Preparation method of variable-thickness resin matrix composite structure

A composite material and variable thickness technology, applied in the field of resin matrix composite material structure molding, can solve the problems that restrict the popularization and application of variable thickness resin matrix composite material structure, uneven distribution of fiber body, and it is difficult for composite material structure to have high thickness accuracy characteristics, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

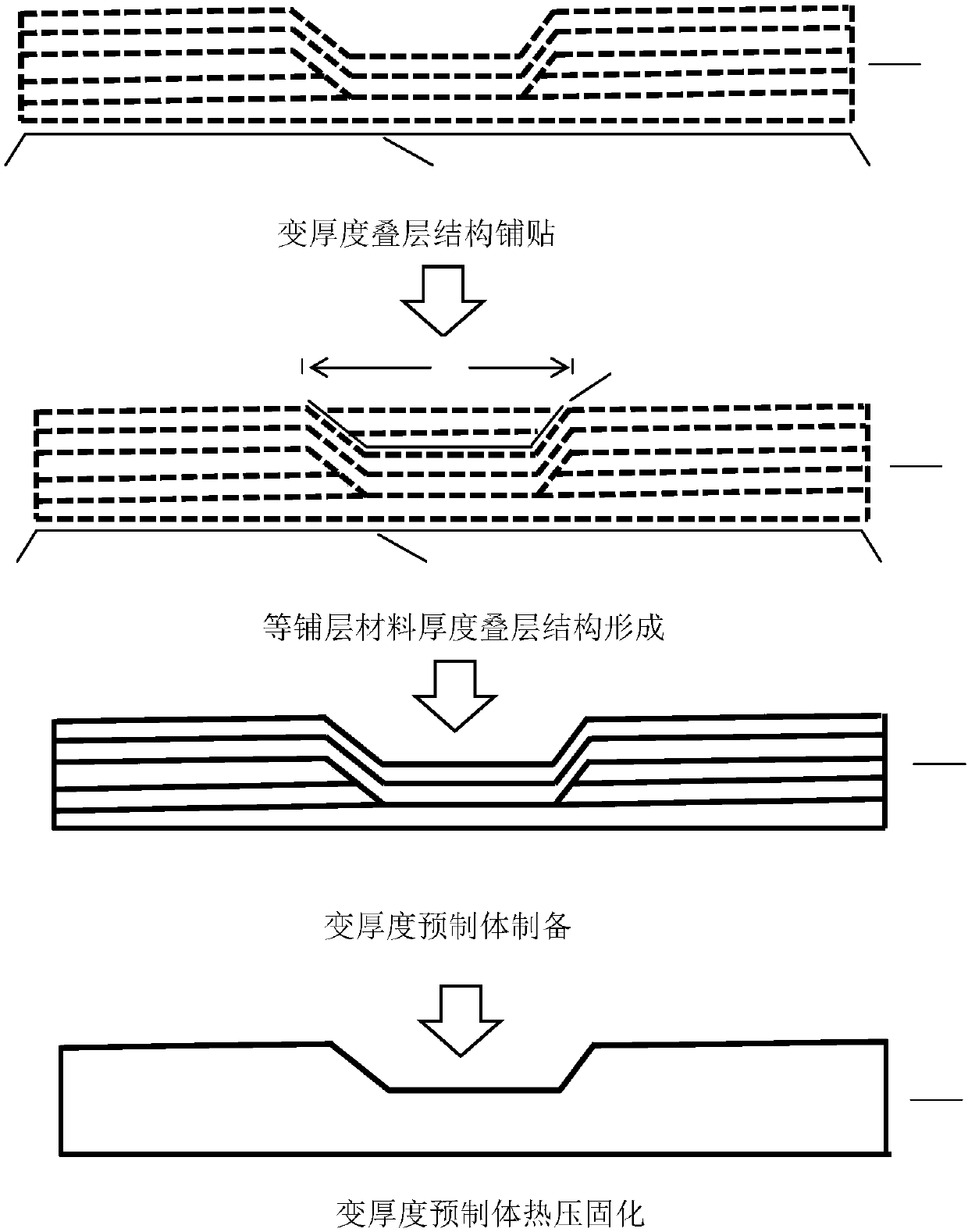

[0017] see figure 1 , a method for preparing a variable-thickness resin-based composite material structure, the specific steps are as follows:

[0018] 1) Laying of variable-thickness laminated structures: paving a laminated material on the mold 1 to form a variable-thickness laminated structure a. The laminated materials include prepregs, fiber fabrics or sizing agent fiber fabrics;

[0019] 2) The formation of a laminated structure with the same thickness of the laminated material: the flexible insulating material 3 is laid on the non-die surface of the thin area 2 of the variable thickness laminated structure a, and the same layer material as that of the variable thickness laminated structure a is laid. The material is laid on the flexible isolation material 3 as a compensation material to form a laminated structure b of equal layer material thickness, and the flexible isolation material 3 shown refers to a flexible polytetrafluoro film with a thickness not greater than 0.0...

Embodiment 1

[0022] Example 1: Using the autoclave-prepreg process to prepare a resin-based composite skin A with a variable thickness with a sunken area, wherein the P4 / P6 / P8 / P9 / P11 / P13 layup of the skin A is a frame type Lost layer structure, the specific preparation method is as follows:

[0023] 1) Cut the prepreg layup sheets including P4 / P6 / P8 / P9 / P11 / P13 of skin A, and cut out the frame-shaped layer loss area of P4 / P6 / P8 / P9 / P11 / P13 layup The remaining frame-shaped prepreg sheets P4L / P6L / P8L / P9L / P11L / P13L are reserved for future use;

[0024] 2) Lay the skin A prepreg sheet laminate on the surface of the forming mold, use a vacuum bag to pressurize the skin A prepreg sheet laminate, remove the vacuum bag, and place the skin A prepreg sheet A flexible non-porous PTFE isolation film with a thickness of 0.01mm is placed in the thin area of the material laminate, and then the frame-shaped prepreg sheet P4L / P6L / P8L / P9L / P11L / P13L is laid on the flexible polytetrafluoroethylene On the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com