Curing and forming die for preparing foamed ceramic according to protein foaming method and preparation method of curing and forming die

A technology of solidification molding and foam ceramics, which is applied in the direction of ceramic molding machines, ceramic products, household appliances, etc. It can solve the problems of blank body cracking, uneven product pore size distribution, uncontrollable slurry curing air pressure, etc., and achieve good formability, The effect of low cost and no pollution to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

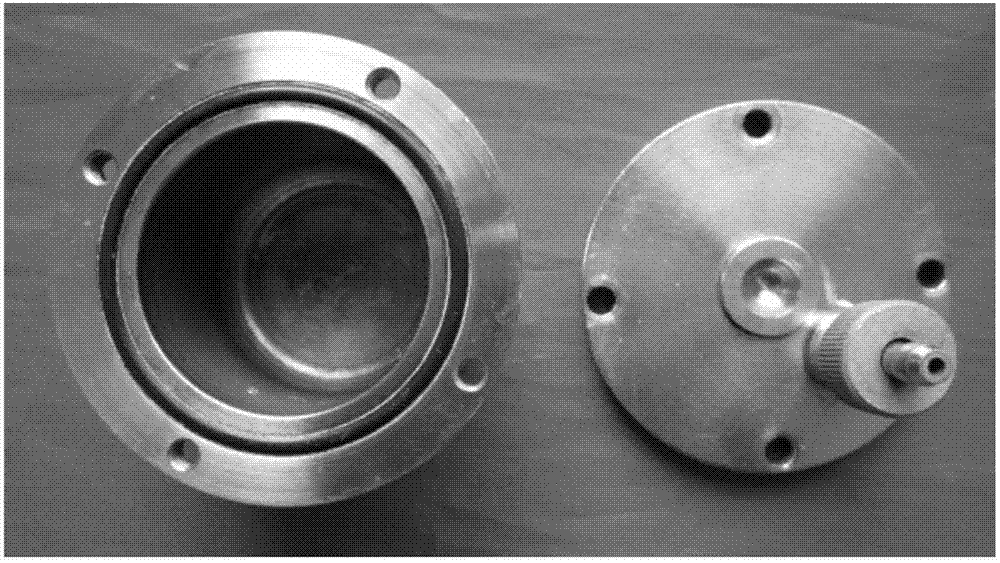

[0041] Example 1: Preparation of solidification molding molds for foam ceramics by protein foaming method.

[0042] a kind of like figure 1 , Figure 10 ~ Figure 14 The protein foaming method of the present invention is shown to prepare the curing molding mold for foam ceramics. The curing molding mold of this embodiment includes a mold body 1 and a mold cover 2. The mold body 1 and the mold cover 2 are hermetically connected to form a hollow mold cavity 4 , the mold cover 2 is provided with an air pressure control valve 3 (see Figure 13 ), the air pressure control valve 3 is provided with an air flow channel 5 connecting the mold cavity 4 and the outside world, and the opening and closing of the air pressure control valve 3 is regulated by the atmospheric pressure difference between the mold cavity 4 and the outside world. Such as Figure 14 As shown, the air pressure control principle in the mold is: during the curing molding process, as the curing temperature increase...

Embodiment 2

[0043] Embodiment 2: the method for preparing foamed ceramics by protein foaming method.

[0044] A kind of protein foaming method of the present invention prepares the method for silicon nitride ceramics, comprises the following steps:

[0045] (1) Preparation of foam slurry: mix and dissolve silicon nitride powder, sintering aids cerium oxide and alumina, and DURAMAX-D3005 dispersant produced by Rohm and Haas in water, and add silicon nitride powder to solvent water The amount is 40vol.%, the addition amount of sintering aid cerium oxide and aluminum oxide relative to the silicon nitride powder is 6wt% and 2wt%, respectively, the addition amount of D3005 dispersant relative to the solid phase component is 0.35wt.%, ball milling 20 Hour; Then add its 8wt.% egg white protein powder to the mixed component after ball milling, obtain foam slurry after ball milling for 2 hours;

