Spray-coating-free scraping-resistant polypropylene material for automobile and preparation method thereof

A polypropylene material, spray-free technology, applied in the field of polymer materials, can solve the problems of unfavorable scratch resistance, poor scratch resistance, easy ash absorption, etc., to increase scratch resistance and surface metal effect, size Good stability and good scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

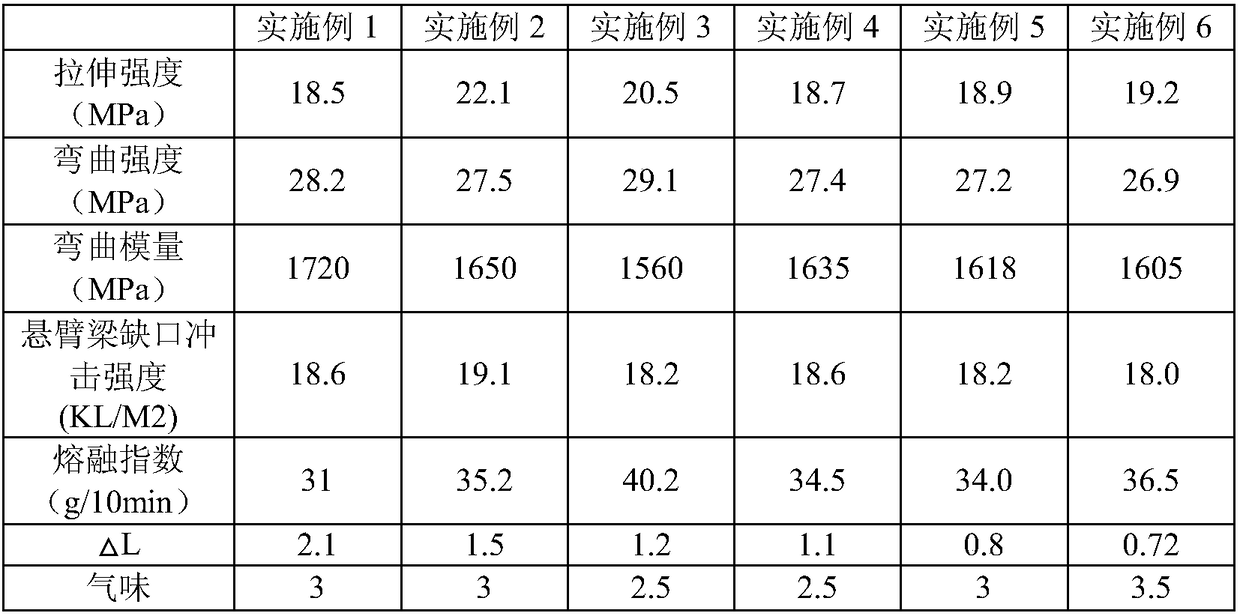

Examples

Embodiment 1

[0023] A method for preparing a spray-free scratch-resistant polypropylene material for automobiles, the steps are as follows:

[0024] (1) Weigh each component raw material according to the formula: 50 parts of high crystalline polypropylene (selected from Korea SK Chemicals, brand name PP-BX3900, melt flow rate 80g / 10min, flexural modulus 2000MPa); 22 parts of calcium carbonate; Toughening agent ethylene-octene copolymer (selected from Dow DuPont, brand ENGAGE-8150) 10 parts; scratch-resistant agent modified polysiloxane (selected from Zhejiang Jiahua, brand HG-600S) 1 part; aluminum 0.5 part of the pigment particle size range of 10-100 microns; 0.1 part of the nucleating agent methylene bis (2,4-di-tert-butylphenyl) aluminum phosphate (selected from Japan Asahi Denka, brand NA-21); coupling Agent alkyl modified polysiloxane (selected from boiling point chemical industry, brand FD-3301) 0.3 parts; light stabilizer is poly-{[6-[(1,1,3,3,-tetramethylbutyl) -amino]1,3,5,-triaz...

Embodiment 2

[0029] A method for preparing a spray-free scratch-resistant polypropylene material for automobiles, the steps are as follows:

[0030] (1) Weigh each component raw material according to the formula: 85 parts of high crystalline polypropylene (selected from Korea SK Chemicals, brand name PP-BX3900, melt flow rate 90g / 10min, flexural modulus 1920MPa); 10 parts of calcium carbonate; Toughening agent ethylene-octene copolymer (selected from Dow DuPont, brand ENGAGE-8150) 8 parts; scratch-resistant agent modified polysiloxane (selected from Zhejiang Jiahua, brand HG-600S) 2 parts; 2 parts of pigment particle size in the range of 10-100 microns; 0.5 parts of nucleating agent methylene bis(2,4-di-tert-butylphenyl)aluminum phosphate (selected from Japan Asahi Denka, brand NA-21); coupling Agent alkyl modified polysiloxane (selected from boiling point chemical industry, brand FD-3301) 0.5 parts; light stabilizer is poly-{[6-[(1,1,3,3,-tetramethylbutyl) -amino]1,3,5,-triazine-2,4-diyl...

Embodiment 3

[0035] A method for preparing a spray-free scratch-resistant polypropylene material for automobiles, the steps are as follows:

[0036](1) Weigh each component raw material according to the formula: 75 parts of high crystalline polypropylene (selected from Korea SK Chemicals, brand name PP-BX3900, melt flow rate 100g / 10min, flexural modulus 1800MPa); 15 parts of calcium carbonate; 5 parts of toughening agent ethylene-octene copolymer (selected from Dow DuPont, brand ENGAGE-8150); 4 parts of anti-scratch agent modified polysiloxane (selected from Zhejiang Jiahua, brand HG-600S); Pigment particle size range of 10-100 microns 1 part; nucleating agent methylene bis (2,4-di-tert-butylphenyl) aluminum phosphate (selected from Japan Asahi Denka, brand NA-21) 0.3 parts; coupling Agent alkyl modified polysiloxane (selected from boiling point chemical industry, brand FD-3301) 0.8 parts; light stabilizer is poly-{[6-[(1,1,3,3,-tetramethylbutyl) -amino]1,3,5,-triazine-2,4-diyl][(2,2,6,6-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com