Low-fat high-protein yoghourt and preparation method thereof

A high-protein, low-fat milk technology, applied in the direction of milk preparations, dairy products, applications, etc., can solve the problems of powdery feeling (rough taste, yogurt flavor and texture influence, etc., achieve simple and easy processing methods, improve mutual Function, solve the serious effect of particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

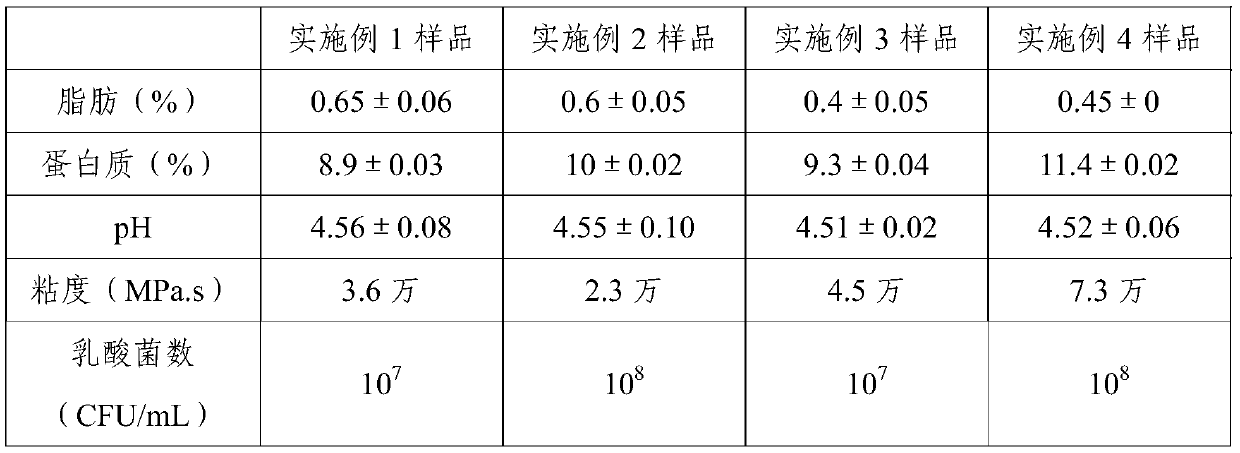

Embodiment 1

[0058] The preparation of embodiment 1 low-fat high-protein yogurt

[0059] Weigh 825ml of low-fat milk with a standardized protein content of 3% (somatic cells: 50,000 / mL, total bacteria: 30,000 CFU / mL), preheat to 55°C, add 8% white sugar (80g), milk protein concentrate 8 % is 80g (protein content is 61%), whey protein concentrate 1.5% is 15g (protein content is 82%). Set parameters of the high-shear mixer and high-shear emulsifier at 3000rpm, hold for 20min, homogenize at 15Mpa, 50°C, sterilize at 95°C for 300s, cool to 41°C and inoculate 0.15U of Lactobacillus bulgaricus and Streptococcus thermophilus , ferment at 39°C for 6h, break the emulsification at pH 4.56 for filling, and refrigerate at 2-6°C.

Embodiment 2

[0060] The preparation of embodiment 2 low-fat high-protein yogurt

[0061] Weigh 815ml of low-fat milk with a standardized protein content of 3% (somatic cells: 70,000 / mL, total bacteria: 35,000 CFU / mL), preheat to 55°C, add 8% white sugar (80g), milk protein concentrate 8 % is 80g (protein content is 61%), casein 1.5% is 15g (protein content is 82%), whey protein isolate is 1% or 10g (protein content is 90%). Set parameters of high-shear mixer and high-shear emulsifier to 4000rpm, hold for 20min, homogenize at 20Mpa, 50°C, sterilize at 95°C for 300s, cool to 37°C and inoculate 0.15U of Lactobacillus bulgaricus and Streptococcus thermophilus , Lactobacillus plantarum 0.025U, Lactobacillus casei 0.025U, fermented at 35°C for 7 hours, when the pH value was 4.55, the milk was broken for filling, and refrigerated at 2-6°C.

Embodiment 3

[0062] The preparation of embodiment 3 low-fat high-protein yogurt

[0063] Weigh 890ml of low-fat milk with a standardized protein content of 3% (somatic cells: 50,000 / mL, total bacteria: 30,000 CFU / mL), preheat to 60°C, add 2.5% white sugar (25g), sucralose 0.15 % is 0.15g, 2% skim milk powder is 20g (34% protein content), whey protein concentrate is 20g (82% protein content), and 4.5% casein is 45g (82% protein content). Set parameters of high-shear mixer and high-shear emulsifier at 3000rpm, hold for 15min, homogenize at 20Mpa, 55°C, sterilize at 95°C for 300s, cool to 39°C and inoculate 0.15U of Lactobacillus bulgaricus and Streptococcus thermophilus , ferment at 37°C for 6 hours, break the emulsification at pH 4.51 for filling, and refrigerate at 2-6°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com