Modification method for improving slow digestion performance of starch

A slow-digesting, starch technology, applied in fermentation and other directions, can solve the problems of single starch branching enzyme modification treatment conditions and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

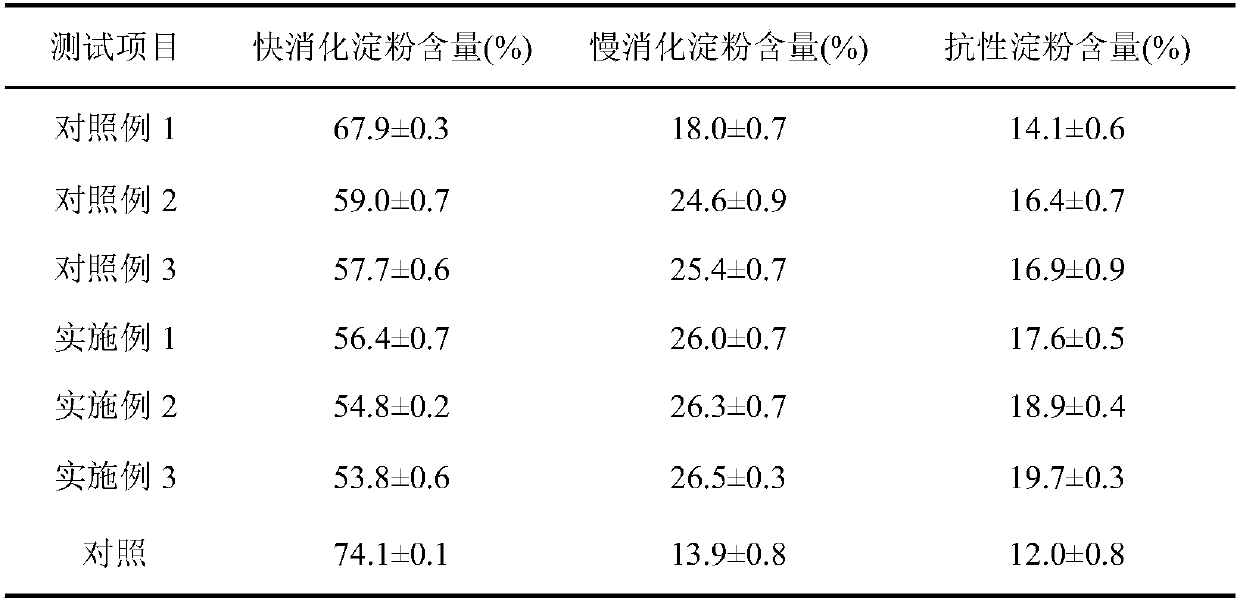

[0037] Example 1: Effect of Two-stage Modification on Slowly Digestible Starch Content in Starch

[0038] Dissolve cornstarch in water to prepare 5% starch milk, preheat at 50°C for 10min, add 30U / g starch branching enzyme, treat at 50°C for 10h, gelatinize in boiling water bath for 30min, preheat at 50°C for 10min Finally, add 30 U / g starch branching enzyme, treat at 50°C for 6 hours, stop the reaction in a boiling water bath, and freeze-dry to obtain modified starch. The results of the modified starch digestibility test are shown in Table 1.

[0039] The results of the reaction show that the two-stage modification with granular cornstarch and gelatinized cornstarch as substrates respectively, the content of slow-digestible starch in the prepared modified starch reaches 26.0%, which is 87.0% higher than that of the control. Example 3 (gelatinized cornstarch as substrate) further increased by 2.4%; fast digestible starch content increased by 23.9% compared to control example ...

Embodiment 2

[0040] Example 2: Effect of two-stage modification on slow-digestible starch content in starch

[0041]Dissolve cornstarch in water to prepare 5% starch milk, preheat at 50°C for 10min, add 30U / g starch branching enzyme, treat at 50°C for 10h, gelatinize in boiling water bath for 30min, preheat at 50°C for 10min Finally, add 30 U / g starch branching enzyme, treat at 50°C for 8 hours, stop the reaction in a boiling water bath, and freeze-dry to obtain modified starch. The results of the modified starch digestibility test are shown in Table 1.

[0042] The results of the reaction showed that cornstarch was modified using a two-stage modification strategy, and the content of fast-digestible starch in the prepared modified starch reached 54.8%, which was further reduced by 5.0% compared with the control example 3 (gelatinized cornstarch was the substrate). %; Slowly digestible starch content reaches 26.3%, which is further increased by 3.5% compared with control example 3 (gelatin...

Embodiment 3

[0043] Example 3: Effect of Two-stage Modification on Slowly Digestible Starch Content in Starch

[0044] Dissolve cornstarch in water to prepare 5% starch milk, preheat at 50°C for 10min, add 30U / g starch branching enzyme, treat at 50°C for 10h, gelatinize in boiling water bath for 30min, preheat at 50°C for 10min Finally, add 30 U / g starch branching enzyme, treat at 50° C. for 10 h, stop the reaction in a boiling water bath, and freeze-dry to obtain modified starch. The results of the modified starch digestibility test are shown in Table 1.

[0045] The results of the reaction show that cornstarch was modified using a two-stage modification strategy, and the content of fast-digestible starch in the prepared modified starch reached 53.8%, which was further reduced by 6.8% compared with the control example 3 (gelatinized cornstarch was the substrate). %; Slowly digestible starch content reaches 26.5%, further increased by 4.3% compared with control example 3 (gelatinized corn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com