A preparation method of brown rice noodle with improved steaming and eating quality

A technology of brown rice and rice noodles, which is applied in the field of preparation of brown rice noodles, which can solve the problems of low quality of brown rice noodles, rough taste of brown rice noodles, low cooking loss rate, etc., and achieve the expansion of product production and sales channels, low firmness and low shear power , The effect of reducing the breaking rate and loss rate of cooking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

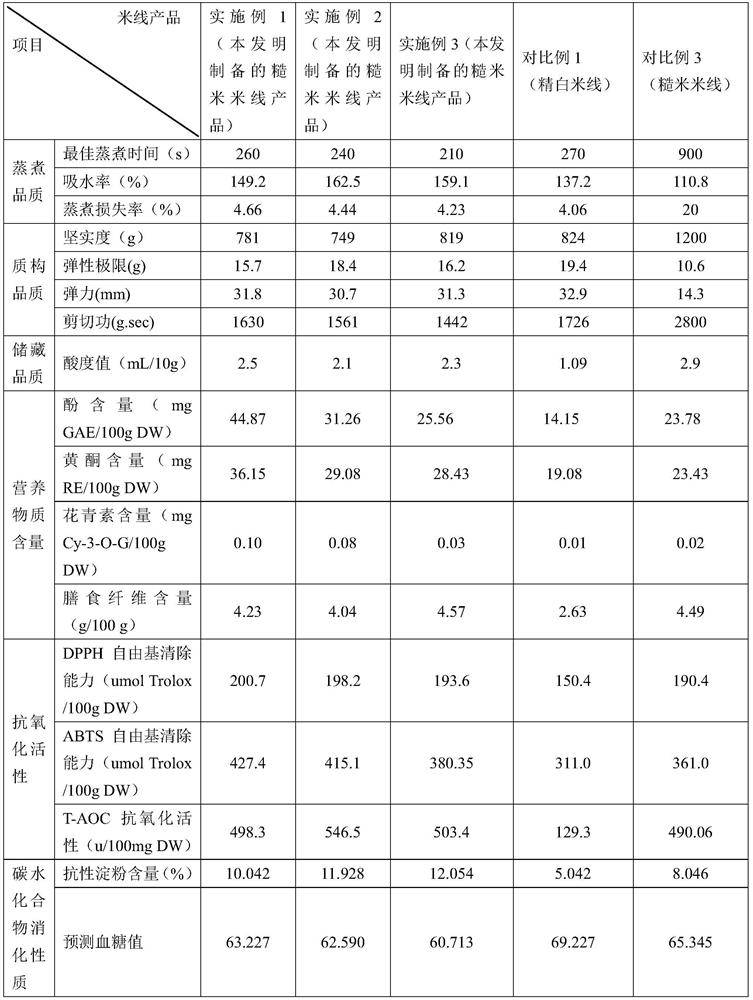

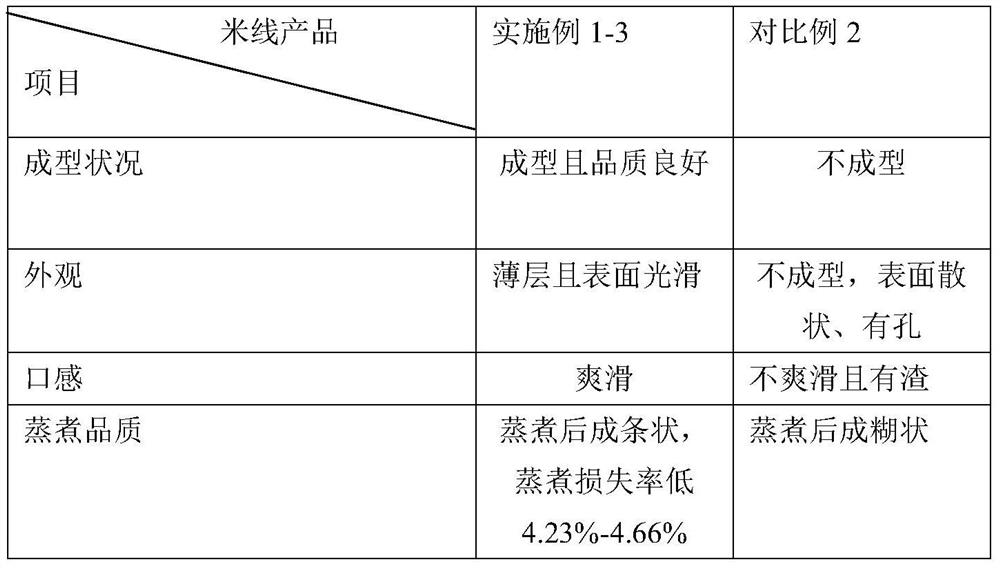

Examples

Embodiment 1

[0037] Select indica brown rice, remove floating ash and mixed gravel and other sundries, wash with pure water, and grind to obtain rice bran and white rice. The method of twin-screw extrusion is adopted, the moisture content of the material is adjusted to 15%, and the rice bran is extruded under the conditions of a temperature of 100° C. and a screw speed of 200 r / min. After the rice bran is cooled, soak the rice bran and water at a ratio of 1:2 for 2 hours, and use a colloid mill to grind the rice bran to control the particle size range of 200-300 μm. Soak the white rice and water at a ratio of 1:2 for 2 hours, then grind it with a stone mill, and control the particle size range of the white rice flour to 200-300 μm. Then the rice bran slurry and the white rice slurry are uniformly mixed, ground by a stone mill, and the particle size range of the rice bran and white rice flour in the slurry is controlled to be 100-200 μm. Monitor the concentration of the mixed slurry with a...

Embodiment 2

[0039]Select indica brown rice, remove floating ash and mixed gravel and other sundries, wash with pure water, and grind to obtain rice bran and white rice. The method of twin-screw extrusion is adopted, the moisture content of the material is adjusted to 18%, and the rice bran is extruded under the conditions of a temperature of 130° C. and a screw speed of 250 r / min. After the rice bran is cooled, soak the rice bran and water at a ratio of 1:2 for 3 hours, and use a colloid mill to grind the rice bran to control the particle size range of 200-300 μm. Soak the white rice and water at a ratio of 1:2 for 3 hours, then grind it with a stone mill, and control the particle size range of the white rice flour to 200-300 μm. Then the rice bran slurry and the white rice slurry are uniformly mixed, ground by a stone mill, and the particle size range of the rice bran and white rice flour in the slurry is controlled to be 100-200 μm. Monitor the concentration of the mixed slurry with a ...

Embodiment 3

[0041] Select indica brown rice, remove floating ash and mixed gravel and other sundries, wash with pure water, and grind to obtain rice bran and white rice. The twin-screw extrusion method is adopted, the moisture content of the material is adjusted to 30%, and the rice bran is extruded under the conditions of a temperature of 180° C. and a screw speed of 300 r / min. After the rice bran is cooled, soak the rice bran and water at a ratio of 1:4 for 6 hours, and use a colloid mill to grind the rice bran to control the particle size range of 200-300 μm. Soak the white rice and water at a ratio of 1:4 for 6 hours, then grind it with a stone mill, and control the particle size range of the white rice flour to 200-300 μm. Then the rice bran slurry and the white rice slurry are uniformly mixed, ground by a stone mill, and the particle size range of the rice bran and white rice flour in the slurry is controlled to be 100-200 μm. Monitor the concentration of the mixed slurry with a Ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com