Grease hydrogenation catalyst

A technology of fat hydrogenation and catalyst, which is applied in the direction of physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, fatty acid hydrogenation, etc., can solve the problem of accelerating oil and other problems, and achieve the increase of sliding melting point and the source of raw materials Rich, active metal-stabilized effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Catalyst preparation conditions:

[0026] (1) Carrier ZrO 2 Preparation of zirconyl nitrate solid into an aqueous solution, and gradually add ammonia solution (1 mol / L) until a precipitate occurs. It was centrifuged and washed until neutral. The obtained solid was dried at 110 °C, and finally baked in a muffle furnace at 550 °C for 5 h;

[0027] (2) Weigh 160000 μg of solid chloroplatinic acid hexahydrate, dissolve it in distilled water and add 3 g of zirconia carrier to make 2%Pt / ZrO 2 (The weight of the carrier is the benchmark). The actual platinum loading determined by ICP-AES was 1.79% Pt / ZrO 2 (The weight of the carrier is the benchmark);

[0028] (3) Stir the chloroplatinic acid solution and the zirconia carrier continuously at room temperature for 16 h, stir evenly and evaporate to dryness in a rotary evaporator under reduced pressure;

[0029] (4) Transfer the synthesized solid to a watch glass and dry it under vacuum at 60 °C. Then bake in a muffle furn...

Embodiment 2

[0032] Catalyst effect experiment of the present invention:

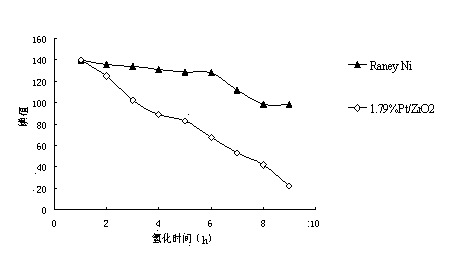

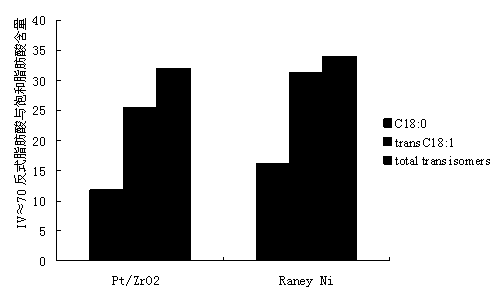

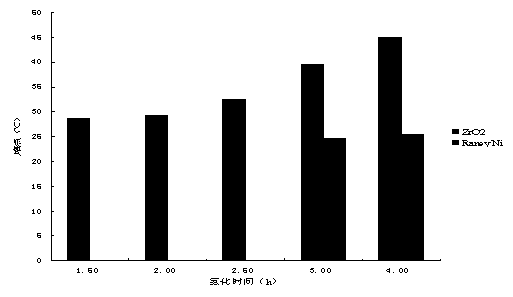

[0033] Hydrogenation process conditions: Measure 300 mL of soybean oil, weigh 150 mg of the catalyst prepared in Example 1 (to ensure that the amount of catalyst is 5%, based on the weight of the raw oil), pour them into the hydrogenation reactor together Seal it well and start preheating to 170°C. Introduce nitrogen to exhaust the air for 2-4 minutes, continue to replace nitrogen with high-purity hydrogen for 3-5 minutes, then keep the hydrogen pressure at 3 bar, start the stirring device to maintain the speed at 400 r / min, and record the hydrogenation time at this time as 0 h. Afterwards, samples were taken every 0.5 h, and the co-hydrogenation reaction was carried out for 4 h. The iodine value of the hydrogenated oil samples was determined, and each sample was analyzed by gas phase detection. figure 2 The content of trans-fatty acid when the iodine value is 70-90 is counted in , and the data shows that 1.79%Pt / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com