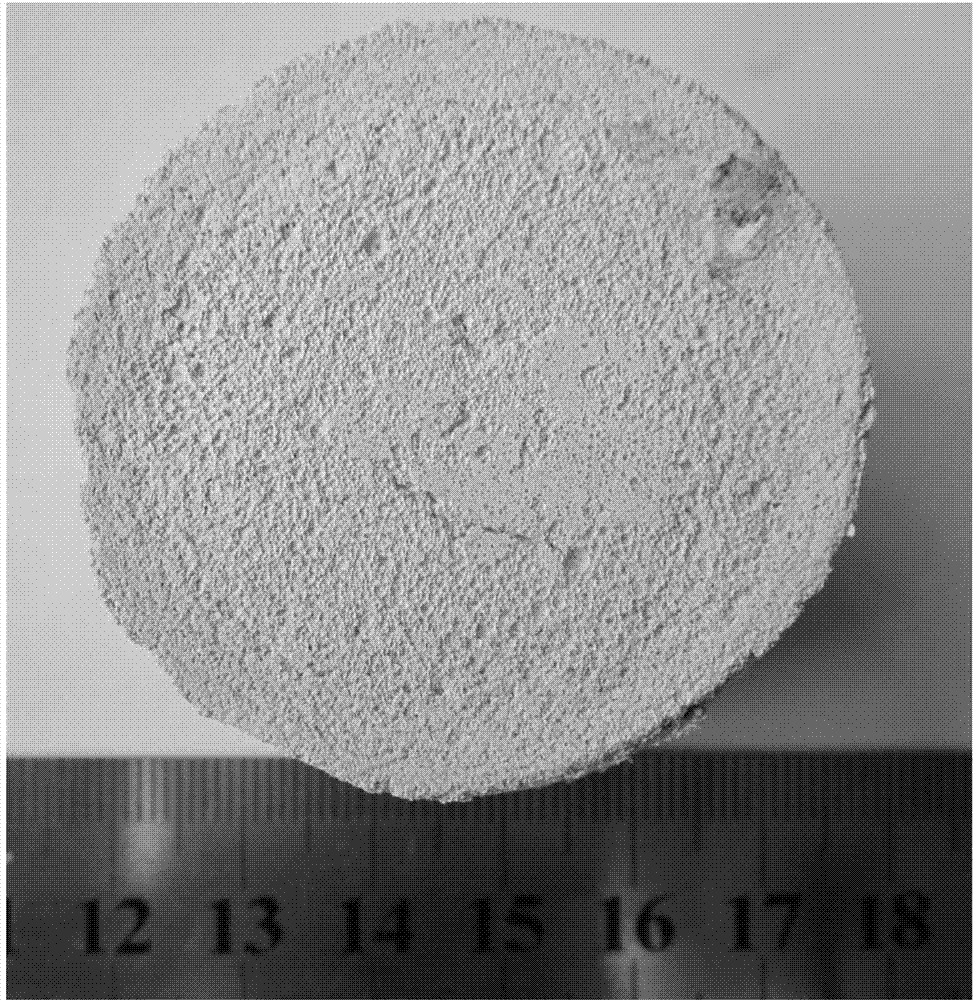

[0046] (2) Curing molding: inject the obtained foam slurry into an open molding mold (the mold is o...

Embodiment 3

[0052] A kind of protein foaming method of the present invention prepares the method for silicon nitride ceramics, comprises the following steps:

[0053] (1) Preparation of foam slurry: mix and dissolve silicon nitride powder, sintering aids cerium oxide and alumina, and DURAMAX-D3005 dispersant produced by Rohm and Haas in water, and add silicon nitride powder to solvent water The amount is 40vol.%, the addition amount of sintering aid cerium oxide and aluminum oxide relative to the silicon nitride powder is 6wt% and 2wt%, respectively, the addition amount of D3005 dispersant relative to the solid phase component is 0.35wt.%, ball milling 20 Hour; Then add its 8 wt.% egg white protein powder to the mixed component after ball milling, obtain foam slurry after ball milling for 2 hours;

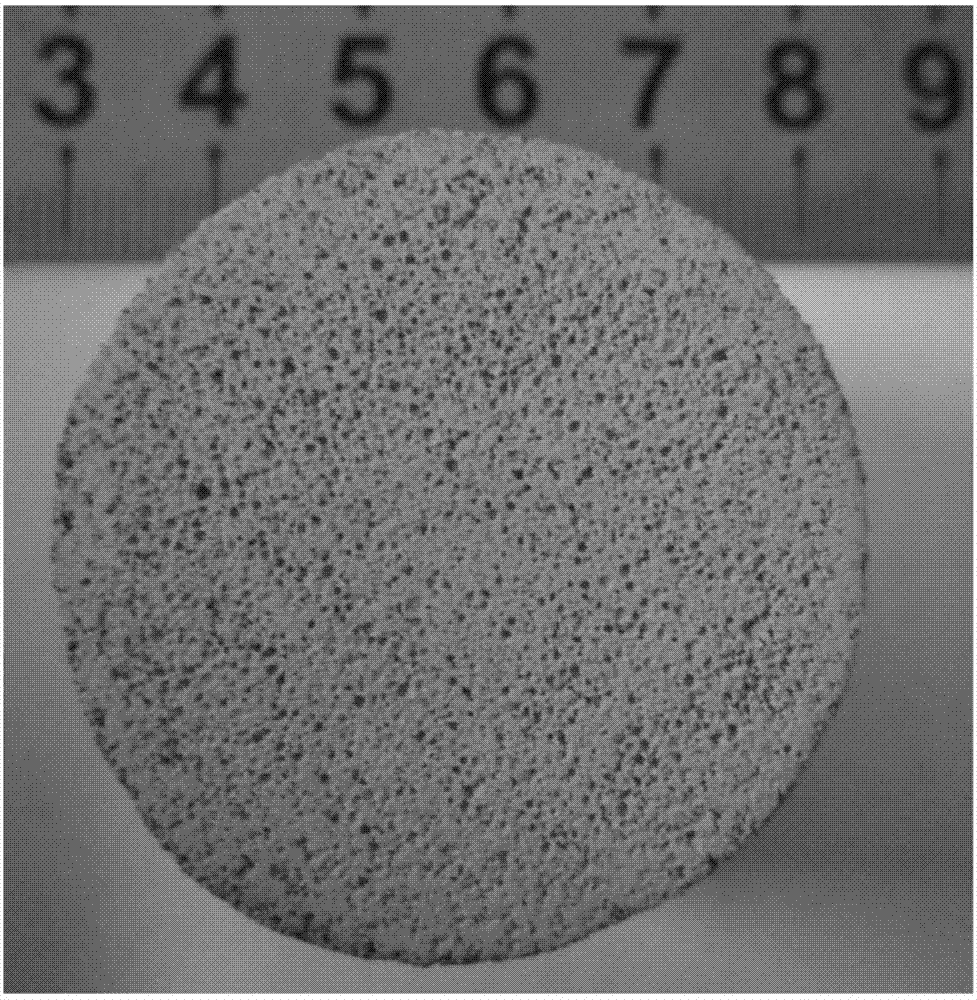

[0054] (2) Curing molding: inject the obtained foam slurry into a completely closed mold (the mold is completely sealed, and the curing molding pressure is continuously increased), and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com