Method and equipment for producing directional vertical taper pipe in motorcycle through cold extrusion

A technology of cold extrusion and motorcycle, applied in the direction of metal extrusion dies, metal extrusion mandrels, other household appliances, etc., can solve the problems of waste materials, irregular inner holes, uneven wall thickness, etc., and reach the range of material selection Wide, smooth inside and outside rules, a wide range of options for the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

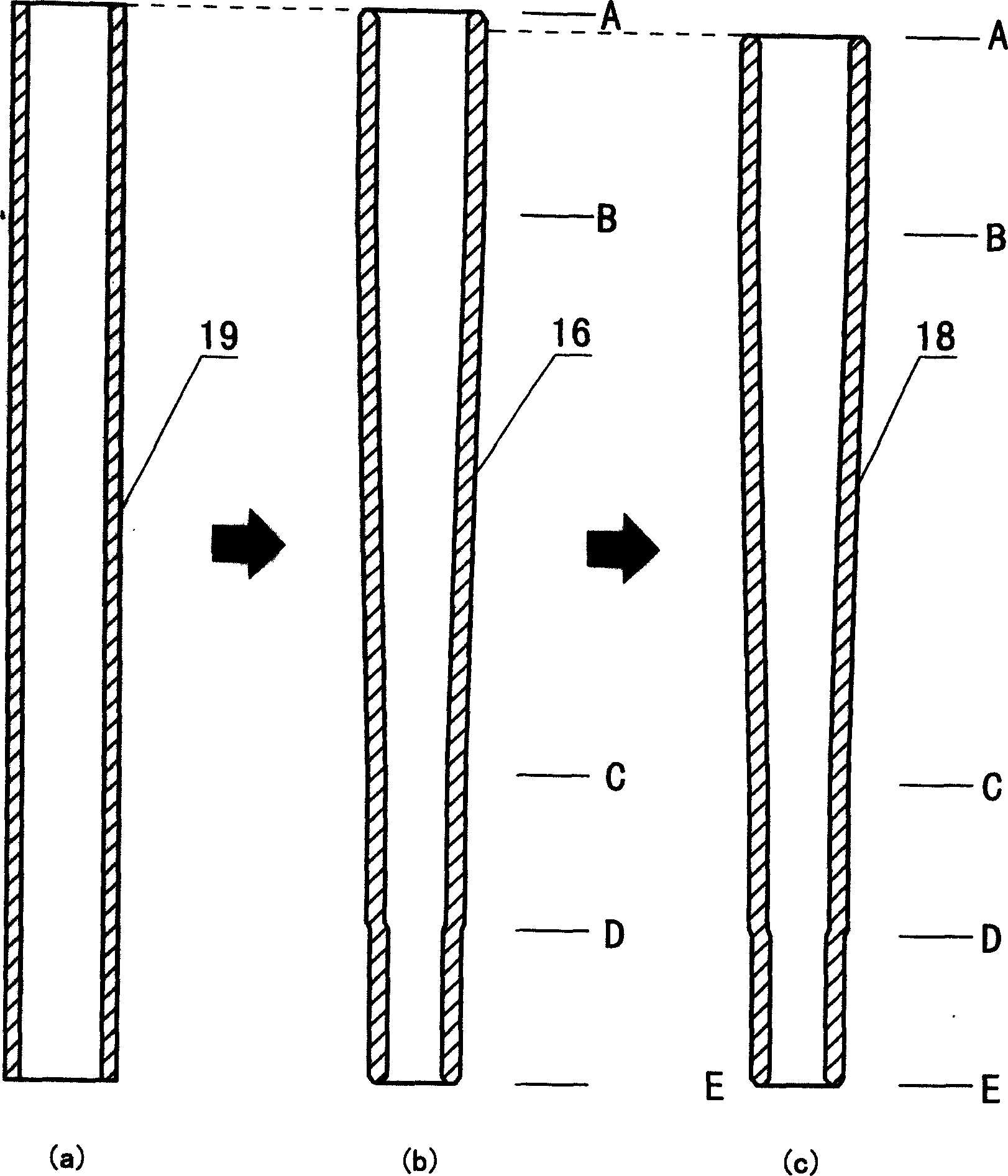

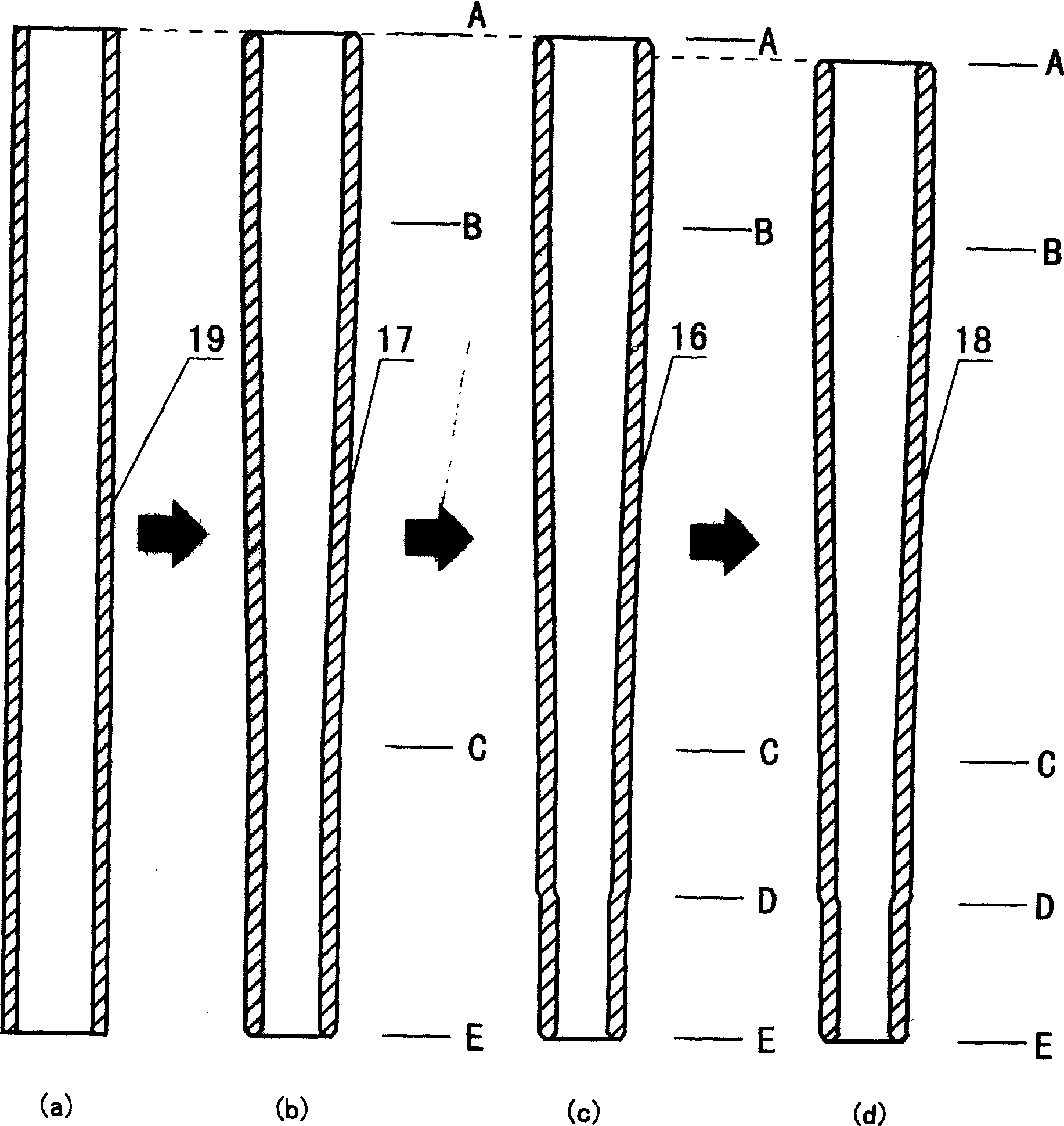

[0039] Such as figure 2 Shown, the steps of the present invention are as follows:

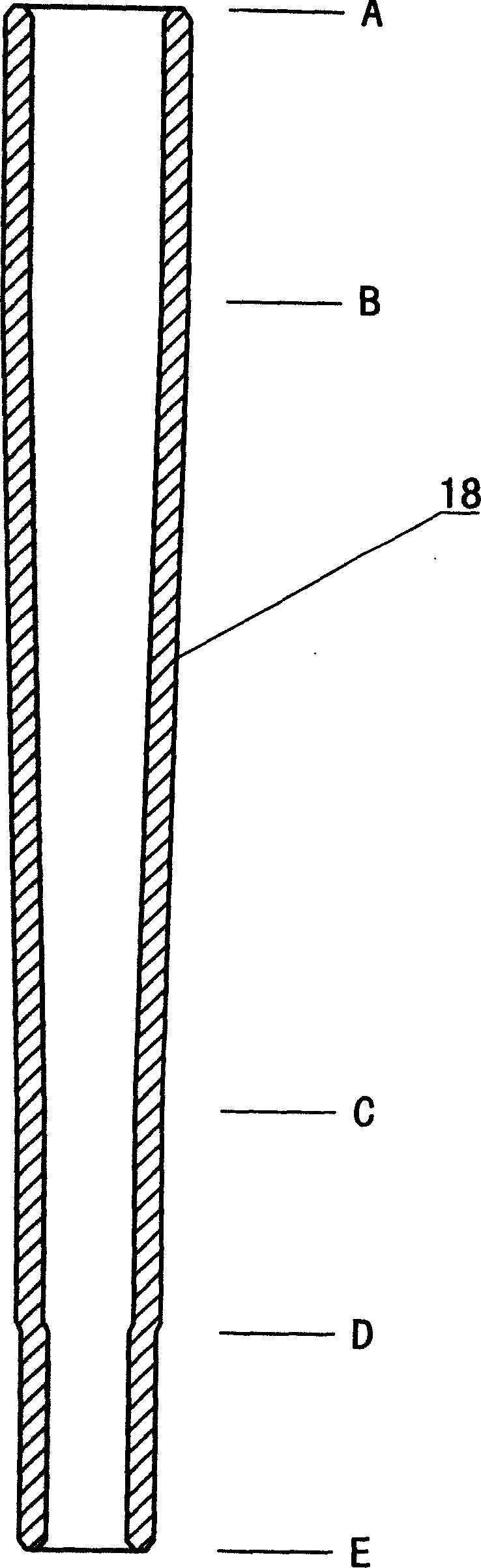

[0040] (1) Neck reaming: Under the cold extrusion of hydraulic equipment, the liquid pressure range is 10MPa ~ 35Mpa, the upper end of the inner diameter is small, the lower end is large, and the middle part is conical, the lower end is cylindrical, and the upper end is double. Cylindrical shrinkage dies with different diameters are placed on the steel pipe from the upper end of the steel pipe 19 coated with a release agent of equal diameter. The lower end is inserted into the steel pipe 19, so that the steel pipe 19 is preliminarily shaped into a conical standpipe 16 with a narrowed upper part and an enlarged lower part with a uniform and smooth outline based on the middle part, and then the hydraulic equipment is used for demoulding; figure 2 - In (b), segment AB is cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com