Adjustable fixture of wire-cut electrical discharge machine tool

A technology for cutting machine tools and EDM wires, which is applied in the field of EDM, can solve the problems of machine tool clamping and long workpiece workpiece difficulties, and achieve the effects of ensuring clamping accuracy, simple and flexible clamping, and reducing clamping time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

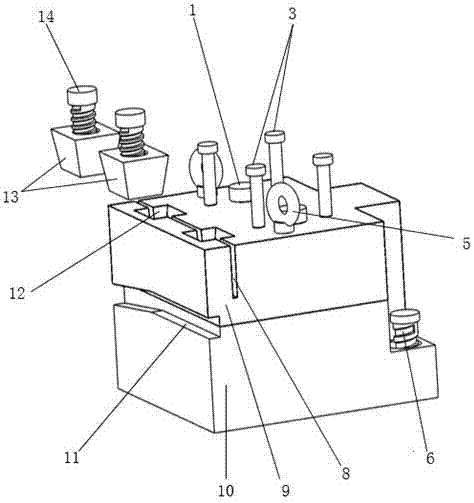

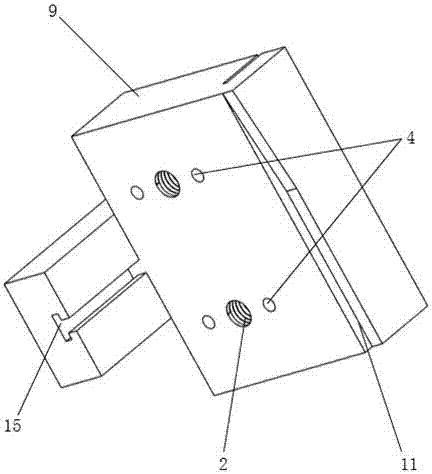

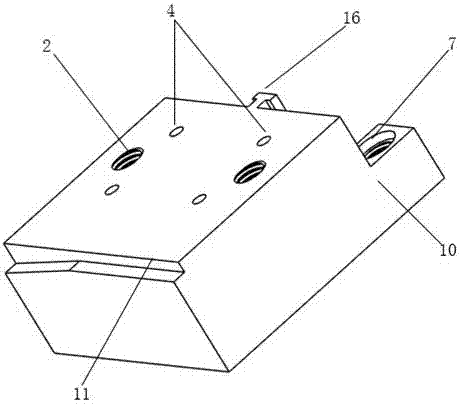

[0015] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing, see Figure 1-7 As shown, the wire electric discharge cutting fixture includes a base 10 and a pressing plate 9 arranged on the base. The pressing plate 9 is locked on the base 10 through the pressing bolt 1. The pressing bolt 1 is used to compress the workpiece to be processed. The base The upper side of the front end surface of 10 and the lower side of the front end surface of the pressing plate 9 are respectively provided with corresponding elongated strips, and one end has a curved groove structure. The base 10 of the wire cutting fixture and the pressing plate 9 are closely connected together to form a The workpiece clamping groove 11 for clamping the workpiece; the upper side of the front end of the pressing plate 9 in the height direction also has a fine-tuning seam 8 whose gap width can be fine-tuned. Fine-tuning block placement groove 12 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com