Cold extrusion forming die fixture and cold extrusion forming method for aluminum rear covers of cellphones

A mobile phone back cover and cold extrusion technology, applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., can solve the problems of low operating safety factor, high manufacturing cost, and slow production speed , to achieve high operational safety factor, improve the internal structure of the metal, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following examples are only used to illustrate the present invention, but not to limit the protection scope of the present invention.

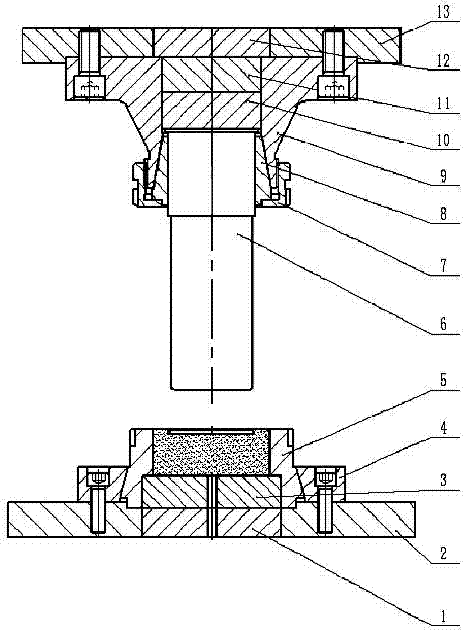

[0026] figure 1 As shown in , a cold extrusion mold fixture for the back cover of an aluminum material mobile phone according to the present invention can be divided into two parts: a die and a punch. The die part includes a die 5, a compression ring 4, a die Template 2, block A1 and block B3, the die part is fixed on the die plate 2 with the compression ring 4, and then the die part is fixed on the worktable of the machine tool with connecting bolts;

[0027] The punch part includes the punch 6, the compression ring 4, the punch seat 9, the nut 7, the cushion block C10, the cushion block D11, the cushion block E12 and the die seat plate 13, and the punch 6 is loaded into the punch seat 9 and pressed with Clamp it with the ring 8 and the nut 7, then fix the punch base 9 on the mold base plate 13, and finally fix the punch part on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com