Method for recycling water-soluble proteins in minced fish rinsing water

A technology for rinsing water and water-soluble protein in surimi is applied in the field of protein recovery, which can solve the problems of low protein recovery rate, small processing capacity, low protein recovery rate, etc., and achieves efficient recovery of water-soluble protein, improved sedimentation effect, and enhanced ionization. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Preparation of rinsing water for blue round surimi

[0027] 1. Buy blue trevally with good meat quality and bright color as raw material from the farmer’s market, rinse with clean ice water to remove the dirt and bacteria attached to the surface, then cut, remove the head, remove the internal organs, and perform a second time with water Wash, generally wash 2~3 times;

[0028] 2. Separate the fish meat from the fish body, stir slowly for 10 min with water at 3~10 °C, and let it stand. After rinsing for 2~3 times, use a centrifuge (Beckman, avanti-25) to dehydrate and collect The supernatant obtained by the above centrifugation is the surimi rinse water.

Embodiment 2

[0029] Example 2: Recovery of water-soluble protein in rinsing water of blue trevally

[0030] 1. Salt degreasing at low temperature: Weigh 300 g of table salt and slowly add 10L of blue trevally surimi rinsing water obtained in Example 1 (rinsing water protein concentration 90 g / L), and control the rinsing water temperature in the whole process below 10°C , Stir for 30 minutes, fully dissolve the salt, and let it stand for one hour to make the grease precipitate and float on the surface to remove the floating grease on the surface of the material liquid;

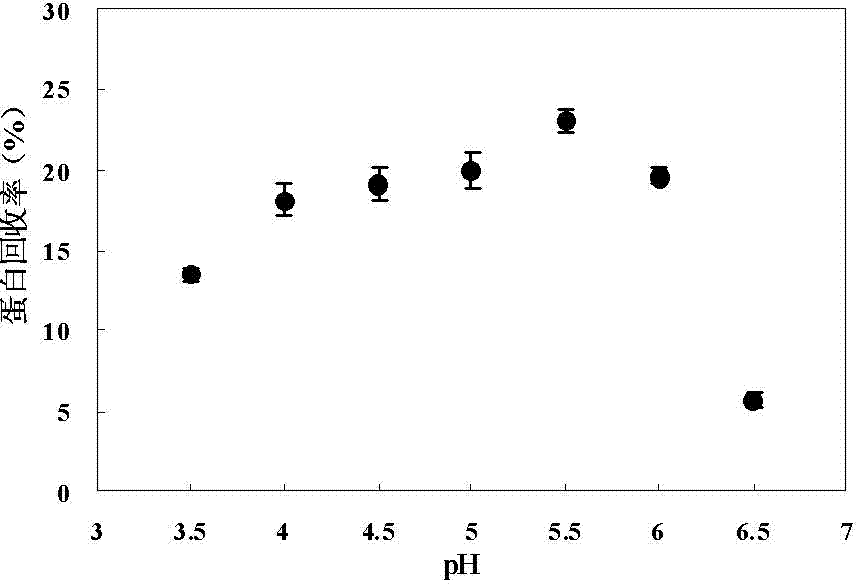

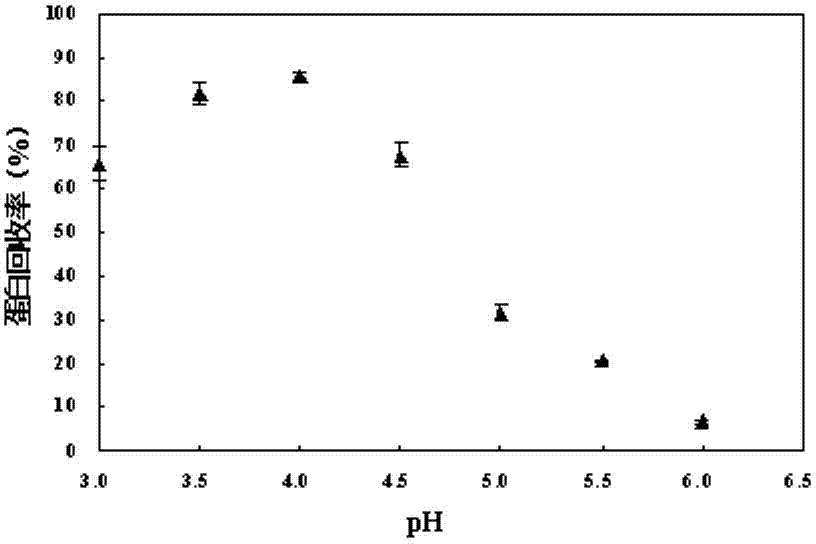

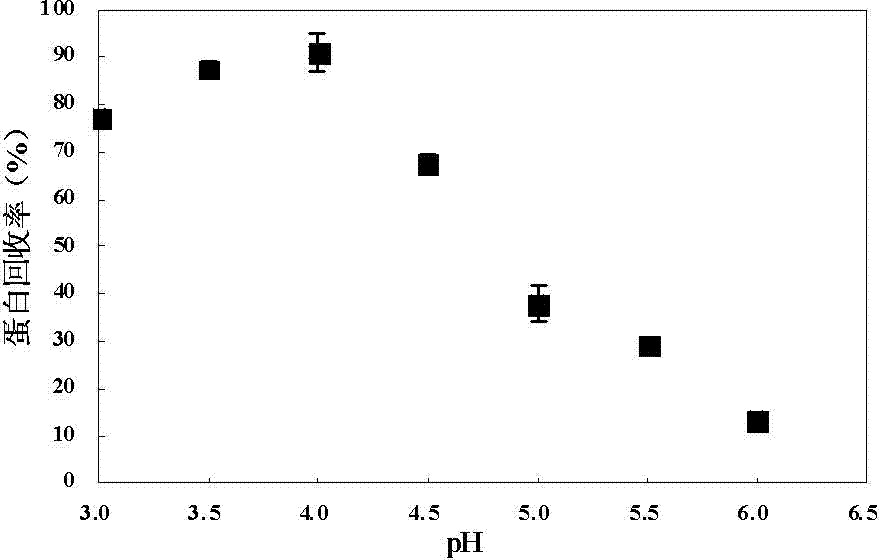

[0031] 2. Isoelectric point sedimentation of protein: add acid (5 mol / L HCl) to the obtained material solution until the pH of the solution reaches 4.0, and let it stand for three hours;

[0032] 3. Preliminary recovery of protein: remove the supernatant part of the obtained material liquid that has been layered, and collect the lower protein sedimentation layer;

[0033] 4. Recovering protein by centrifugation: Use a high-speed c...

Embodiment 3

[0036] Example 3: Recovery of water-soluble protein in rinsing water of blue trevally

[0037] 1. Salt degreasing at low temperature: weigh 90 g of table salt and slowly add 3 L of blue trevally surimi rinsing water (rinse water protein concentration 90 g / L), control the rinsing water temperature in the whole process below 10°C, and stir for 30 minutes , Fully dissolve the salt, let it stand for one hour to make the grease precipitate and float on the surface, and remove the floating grease on the surface of the material liquid;

[0038] 2. Isoelectric point sedimentation of protein: add acid to the obtained material liquid until the pH of the solution is 4.0, and let it stand for three hours;

[0039] 3. Preliminary recovery of protein: remove the supernatant part of the obtained material liquid that has been layered, and collect the lower protein sedimentation layer;

[0040] 4. Spray drying method to recover protein: the obtained protein material liquid is spray-dried into a prote...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com