Multi-channel cooling die

A cooling mold and channel technology, applied in slaughtering, food forming, food science and other directions, can solve the problems of stability, leakage to the outside, coolant leakage, etc., to achieve easy assembly, little cross-contamination, and simple disassembly work. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] To produce extruded food products, such as imitation fibrous shredded pork, requires an extruder capable of shearing and compressing the constituent ingredients, and a conveyor that sends these materials to a cooling die. An extruder can have one or more screws. These are well known and will not be described here.

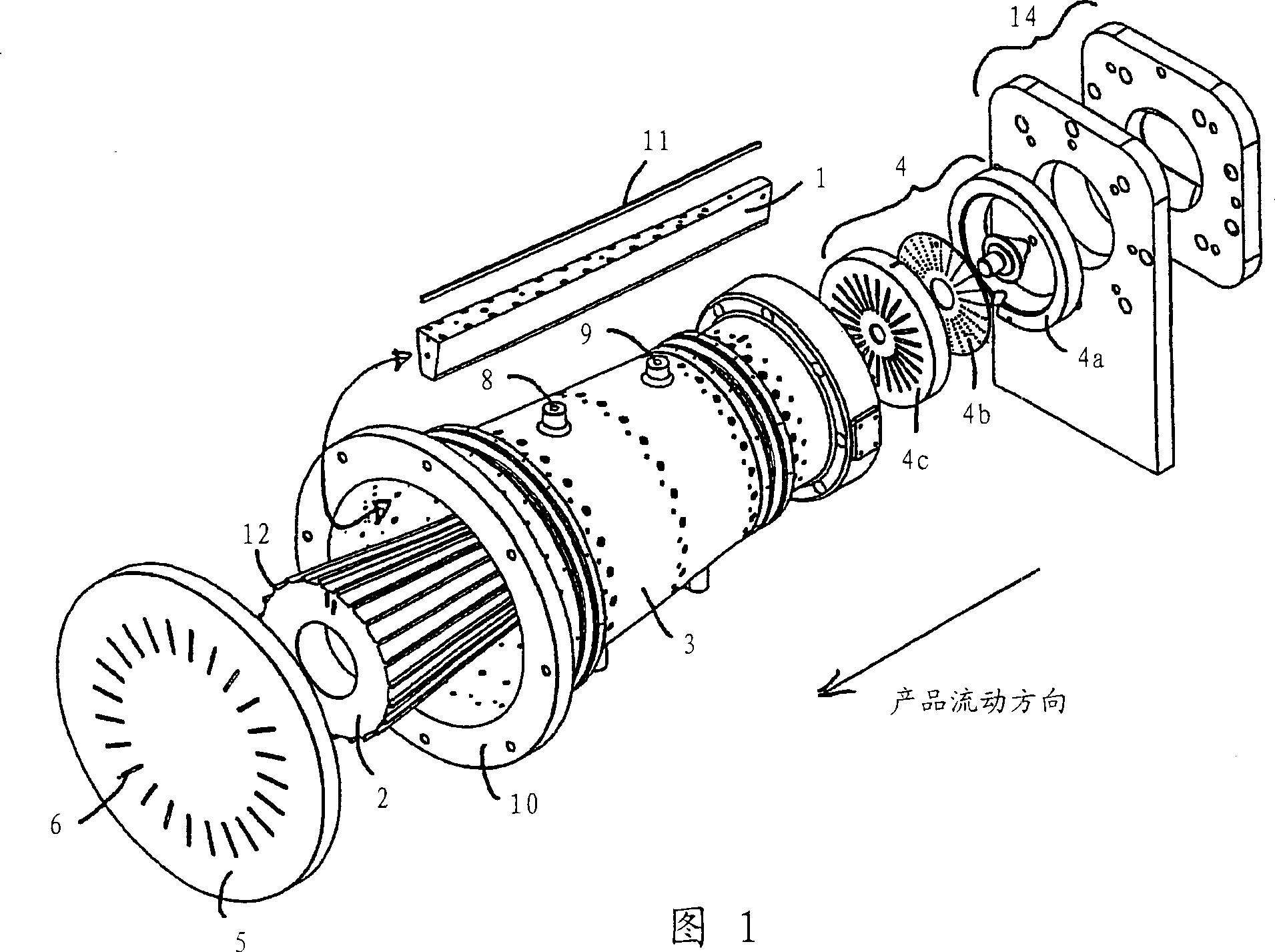

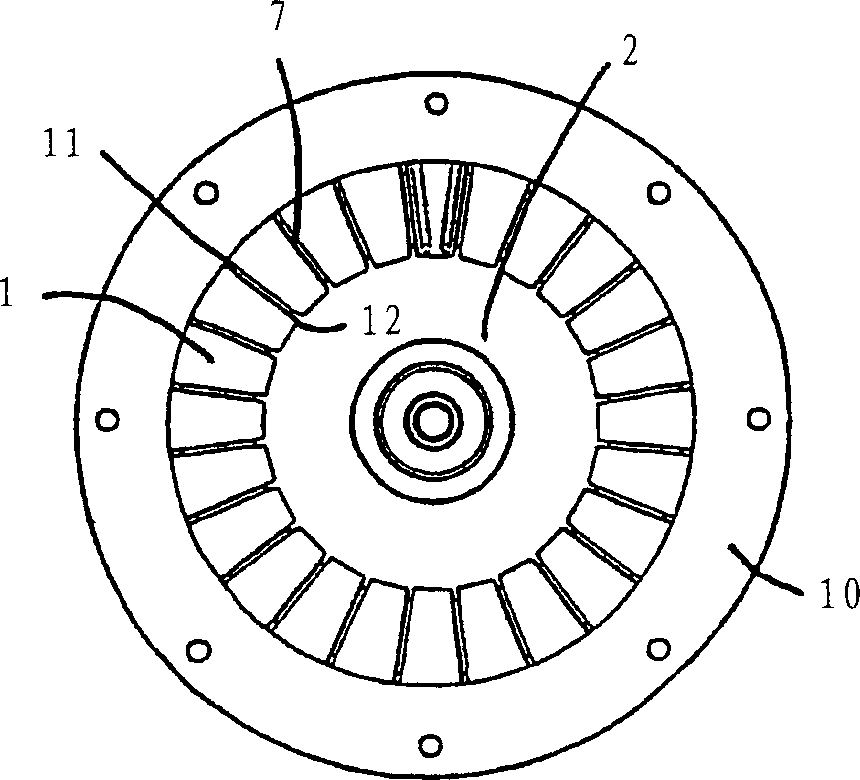

