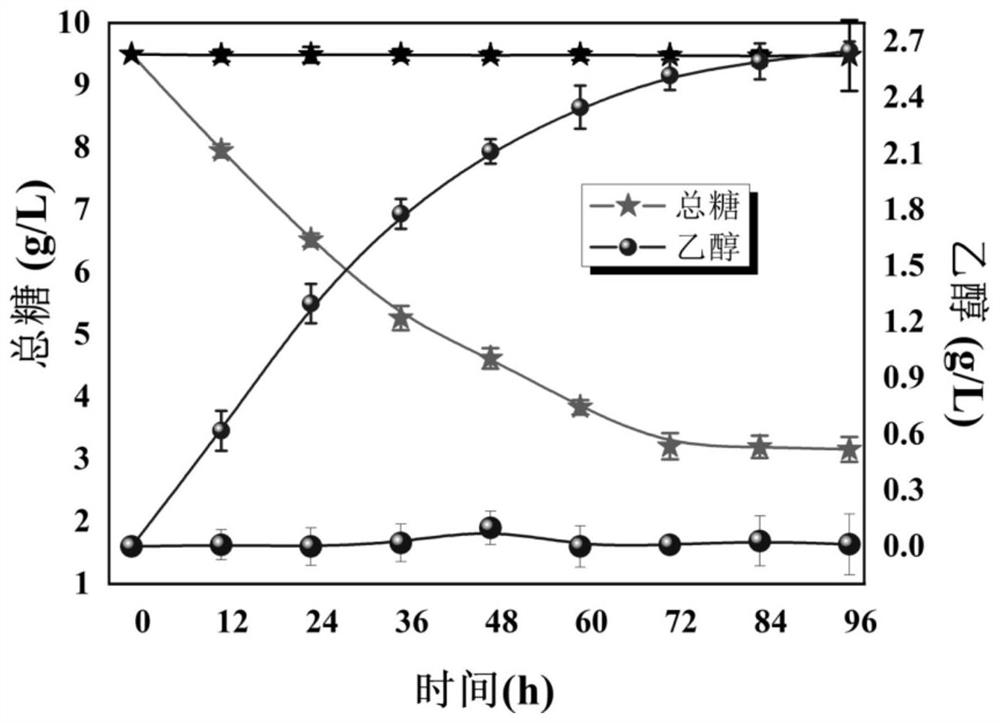

Method for producing ethanol by synchronously performing steam-exploded pennisetum alopecuroides batch feeding and saccharification fermentation

A technology of simultaneous saccharification and fermentation and pennisetum, applied in the field of fermentation, can solve the problems of unfavorable industrial production, lack of direct degradation of lignocellulose substrate performance, and few research reports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1: Construction of recombinant Saccharomyces cerevisiae strain

[0053] 1.1 According to the cohesion module gene sequence published by NCBI (the cohesion module gene and its gene sequence numbers are: CipA (GI: 125972525), CipC (GI: 11056042) and ScaB (GI: 13277318)). The PCR reaction primers were designed, and the primer sequences are shown in Table 1.

[0054] Table 1: Primer sequences for constructing the recombinant vector pYD1-PGK-Aga2-ScafI

[0055]

[0056]The genomes of Clostridium cellulolyticum, Clostridium thermocellum and Ruminococcus flavefaciens were respectively used as templates for gene amplification to amplify the cohesion module gene of the scaffold protein ScafI, and passed the Over- Amplified by lap PCR method. The Over-lap PCR reaction system is: 4.0 μL dNTPs, 2.0 μl Primer CipA-F, 2.0 μL Primer CipC-R, 10.0 μL 5×Q5 Reaction Buffer, 0.5 μL Q5 DNA Polymerase (NEB Co., Ltd.), CipA, CipC and Add 1.0 μL of each ScaB gene to 50.0 μL wi...

