Method for processing sesame oil and protein food at low temperature

A technology of sesame and protein, applied in the field of manufacturing edible oil and protein food, can solve the problem of low utilization rate of sesame, and achieve the effects of pure and rich aroma, low temperature, and complete separation of oil and fat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

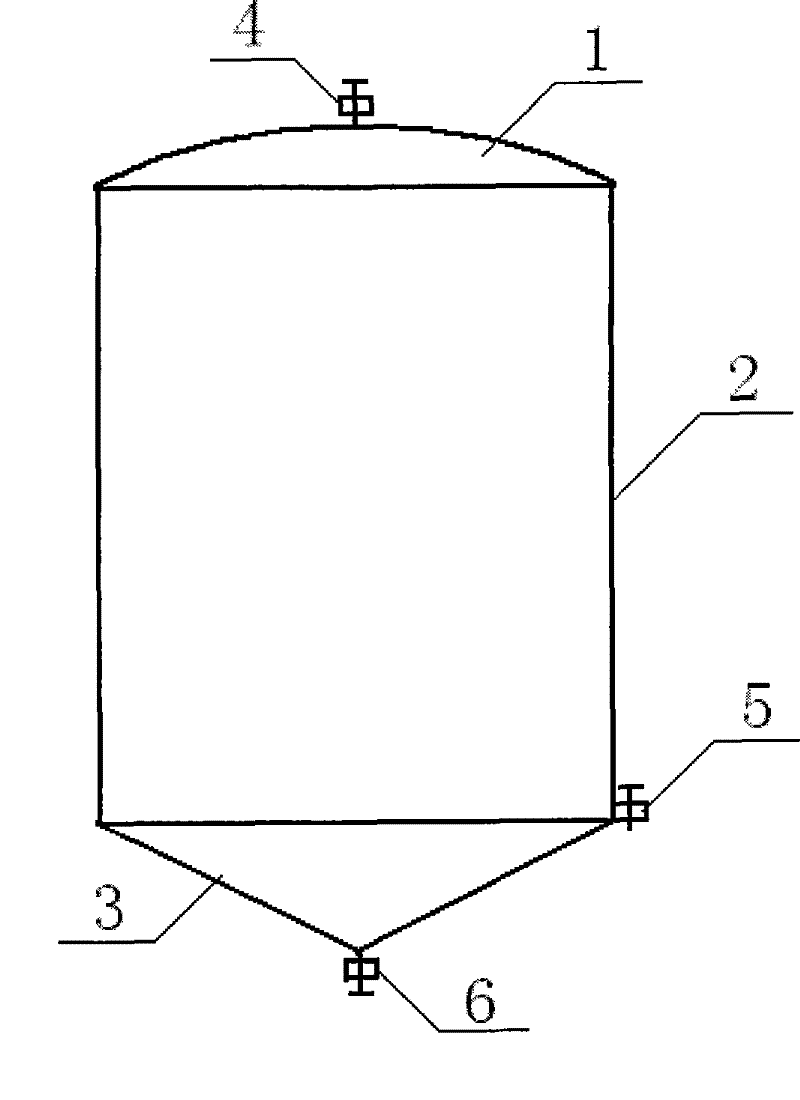

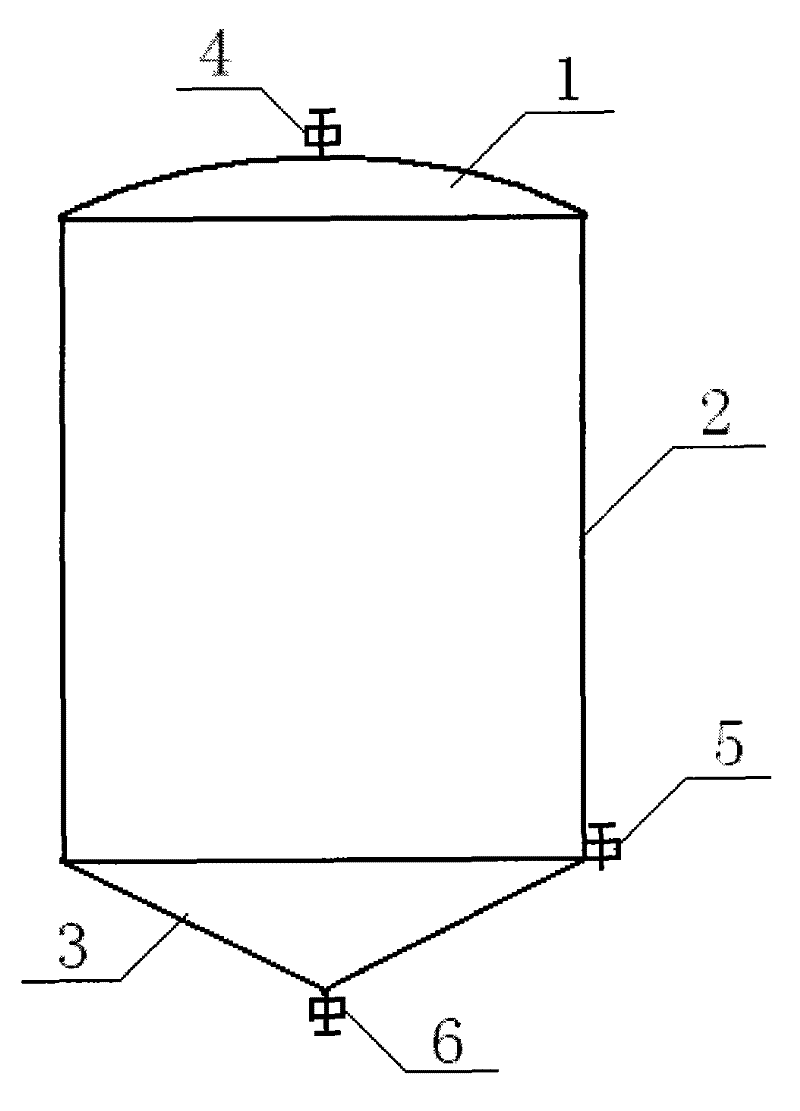

Image

Examples

Embodiment 1

[0025]Embodiment 1: The manufacture method of low-acid and low-impurity sesame oil, the following steps are carried out in sequence: A, cleaning, choose 100 kilograms of sesame seeds, add clear water to soak, and remove corrupt sesame seeds and seedlings during cleaning; B, peeling, After the cleaned sesame is placed for 9 minutes, it is peeled. During peeling, a peeling machine can be used; After 27 minutes, the sesame can be dried; D, take the oil, grind the dried sesame into a fine slurry with a mill (preferably a traditional stone mill), and the fine slurry can reach a particle size of less than 250 microns (also can be less than 60 mesh) ); 90-95 kilograms of sesame fine slurry formed at this moment, take by weighing 90 kilograms of purified water, the purified water is heated to 65 ℃, scald with purified water to get the oil, after 21 hours, realize the oil slurry separation, can form grease 35 ~38 kg, the lower part is precipitated into protein slurry 142~150 kg; E, ref...

Embodiment 2

[0026] Embodiment 2: the manufacture method of low-acid and low-impurity sesame oil, carry out the steps identical with embodiment 1 in sequence, process condition is done certain adjustment: A, cleaning; B, peeling, the sesame seed placement time is changed into 11 