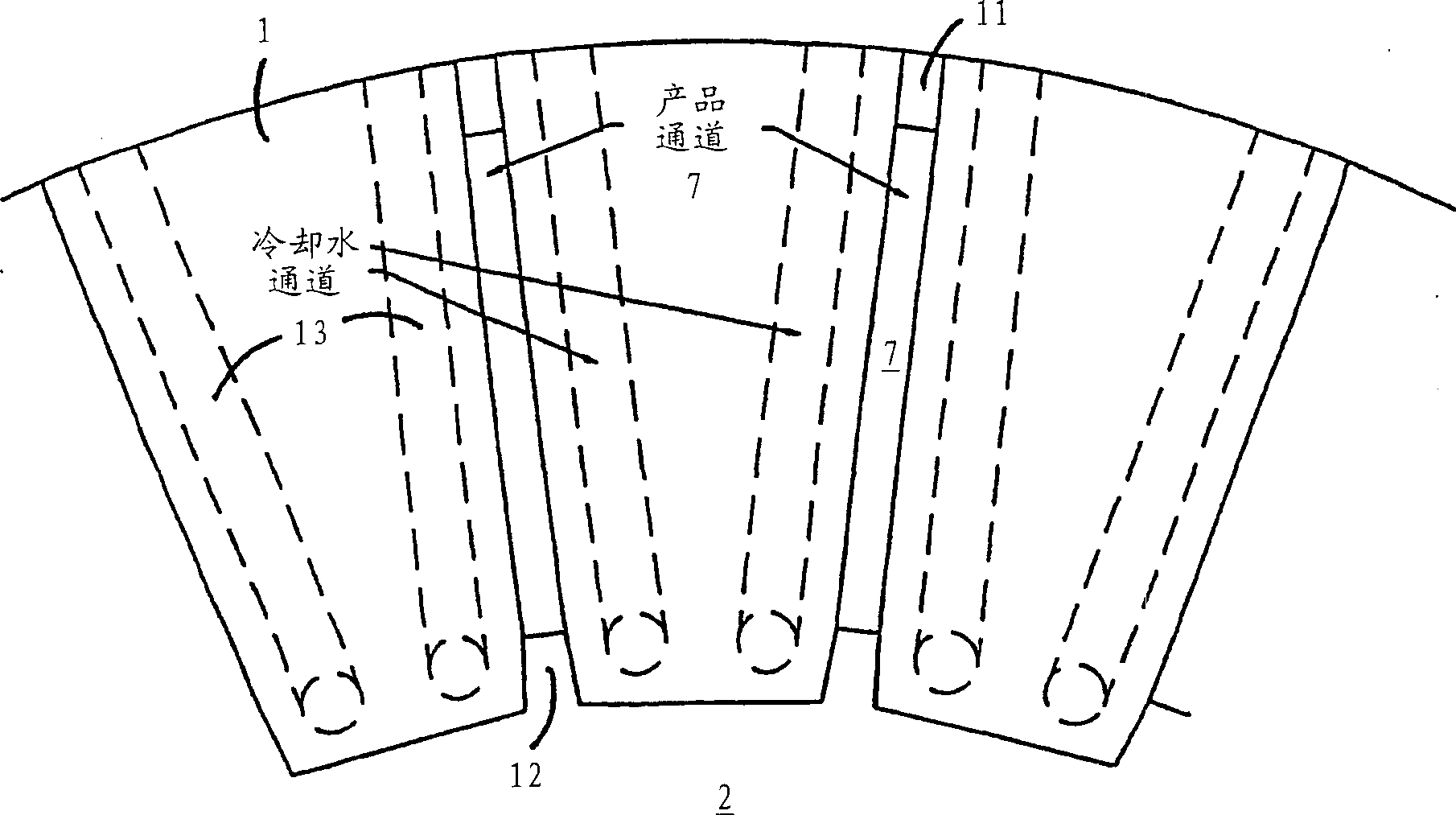

[0052] A cooling die assembly for use at the delivery end of a high-moisture protein food extruder according to the present invention is shown in exploded perspective view in FIG. 1 . The cooling mold assembly mainly includes: a multi-piece mold body composed of a plurality of cooling wedges 1 arranged radially around a central core 2 . This body is in turn housed in a tubular holding sheath 3 . The extruded flow sent from the extruder is introduced into the inlet end of the cooling die through the flow distribution device 4 composed of diverging cone 4a, orifice plate 4b and groove plate 4c. The distribution device 4 serves to ensure a uniform inflow of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com