Slowly digestible oat protein and preparation method thereof

An oat protein, slow digestion technology, applied in the field of nutrition and health, can solve rare problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

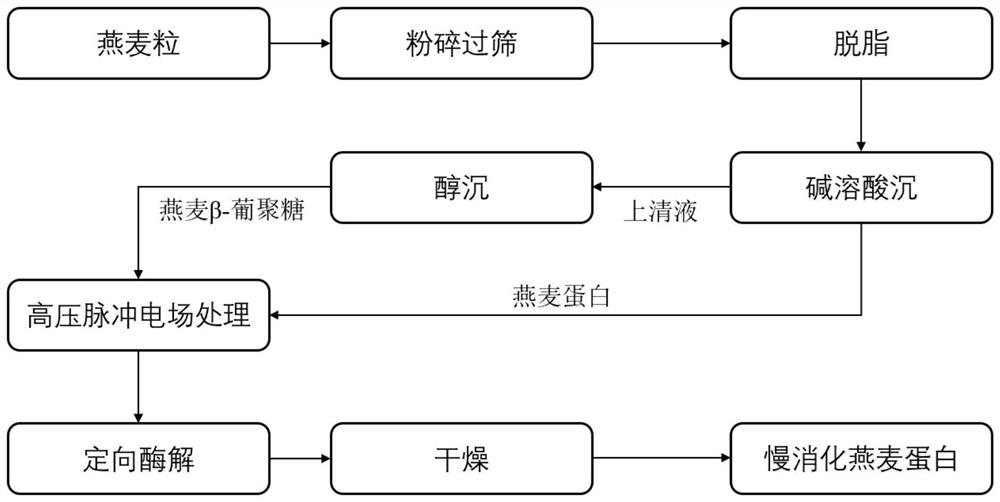

[0033] The second is a method for preparing slow-digesting oat protein. The slow-digesting oat protein is prepared by high-voltage pulsed electric field treatment and pepsin-directed enzymatic hydrolysis. The specific scheme is as follows:

[0034] (1) After mixing the oat protein and oat β-glucan obtained by the above method, disperse in water, and then use high-voltage pulsed electric field to treat it;

[0035] (2) Extract part of the easily digestible protein in the solution obtained in step (1) by pepsin-directed enzymatic removal, adjust the pH, centrifuge, and finally dry the obtained precipitate to obtain slow-digestible oat protein.

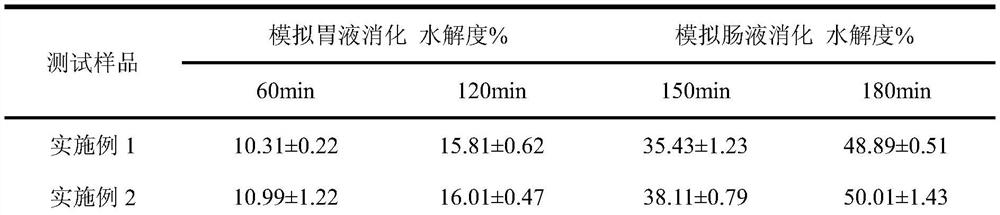

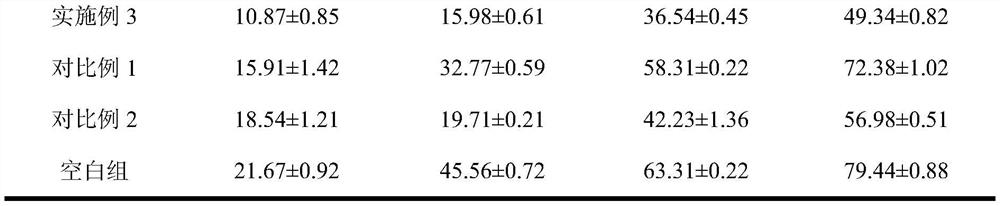

Embodiment 1

[0039] A slow-digesting oat protein and a preparation method thereof. Specific steps are as follows:

[0040] (1) Crumble oat grains through a 60-mesh sieve, disperse 500 parts of oat flour in 5000 parts of deionized water, add 50 parts of lipase, stir and degrease to obtain an enzymatic hydrolysis solution.

[0041] (2) Adjust the pH of the enzymatic solution obtained in step (1) to 10, stir and extract for 4 hours, centrifuge (5000g, 15min) to remove the precipitate, adjust the pH of the supernatant to 5.5, centrifuge (12000g, 15min) to collect the precipitate, and dry it Instant oat protein.

[0042] (3) Take 2000 parts of the supernatant after extracting oat protein in step (2), and adjust its pH to 7, add 8000 parts of ethanol to it, let it stand for 4h, centrifuge (12000g, 15min) to get the precipitate, and remove it Dried to get oat β-glucan.

[0043] (4) Take 50 parts of oat protein and 5 parts of oat β-glucan obtained in the above steps and mix them uniformly and d...

Embodiment 2

[0046] A slow-digesting oat protein and a preparation method thereof. Specific steps are as follows:

[0047] (1) Crush oat grains through a 60-mesh sieve, disperse 600 parts of oat flour in 3000 parts of deionized water, add 18 parts of lipase, and stir to degrease.

[0048] (2) Adjust the pH of the enzymolysis solution obtained in step (1) to 8, stir and extract for 2 hours, centrifuge (3000g, 10min) to remove the precipitate, adjust the pH of the supernatant to 4.5, centrifuge (8000g, 10min) to collect the precipitate, and dry it Instant oat protein.

[0049] (3) Take 1500 parts of the supernatant after extracting oat protein in step (2), and adjust its pH to 7, add 3000 parts of ethanol to it, let stand for 2h, centrifuge (8000g, 10min) to get the precipitate, and Dried to get oat β-glucan.

[0050] (4) Take 100 parts of oat protein and 1 part of oat β-glucan obtained in the above steps and mix them uniformly and disperse them in 303 parts of deionized water. It is proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com