Forging method for forming through holes of working clamping plates by hot extrusion

A technology of hot extrusion and working clamps, which is applied in the field of forging, can solve the problems of small impact and cutting force on the surface of the workpiece, low work efficiency, poor surface quality of the workpiece, etc., and achieve the goal of reducing forging difficulty, improving processing efficiency, and quick replacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] A method for forging a hot-extruded through-hole of a working clip includes the following steps:

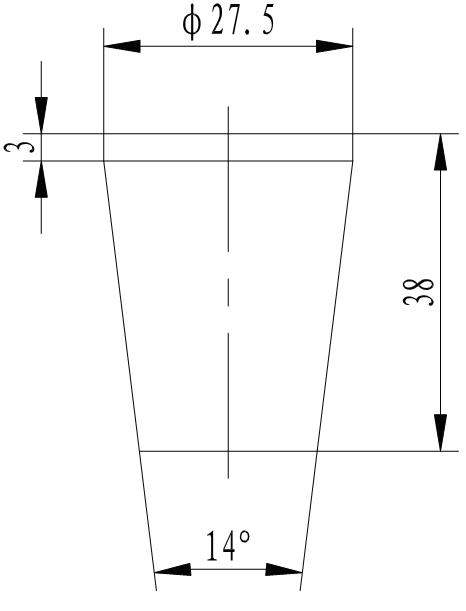

[0047] (A) Blanking: using a sawing machine to cut the material, the size of the blank is φ25×33.5;

[0048] (B) Deburring: Use a grinder to deburr the blank in step (A), remove burrs, oil stains, rust spots and dirt on the blank, and separate the blanks according to different furnace numbers after the blanks are cleaned;

[0049] (C) Heating: put the clean billet in step (B) into an intermediate frequency heating furnace for heating, and the heating temperature is 1100±20°C;

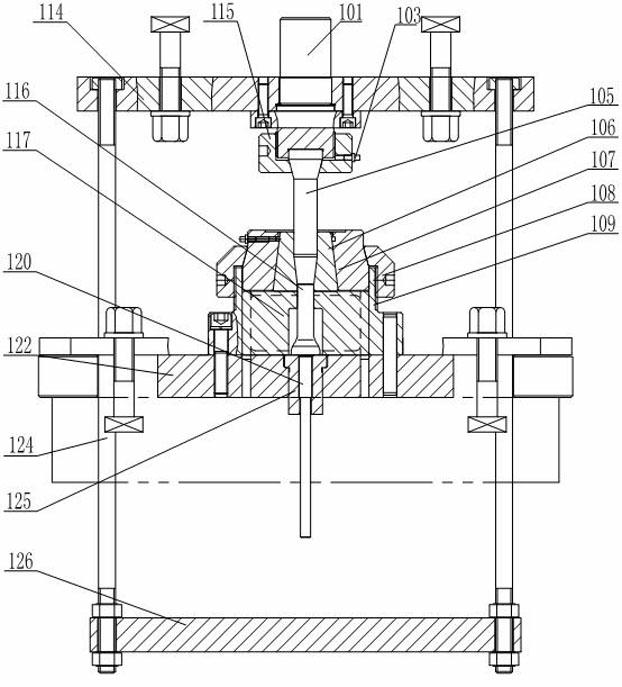

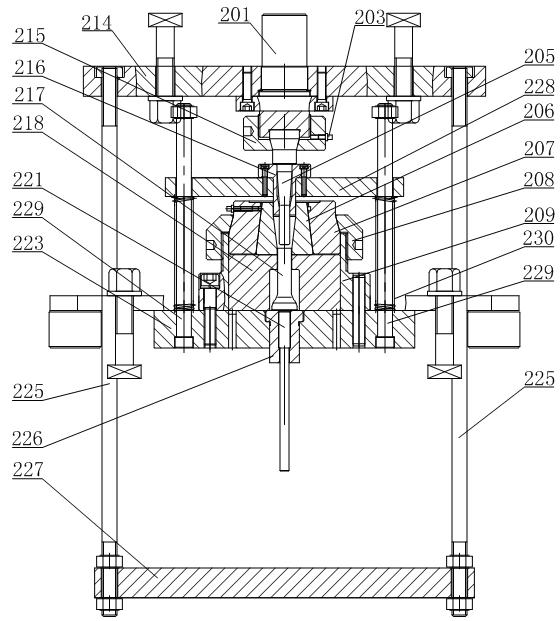

[0050] (D) Pre-forging: Use a 100-ton punch press to complete the following steps within 5S:

[0051] (D1) Install the mold correctly, check whether the punch and die are aligned, and whether the closing height is correct. After the punch sleeve enters the die for 20mm, fine-tune according to the height of the product;

[0052] (D2) Turn on the circulating cooling water, and adjust the flow rate of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com