Method for increasing contents of slowly digestible starch and resistant starch in starch

A technology of anti-digestive starch and slow-digesting starch, which is applied in the processing of dough, the function of food ingredients, baked goods, etc., can solve the problems of low efficiency, increased production cost, long processing time, etc., to reduce digestion rate and control body weight. , the effect of increasing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

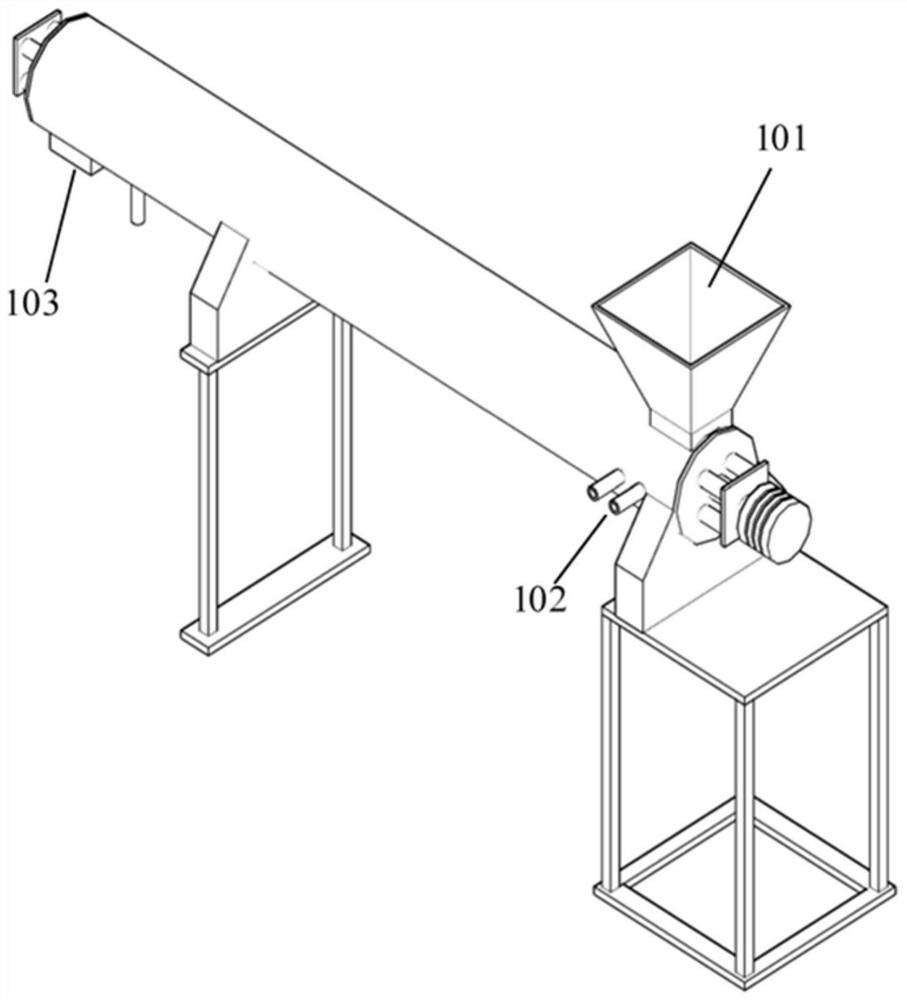

[0022] Example 1: Preparation of modified starch through wetting treatment and specific crushing treatment

[0023] Wet the cornstarch: Spray about 3.0kg of water on 20kg of cornstarch, leave it overnight to make the moisture content of cornstarch 25%; Connected with starch, the rate of superheated steam is 40kg / h. After the corn starch was heat-treated for 10 minutes, it was cooled to room temperature, and the sample was crushed with a DF series desktop continuous feeding pulverizer. The specific process was to place the sample in the feeding hopper continuously at a feeding speed of 30kg / h, and the sample was then After entering the crushing chamber, the sample is crushed under the impact of the 2850r / min high-speed motor-driven milling, and then the sample enters the collector through the shielding sieve, and then passes the sample through a 100-mesh vibrating sieve to obtain modified corn starch.

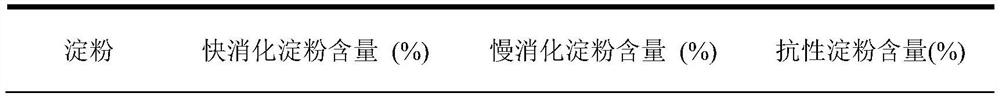

[0024] Fast digestible starch, slow digestible starch and resistant starch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com