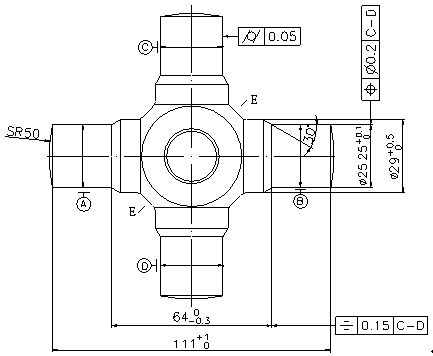

Universal joint crossing shaft blank cold extrusion processing technology

A processing technology, a cross-axis technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of folding and sharp edges, scarring, blank surface cracks, etc., to avoid sharp edges and improve the utilization rate of steel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: a kind of universal joint cross shaft blank cold extrusion process, comprises the following steps:

[0042] 1) Cut the raw materials into material sections, grind the surface through centerless grinding, and inspect the cracks; spray the qualified material sections with water-based graphite lubricant, and dry the water-based graphite lubricant;

[0043] 2) The first annealing heat treatment: heat the material section to 845°C, keep it warm for 10 hours, cool to 330°C, take it out of the oven, and cool to room temperature;

[0044] 3) The material section is subjected to shot blasting treatment, followed by phosphating and saponification treatment;

[0045] 4) Place the material section on the hydraulic press for cold extrusion, and get a cross round rod blank in the mold;

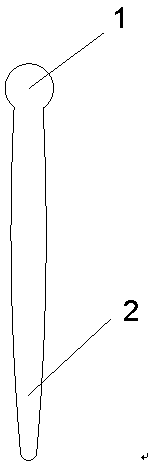

[0046] 5) Use a low-carbon steel rod with a round rod head to hammer and grind the arc-shaped burr of the cross round rod-shaped blank, so that it is bent and turned to one side to for...

Embodiment 2

[0050] Embodiment 2: a kind of universal joint cross shaft blank cold extrusion processing technology, comprises the following steps:

[0051] 1) Cut the raw materials into material sections, grind the surface through centerless grinding, and inspect the cracks; spray the qualified material sections with water-based graphite lubricant, and dry the water-based graphite lubricant;

[0052] 2) The first annealing heat treatment: heat the material section to 855°C, keep it warm for 10 hours, cool to 350°C, then take it out of the furnace, and cool it to room temperature;

[0053] 3) The material section is subjected to shot blasting treatment, followed by phosphating and saponification treatment;

[0054] 4) Place the material section on the hydraulic press for cold extrusion, and get a cross round rod blank in the mold;

[0055] 5) Use a low-carbon steel rod with a round rod head to hammer and grind the arc-shaped burr of the cross round rod-shaped blank, so that it is bent and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com