Starch/carboxylated polymer composites

a technology of carboxylated polymer and starch, which is applied in the field of starch/carboxylated polymer composites, can solve the problems of inability to fully absorb starch, rapid breakdown of initial high viscosity, and inability to withstand high temperature and humidity,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of a Starch / Carboxylated Polymer Composite

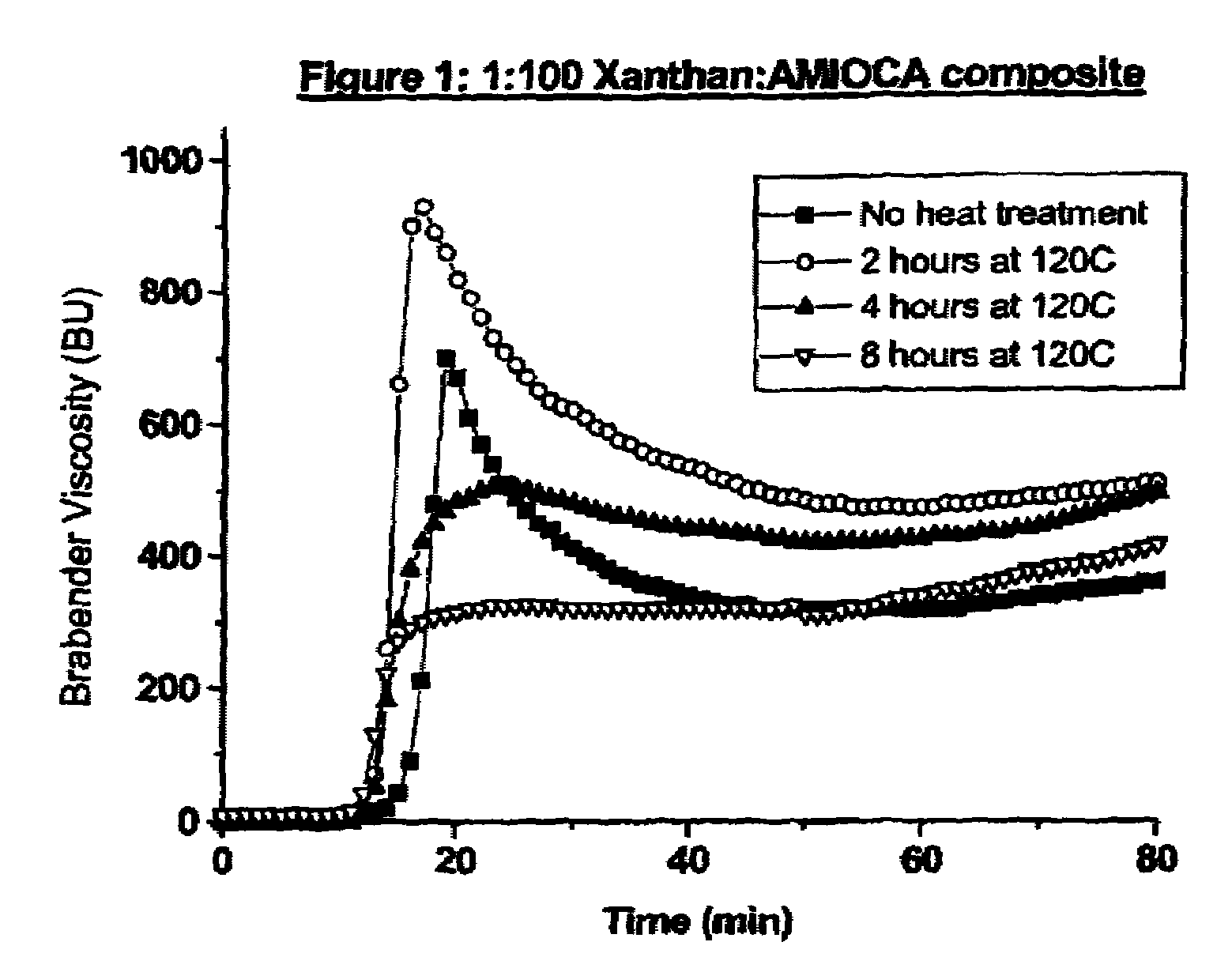

[0048]A 1:100 xanthan:waxy corn starch composite was prepared by air drying, followed by heat treatment in a pre-heated oven according to the following procedure.

