Manufacturing process of ball valve for gas meter pipeline

A gas meter pipeline and manufacturing process technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of product sand holes, air holes, casting process pollution, high cost, etc., achieve smooth surface, good metal performance, and reduce fracture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

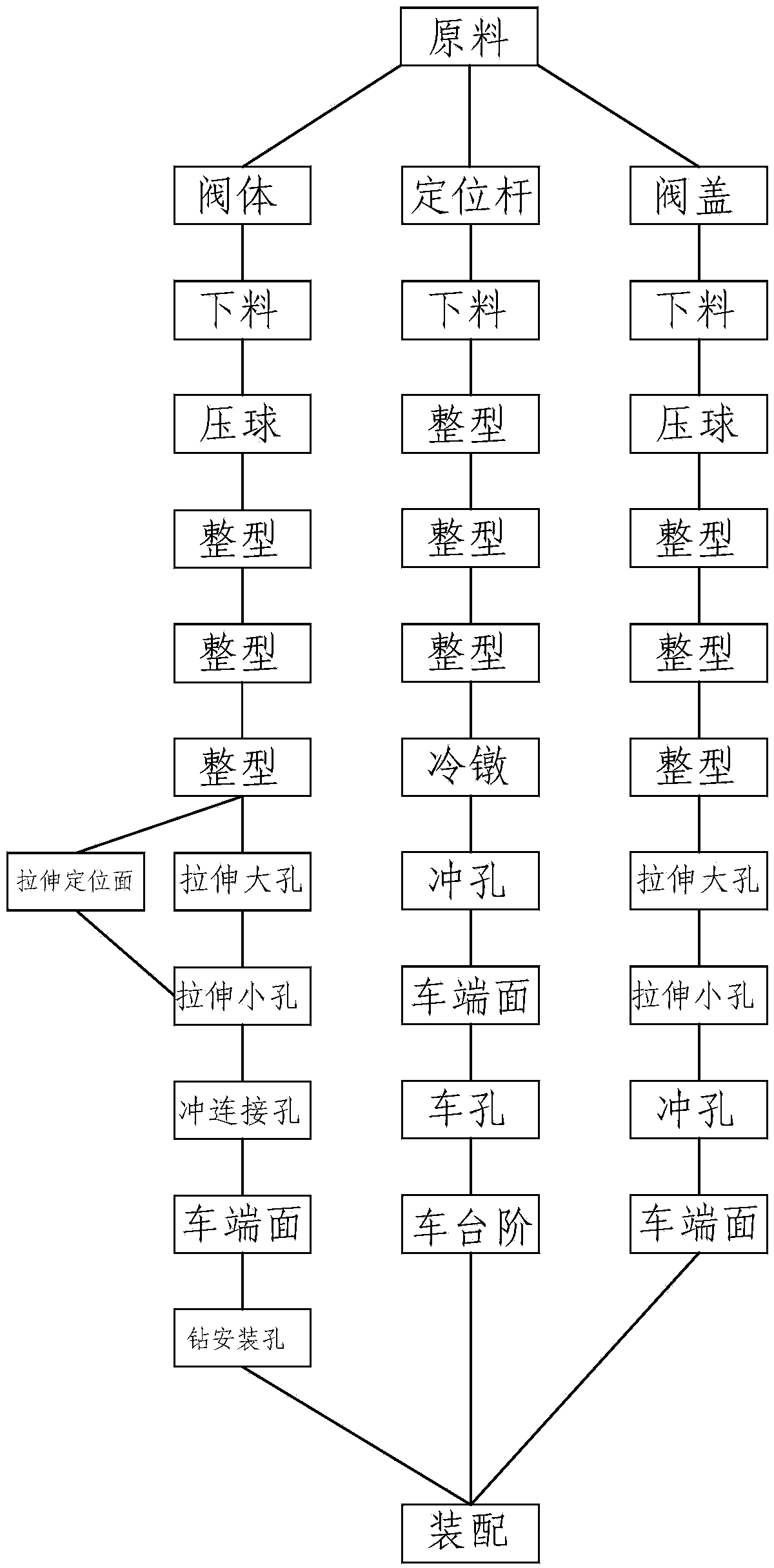

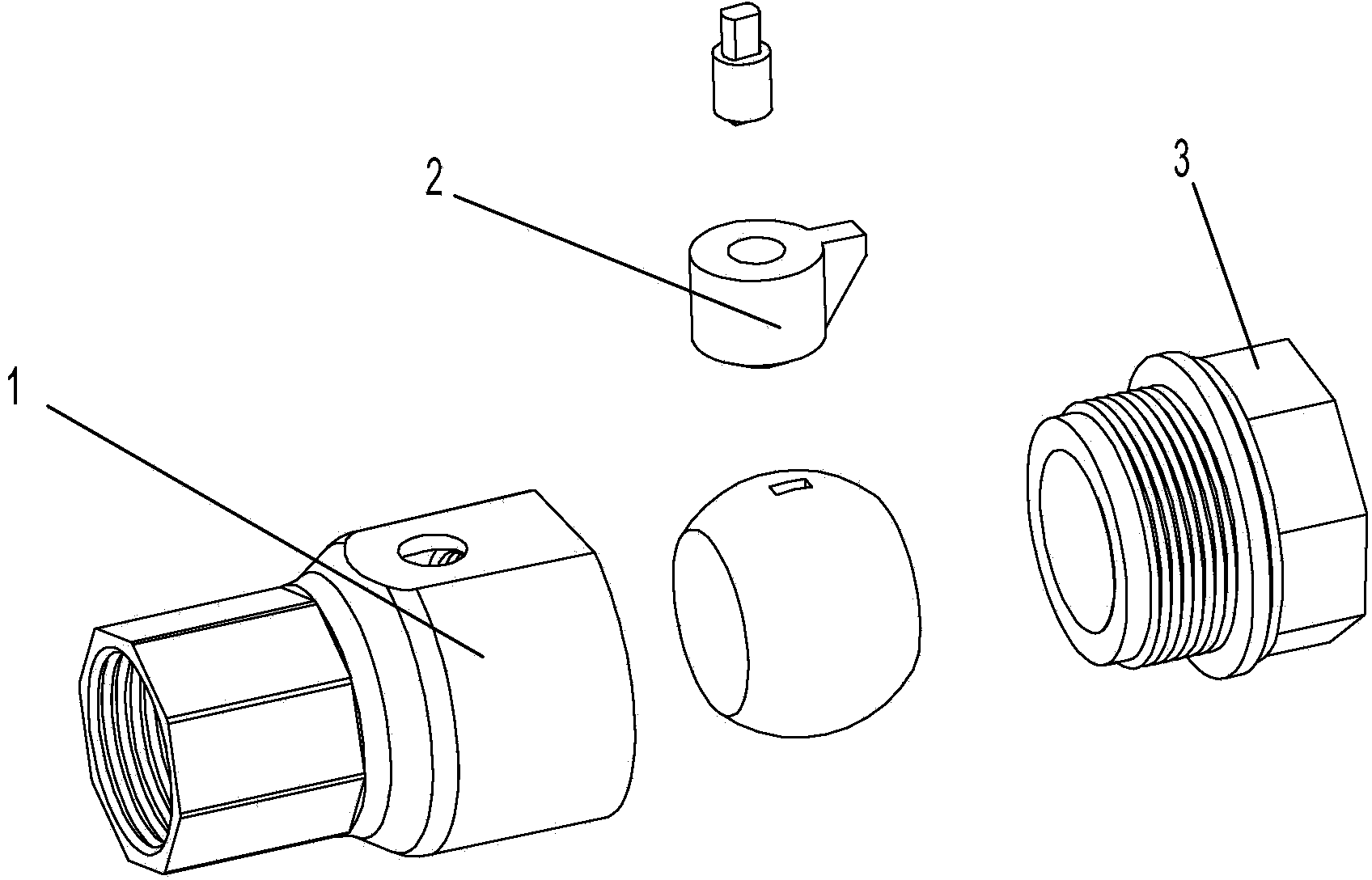

[0041] refer to Figure 1 to Figure 2 The embodiment of the manufacturing process of the ball valve for the gas meter pipeline of the present invention will be further described.

[0042] A process for manufacturing a ball valve for a gas meter pipeline, comprising the following steps:

[0043] Step 1, manufacture valve body 1:

[0044] In the cold heading machine mold, add the raw materials used to make the valve body 1, process the valve body 1 blank, and then press the blank to make the raw material into a spherical blank; in the cold heading machine mold, the spherical blank is processed three times Reshaping, gradually cold heading out the outline of the valve body 1; stretching one end of the outline of the valve body 1, cold heading extrudes the ball valve cavity and the positioning surface located on the circumference of the valve body 1; the other end of the outline of the valve body 1 Stretch and extrude the ball valve interface by cold heading; in the punching mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com