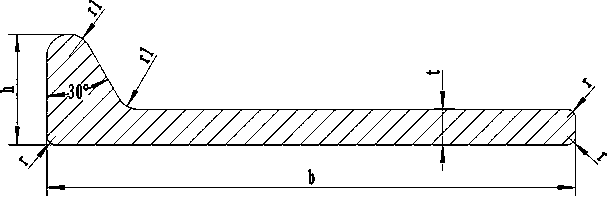

Ball flat steel double hole die extrusion molding method

A technology of extrusion molding and flat bulb steel, which is applied in the direction of metal extrusion, metal extrusion dies, metal containers to be extruded, etc., can solve the problem of different performance, multiple deformation passes, uneven performance of bulb flat steel, etc. problem, to achieve the effect of improving the lubrication effect and reducing the bending degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

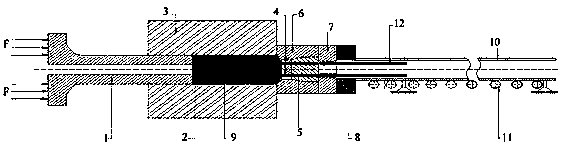

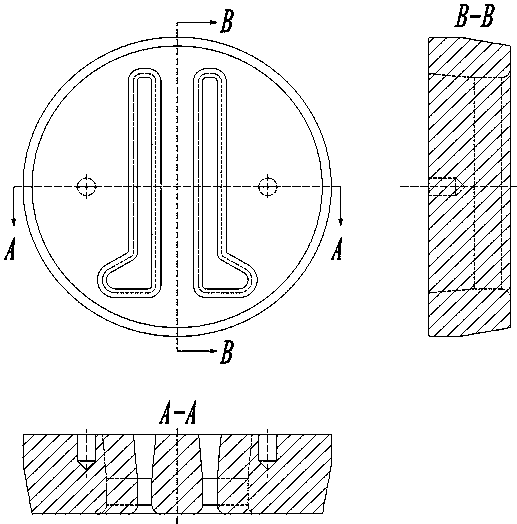

Method used

Image

Examples

Embodiment 1

[0060] The invention provides a double-hole mold extrusion molding method for spherical flat steel, which specifically includes the following steps:

[0061] (1) Material: austenitic stainless steel

[0062] Outer diameter: Φ222 mm, outer diameter tolerance -2~0mm

[0063] Length: 450mm

[0064] Arc angle: R35mm

[0065] Surface roughness: ≤R3.2μm

[0066] (2) Blank heating

[0067] Ring furnace heating has 1 preheating section, 3 heating sections and 1 holding section, among which the preheating section is 900±20°C, and the target temperature of the three heating sections and holding section is 950±10°C.

[0068] Induction heating has 1 heating section and 2 holding sections. The heating section has a power of 480kW and is heated to a target temperature of 1180±10°C. 220kW.

[0069] (3) Lubrication

[0070] The outer surface of the billet is lubricated by domestic Tianli Chuang GW8, the glass pad is GD19, and the inner hole of the glass pad is in the shape of a special...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com