[0049]Xanthan (25 g) was added to 2.5 liters of de-ionized water and the mixture stirred using a mechanical paddle (Baldor Electric Co., Electric Lab Stirrer with a strade blade impeller) for more than 1 hour, until the solution is fully hydrated. Starch powder (1666 g) was added to the 1% xanthan solution and the slurry stirred for 1 hour in a Ross Mixer. Additional starch (834 g) was added and stirred for a further 1 hour in the Ross Mixer. The mixture was then air-dried until the resultant powder had less than 20% moisture content (moisture level measured using a CSC Scientific Digital Moisture Balance). The powder was ground and filtered through a 60 mesh size screen.

example 2

Effect of Carboxylated Polymer:Starch Ratio.

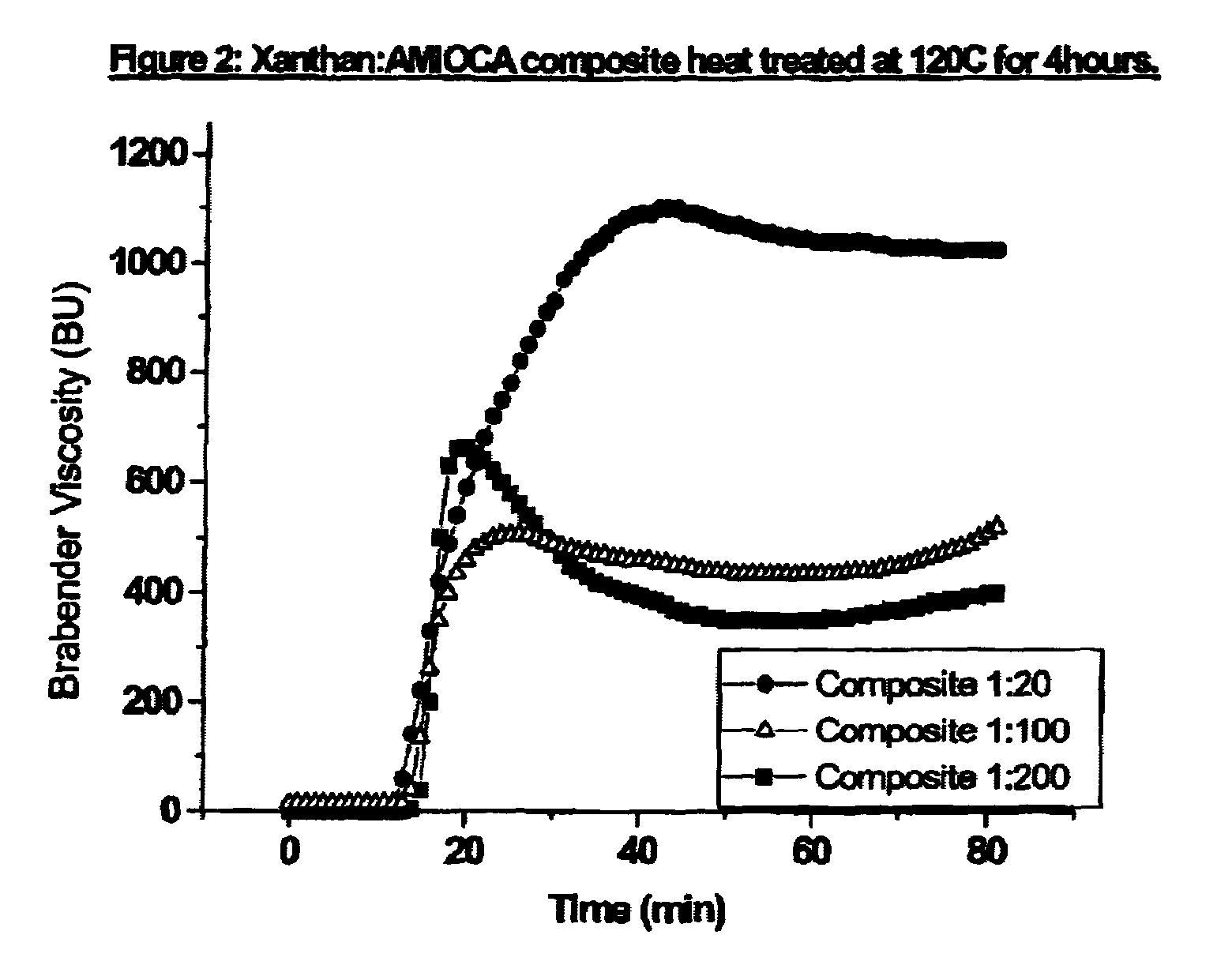

[0050]Xanthan:waxy corn starch (1:20, 1:100 and 1:200) composites were prepared according to the procedure detailed in Example 1, varying only the relative amount of xanthan and starch used for each sample. The level of inhibition for each sample was then measured according to Procedure A.

