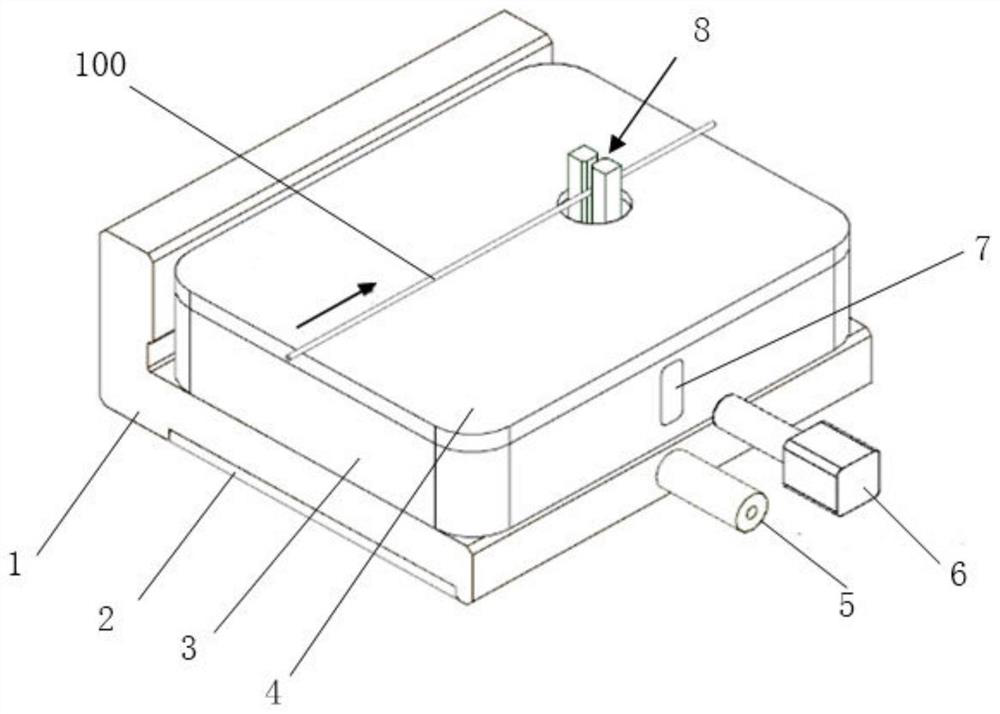

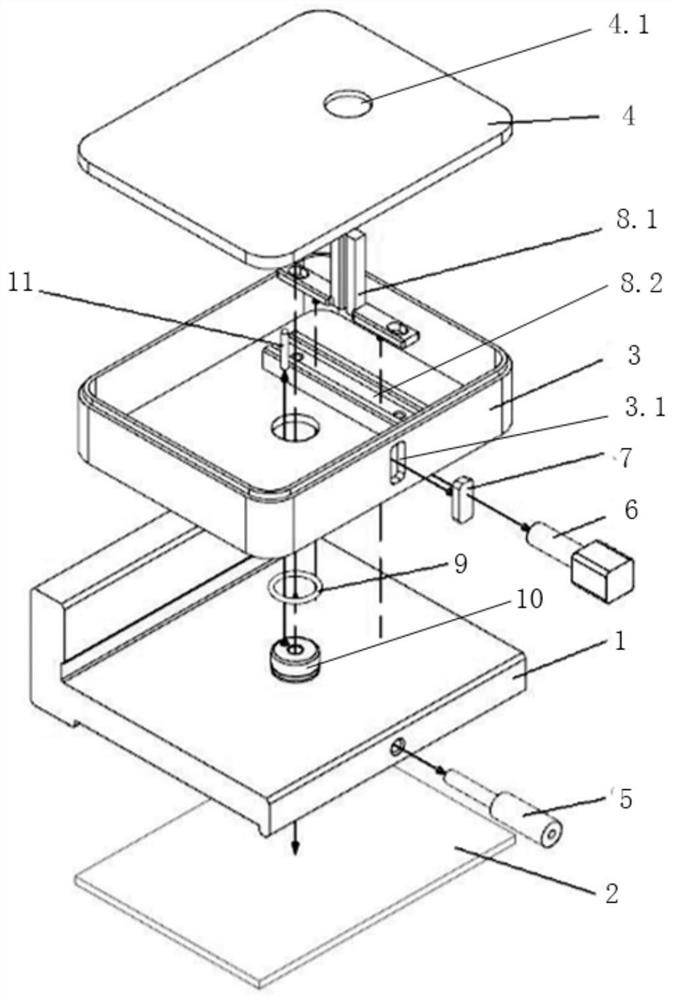

[0023] The present invention proposes an online gluing device for making optical fiber rings based on capillary action. Its functional part is to use a small slit made of a material that can be soaked by glue and a glue pool with a liquid level sensor. It is infiltrated by glue, so when the slit is placed in the glue pool filled with glue, the glue will climb to a certain height in the slit due to capillary action, when the optical fiber is lower than the height of the glue in the slit. When the height passes through the slit, the optical fiber in the slit is immersed in the glue. As the optical fiber travels through the slit, the glue in the slit is continuously taken away by the optical fiber. At the same time, due to the exi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com