Hot-extrusion production line of prestressed anchorage device clamping piece

A production line and hot extrusion technology, applied in the direction of manufacturing tools and other manufacturing equipment/tools, etc., can solve the problems of incorrect placement of blanks, multiple processes, and easy punching of punches, etc., to achieve reduced replacement time, accurate outer cone size, The effect of saving mold steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

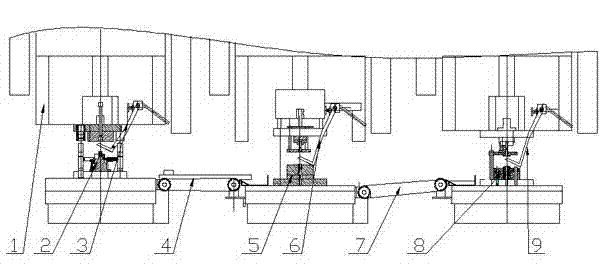

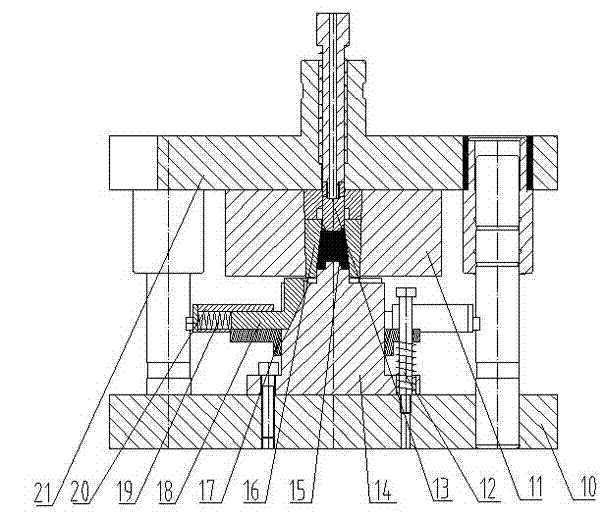

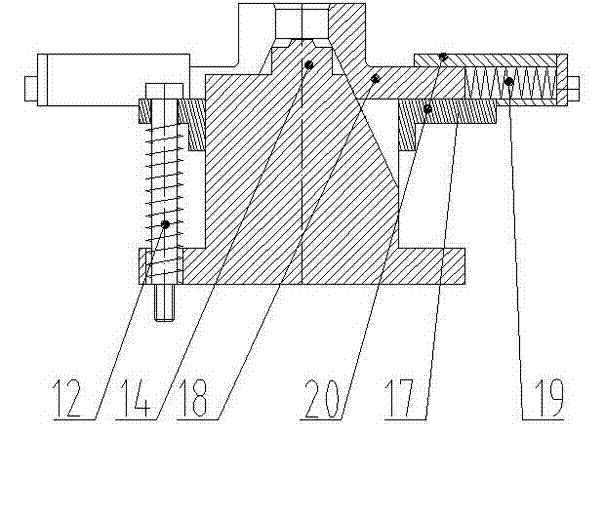

[0015] like figure 1 As shown, the upsetting extrusion billet mold 2, the composite extrusion mold 5, and the floating positioning punching and shaping mold 8 are sequentially fixed on the workbench and slider of the press 1 by bolts, and mechanical parts are installed on the front side of each press 1. Material receiving hands 3, 6, 9; the process of this embodiment is that the heated bar is put into the upsetting extrusion billet mold 2 to obtain a cone with a centering hole. After the upsetting is completed, the mechanical material receiving hand 3 is linked with the slider. When the slider reaches the top dead center, the mechanical material receiving hand 3 reaches under the upper die to catch the billet, and sends it into the compound extrusion die 5 through the conveyor chain 4, and the semi-finished product with upper and lower blind holes is obtained through compound extrusion, and is also passed through the mechanical connection. After the material hand 6 catches the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com