minutes; C, Sun-dried, heat the general boiler (fire heating) to 75°C, and dry the sesame seeds for 23 minutes; D, take the oil, grind the dried sesame seeds into a fine pulp, and the fine pulp reaches a particle size of less than 180 microns (It can also be less than 100 meshes); take purified water, heat the purified water to 75°C, scald with purified water to get the oil, after 19 hours, realize the separation of the oil slurry, and the lower part is precipitated into a protein solution; E, refining, put Put the oil into the deoxidation tank, control the temperature at 11°C, keep it for 48 hours, then adjust the temperature to -4°C, keep it for 24 hours; repeat 8 times; it is the finished product, which can be so...

Embodiment 3

[0036] Embodiment 3: the manufacturing method of sesame protein beverage is as follows:

[0037] According to the operation described in embodiment 1 or 2, promptly carry out A, cleaning; B, dehulling; C, dry; Homogenization, packaging, sterilization, and the process conditions of each process of the finished product are carried out according to the processing conditions of conventional soy milk beverages (such as peanut milk, soy milk, etc.). Among them: Grinding, the slurry after oil extraction is cooled and put into the colloid mill for rough grinding and fine grinding, the slurry after grinding reaches a particle size of 5 microns; Filtration, use a centrifuge or filter cloth to separate the juice from the slag, and take the juice; ingredients , add 0.3% (referring to the percentage of weight in sesame slurry, the same below) salt or add 3% sugar (usually select sucrose) to form a simple sesame protein drink; concentrate, that is, evaporate a certain amount of sesame prote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com