Semi-cured food extrusion machine

A twin-screw extruder and extrusion sleeve technology, applied in the field of food processing machinery, to achieve the effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

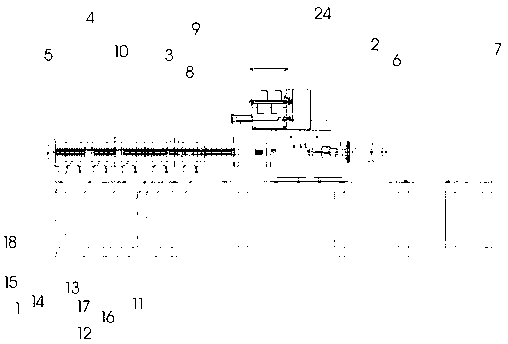

[0015] The semi-cooked twin-screw extruder includes a machine base 1, a gear box 2, and an extrusion device 3. The extrusion device 3 is installed on the machine base 1. The extrusion device 3 has two screws 4 and an extrusion sleeve 5. The root screw 4 is arranged in the extruding sleeve 5, the gear box 2 has a main gear and two transmission gears, the two transmission gears are all engaged with the main gear, and the rear ends of the two screws 4 are respectively connected to the gear box through spline sleeves 2, the main gear can drive the two transmission gears to rotate in the same direction, and the main gear in the gearbox 2 is connected with the motor 7 arranged at the rear end of the support through a coupling 6. A feed inlet 8 is arranged on the upper rear end of the extruding sleeve 5, and five temperature-controlled water tanks 10 are arranged outside the extruded sleeve 5. The extruding device areas surrounded by the five temperature-controlled water tanks 10 cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com