Method for preparing peptide with high antioxidant activity by utilizing rice residue protein treated by superhigh pressure

A rice dregs protein, oxidation activity technology, applied in protein food processing, protein food ingredients, applications and other directions, can solve the problems of inability to protein enzymolysis, poor alkaline protease hydrolysis effect, and many impurities, etc., to achieve antioxidant activity improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Rice dregs pretreatment: grind 500g of rice dregs and pass through an 80-mesh sieve to obtain rice dregs powder;

[0031] (2) Extracting rice dregs protein: Mix the rice dregs powder obtained in step (1) with 4 L of water, adjust the pH value of the mixture to 12 with 1.0 mol / L sodium hydroxide solution, at a temperature of 40 °C and a rotation speed of 700 r / min , constant temperature stirring reaction for 4h, then centrifuged at 4000r / min for 15min, collected the supernatant, adjusted the pH value of the supernatant to 5.4 with 1.0mol / L hydrochloric acid solution, left for precipitation for 2h, centrifuged at 4000r / min for 15min, discarded the supernatant liquid, washed the precipitate with deionized water to neutrality, and the precipitate was rice dregs protein;

[0032] (3) Ultra-high pressure treatment: The rice dregs protein obtained in step (2) is packed in double-layer polyvinyl chloride bags, sealed, treated under 400MPa pressure for 10min, and lyophilized...

Embodiment 2

[0038] (1) Rice dregs pretreatment: grind 500g of rice dregs and pass through a 60-mesh sieve to obtain rice dregs powder;

[0039] (2) Extracting rice dregs protein: Mix the rice dregs powder obtained in step (1) with 3 L of water, adjust the pH value of the mixture to 11 with 1.0 mol / L sodium hydroxide solution, at a temperature of 30 °C and a rotation speed of 500 r / min , constant temperature stirring reaction for 3h, then centrifuged at 3000r / min for 10min, collected the supernatant, adjusted the pH value of the supernatant to 5.0 with 1.0mol / L hydrochloric acid solution, left to settle for 1h, centrifuged at 3000r / min for 10min, discarded the supernatant liquid, washed the precipitate with deionized water to neutrality, and the precipitate was rice dregs protein;

[0040] (3) Ultra-high pressure treatment: The rice dregs protein obtained in step (2) is packed in double-layer polyvinyl chloride bags, sealed, treated under 300MPa pressure for 5min, and freeze-dried under va...

Embodiment 3

[0046] (1) Rice dregs pretreatment: grind 500g of rice dregs and pass through a 100-mesh sieve to obtain rice dregs powder;

[0047] (2) Extracting rice dregs protein: Mix the rice dregs powder obtained in step (1) with 5 L of water, adjust the pH of the mixture to 13 with 1.0 mol / L sodium hydroxide solution, at a temperature of 50 ° C and a rotation speed of 900 r / min , constant temperature stirring reaction for 5h, then centrifuged at 5000r / min for 20min, collected the supernatant, adjusted the pH value of the supernatant to 5.8 with 1.0mol / L hydrochloric acid solution, left to settle for 3h, centrifuged at 5000r / min for 20min, discarded the supernatant liquid, washed the precipitate with deionized water to neutrality, and the precipitate was rice dregs protein;

[0048] (3) Ultra-high pressure treatment: The rice dregs protein obtained in step (2) was packed in double-layer polyvinyl chloride bags, sealed, treated under 500MPa pressure for 15min, and lyophilized under vacuu...

PUM

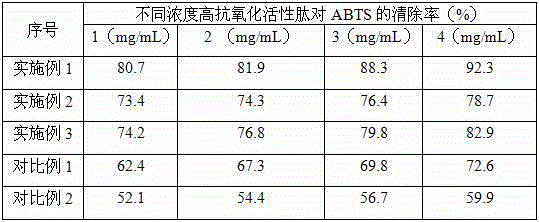

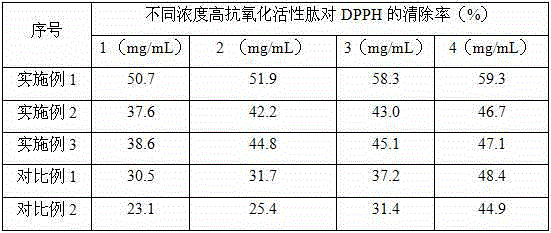

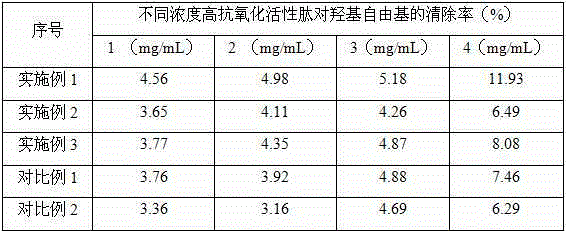

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com