Cellulase preparation and application thereof

A cellulase and enzyme preparation technology, applied in the directions of enzymes, enzymes, hydrolase, etc., can solve the problems of high equipment requirements, reduced activity and stability, complex processes, etc., and achieve high fermentable sugar yield and high fermentable sugar. Yield, simple effect of saccharification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The screening of embodiment 1β-1,4-glucosidase

[0060] For effective feedback inhibition of cellobiose exposure, it is necessary to select β-1,4-glucosidase with high activity, high stability and high glucose tolerance.

[0061] Selection of β-1,4-glucosidases from Pyrolyticum genus, Thermoanaerobacillus, Clostridium and metagenomics were performed in Escherichia coli BL21(DE3) in a conventional manner. Recombinant expression was carried out in , and the protein was purified by affinity chromatography. The purified protein was tested for enzymatic activity using pNPG as a substrate, and the enzymatic properties were analyzed and compared (see Table 1).

[0062] The enzyme activity detection system is 200μL, which includes 50mM sodium acetate and 1mM pNPG, adding enzyme to start the catalytic reaction, adding 1mL sodium carbonate to stop the reaction after 5-10 minutes of reaction, and detecting the visible light absorption at 405nm, and according to the following The...

Embodiment 2

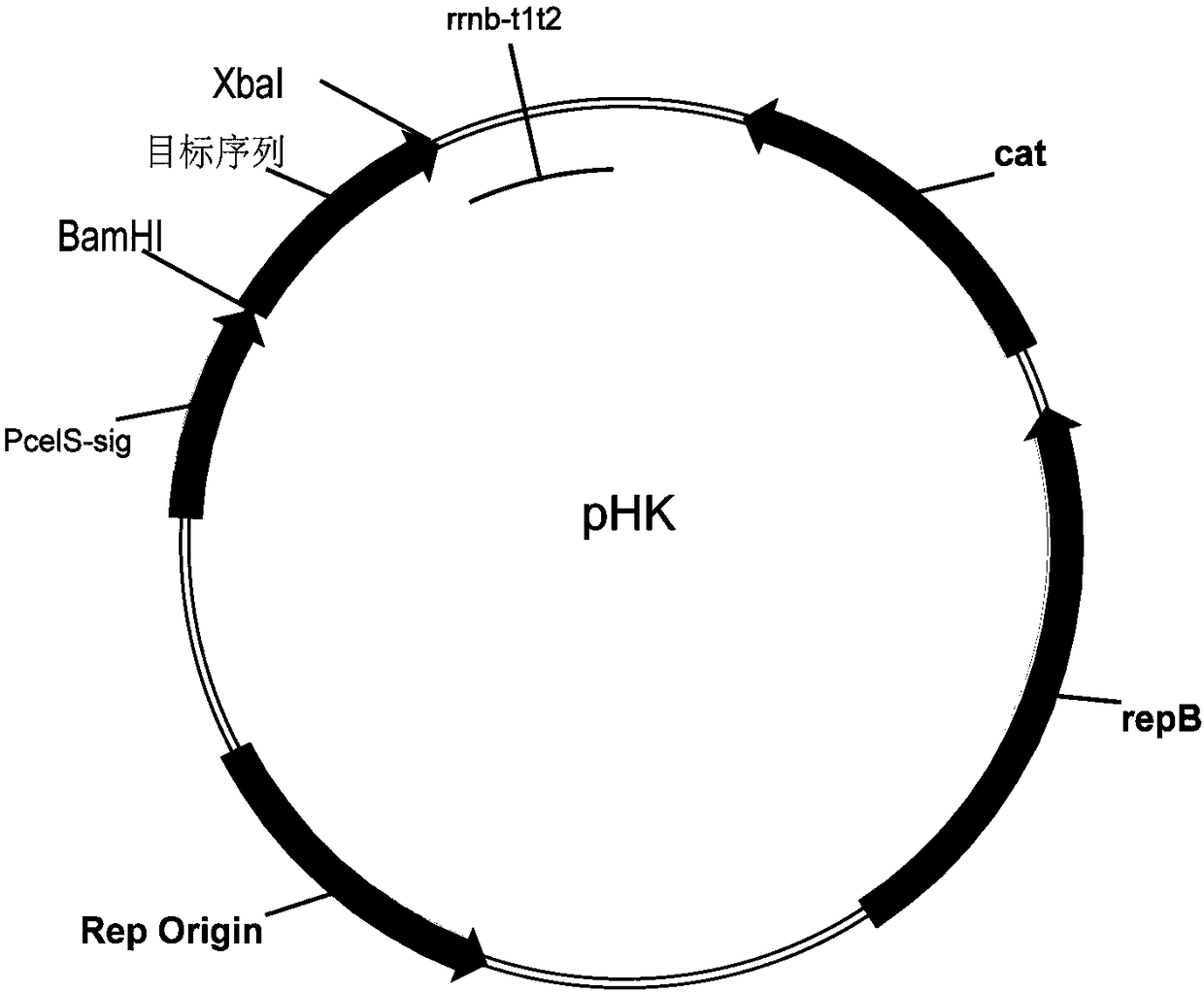

[0067] Construction of a recombinant strain of Clostridium thermocellum expressing β-1,4-glucosidase with type II adhesion module