Embodiment 2

[0079] Example 2: Construction of self-assembled cellulosomes in Saccharomyces cerevisiae

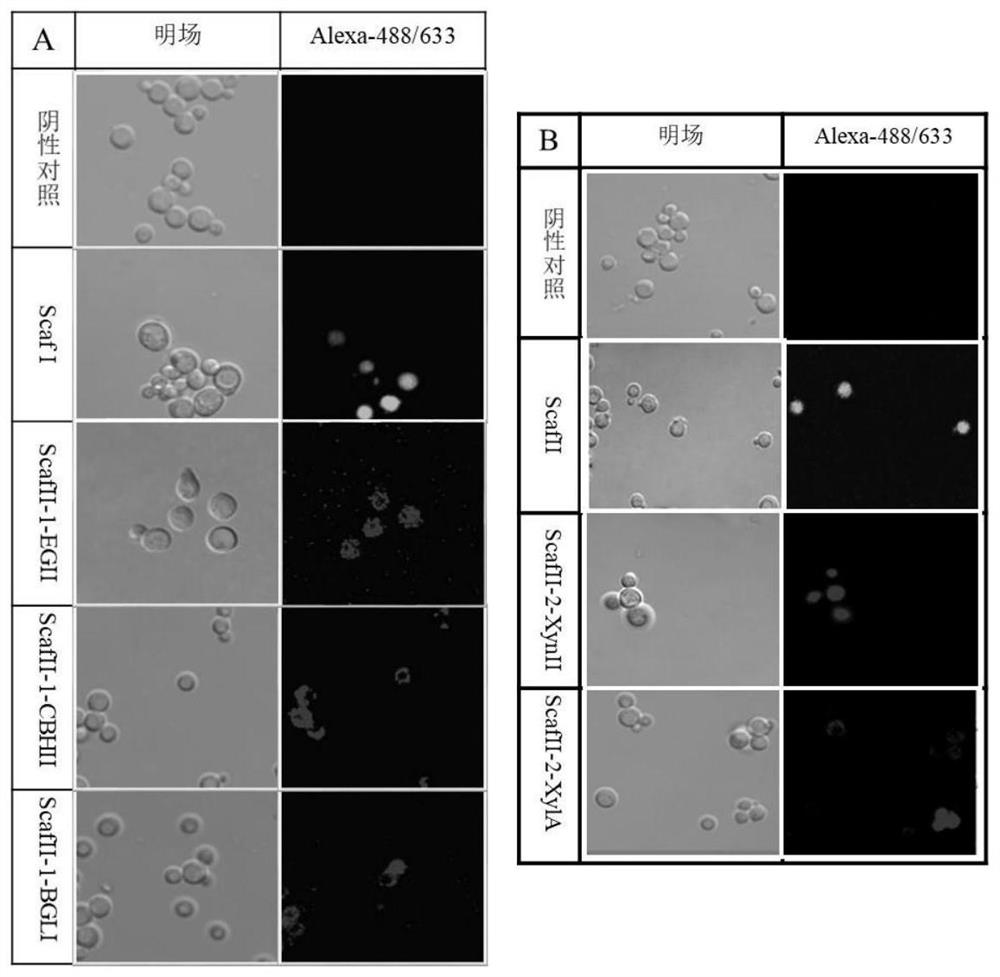

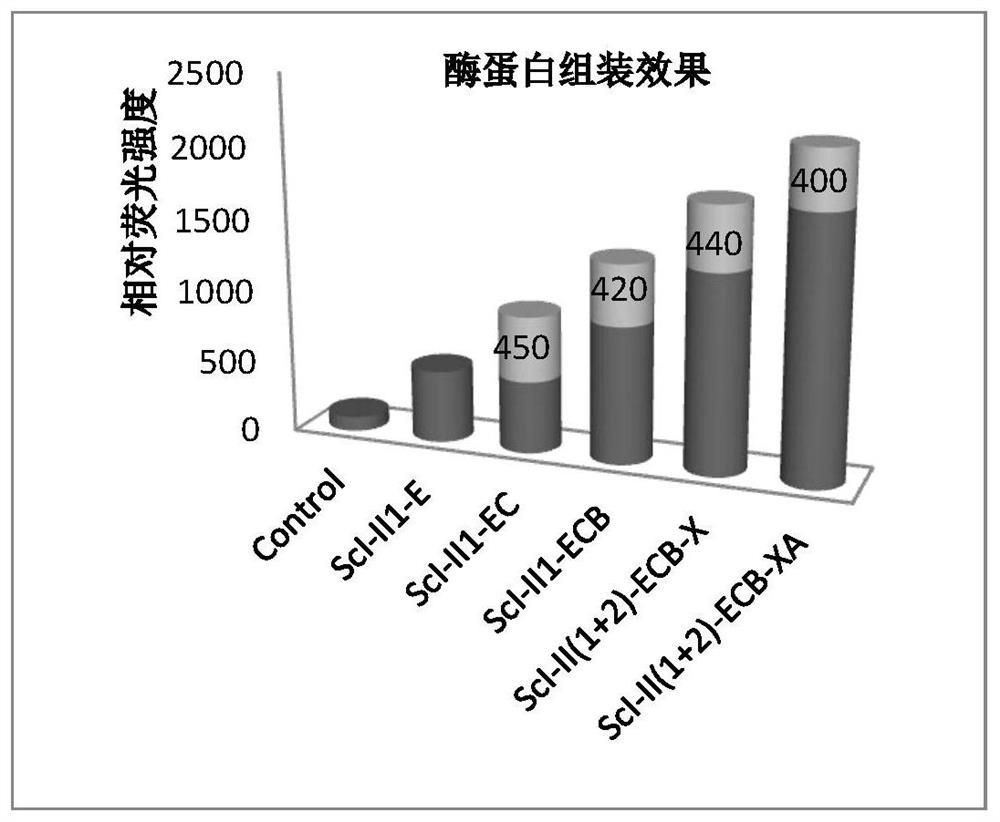

[0080] In YPD (1% yeast extract, 2% peptone, 2% glucose, 10mmoL CaCl 2 , pH is 4.5~6.5) culture medium respectively inserts 1% (v / v) Saccharomyces cerevisiae Y5-ScafI, Y6-1 and Y6-2 cells constructed in embodiment 1, and expresses in embodiment 1 respectively Recombinant strains Y6-EGII, Y6-CBHII, Y6-BGLI, Y6 constructed by transforming Saccharomyces cerevisiae Y6 cells with cellulase (EGII, CBHII and BGLI) and secreted expression plasmids expressing hemicellulase (XylA and XynII) respectively -XylA and Y6-XynII were cultured at 30° C., 150 rpm for 24 hours. Assembly verification was performed using flow cytometry and confocal immunofluorescence microscopy imaging.

[0081] Such as figure 1 As shown, Saccharomyces cerevisiae Y5 cells transformed with pYD1 empty vector were used as a negative control (NegativeControl). The C-terminus of ScafI, the primary scaffold protein of cellulos...

Embodiment 3

[0082] Example 3: Determination of Enzyme Activity of Cellulases and Hemicellulases

[0083] (1) Enzyme activity assay of EG II and CBH II: After culturing recombinant yeast cell Y6-EGII or Y6-CBHII in SD liquid medium (Meitan, M300-03) for 48 hours, take 500 μl of crude enzyme solution in a test tube, add 1 mL of substrate (EGII substrate is 1 % carboxymethyl cellulose (Carboxymethyl Cellulose, CMC), prepared with 0.2mM citric acid buffer, pH 5.0; the substrate of CBHII is 1% PASC, prepared with 0.2mM sodium acetate buffer, pH 5.0), vortex After shaking and mixing, react in a water bath at 50°C for 30 minutes, then add 2.5 mL of DNS chromogenic solution, boil for 5 minutes, cool it rapidly in ice water, and add ultrapure water to make up to 25 mL. Absorbance was measured at 540 nm by a UV-Vis spectrophotometer. Three samples were tested respectively, and the average value of the absorbance value was taken. In the control group, first add DNS chromogenic solution to warm b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com