[0051]As is shown by FIG. 2, samples containing higher levels of xanthan showed progressively greater degrees of inhibition.

example 3

Effect of Types of Carboxylated Polymer upon the Composite

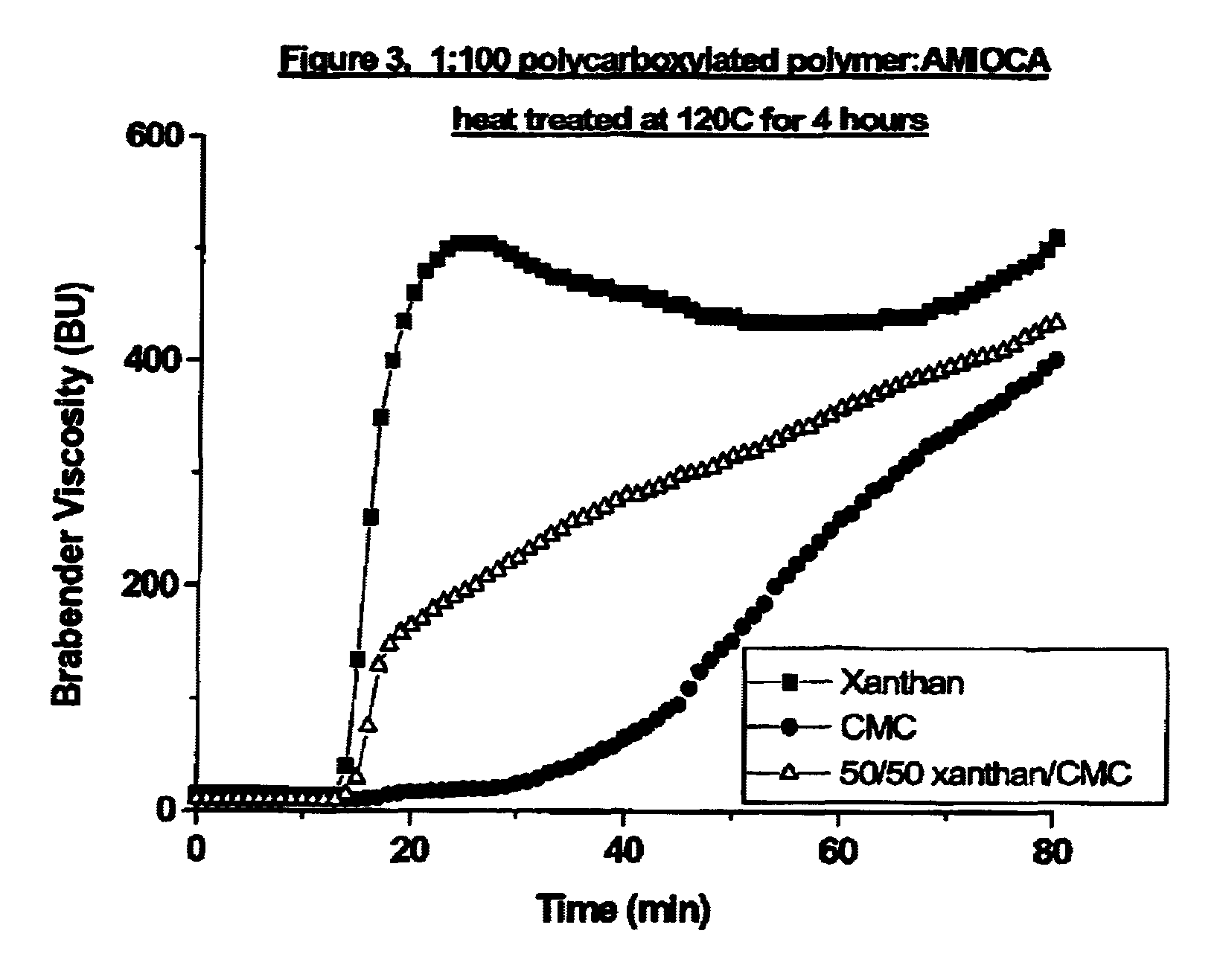

[0052]Three samples of 1:100 carboxylated polymer:starch composites were prepared as described in Example 1. In one sample, the polycarboxylated polymer was xanthan, in the second, carboxymethylcellulose and in the third, a 50:50 combination of xanthan and carboxymethylcellulose. Each composite was heat treated for 4 hours at 120° C.

[0053]Composites made with different polycarboxylated polymers had different viscosity profiles. For example, as FIG. 3 demonstrates, unlike the composites containing xanthan, the carboxymethylcellulose composite possessed a delayed viscosity increase.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com