[0068] Using the method of overlap extension polymerase chain reaction, β-1,4-glucosidase CtBglA (Table 1, SEQ ID NO: 6) is connected with the sequence (SEQ ID NO: 5) of type II cohesion module CohII, wherein The sequence of CohII is linked to the 3' end of the CtBglA sequence. Using BamHI and XbaI restriction sites again, the recombinant sequence connected together was cloned into the expression plasmid pHK( figure 1 )superior. Since pHK carries the promoter and signal peptide sequence (SEQ ID NO: 9) of the cellulase Cel48S derived from Clostridium thermocellum, the expressed target gene can be secreted to the extracellular space. The constructed plasmid was transformed into Clostridium thermocellum DSM1313, thereby obtaining a Clostridium thermocellum recombinant strain DSM1313::pHK-CtBglA-CohII expressing β-1,4-glucosidase with type II cohes...

Embodiment 3

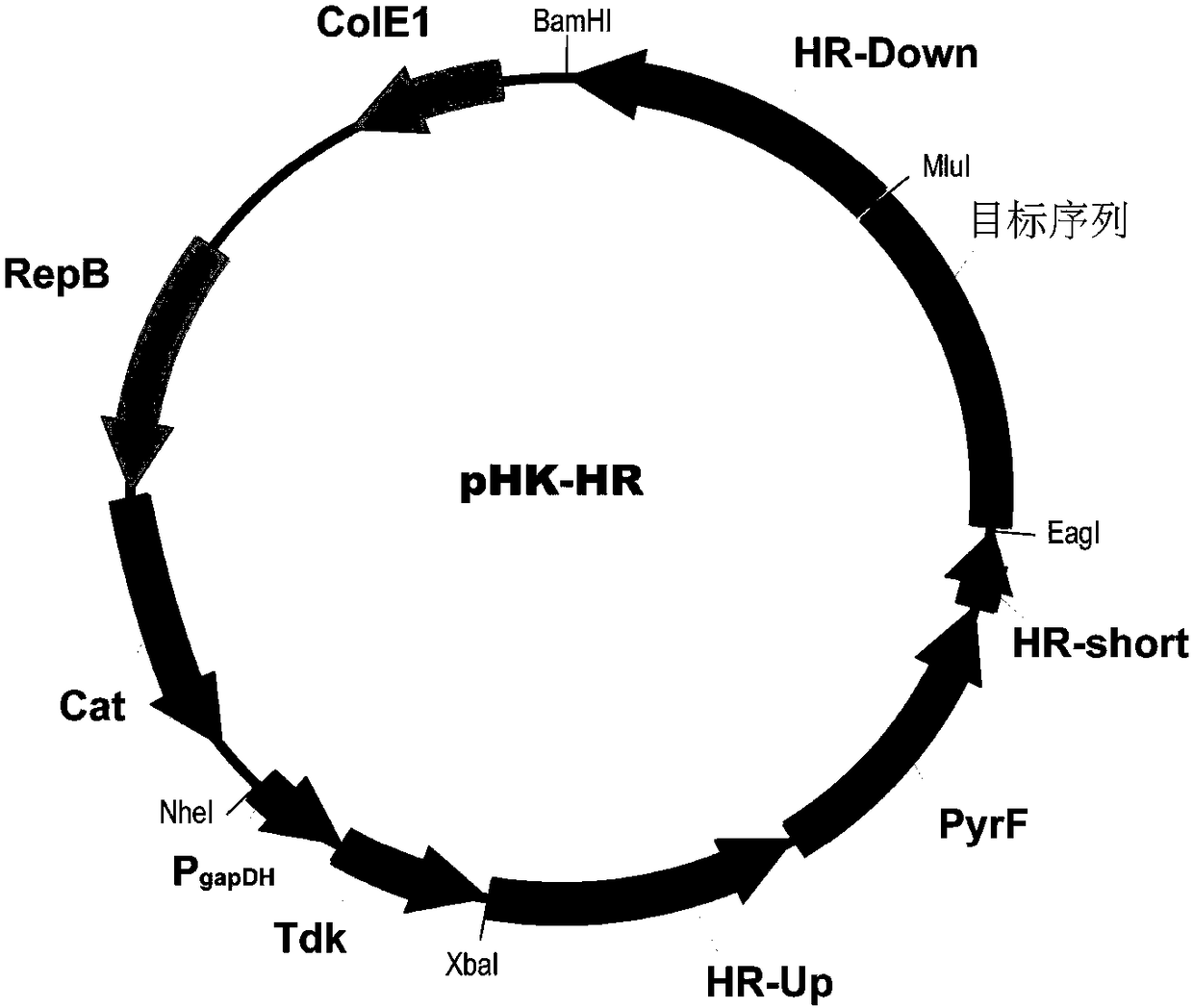

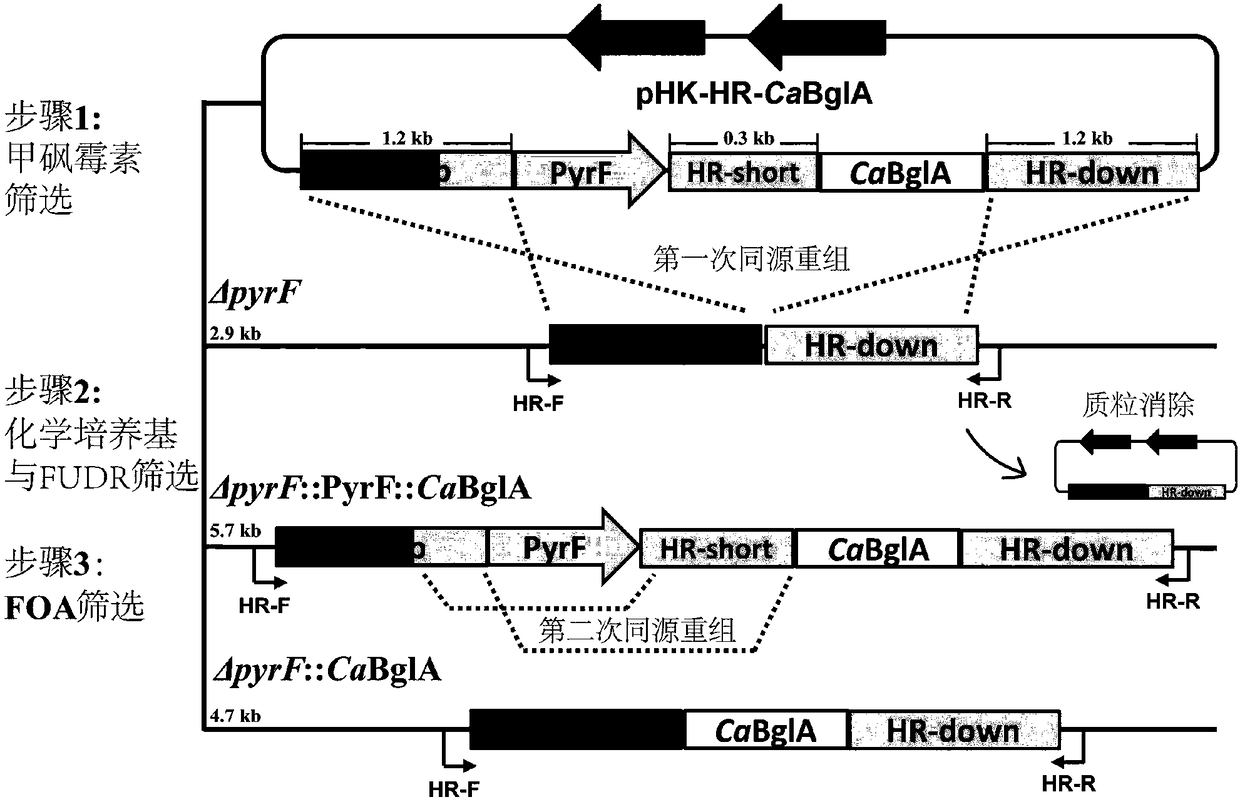

[0074] Construction of Scarless Genetic Operating System of Clostridium thermocellum

[0075] In order to achieve the precise editing of the DNA sequence on the genome of Clostridium thermocellum DSM1313, a Clostridium thermocellum scarless genetic operating system was established, including the mutant strain ΔpyrF of the pyrF knockout Clostridium thermocellum as the chassis cell of the system, and a homologous recombination plasmid pHK-HR( figure 2 ). The homologous recombination plasmid includes two selectable markers and three homology arms. Among them, the screening markers are bidirectional screening marker pyrF and reverse screening marker tdk; the three homology arms include two long homology arms (HR-up, HR-down, about 1200bp), and the middle of the front and rear homology arms Short homology arm (HR-short, about 300bp), wherein the middle short homology arm has the same sequence as the 3' end of the front homology arm to ensure the occurrence of the second homologou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com