Processing biomass

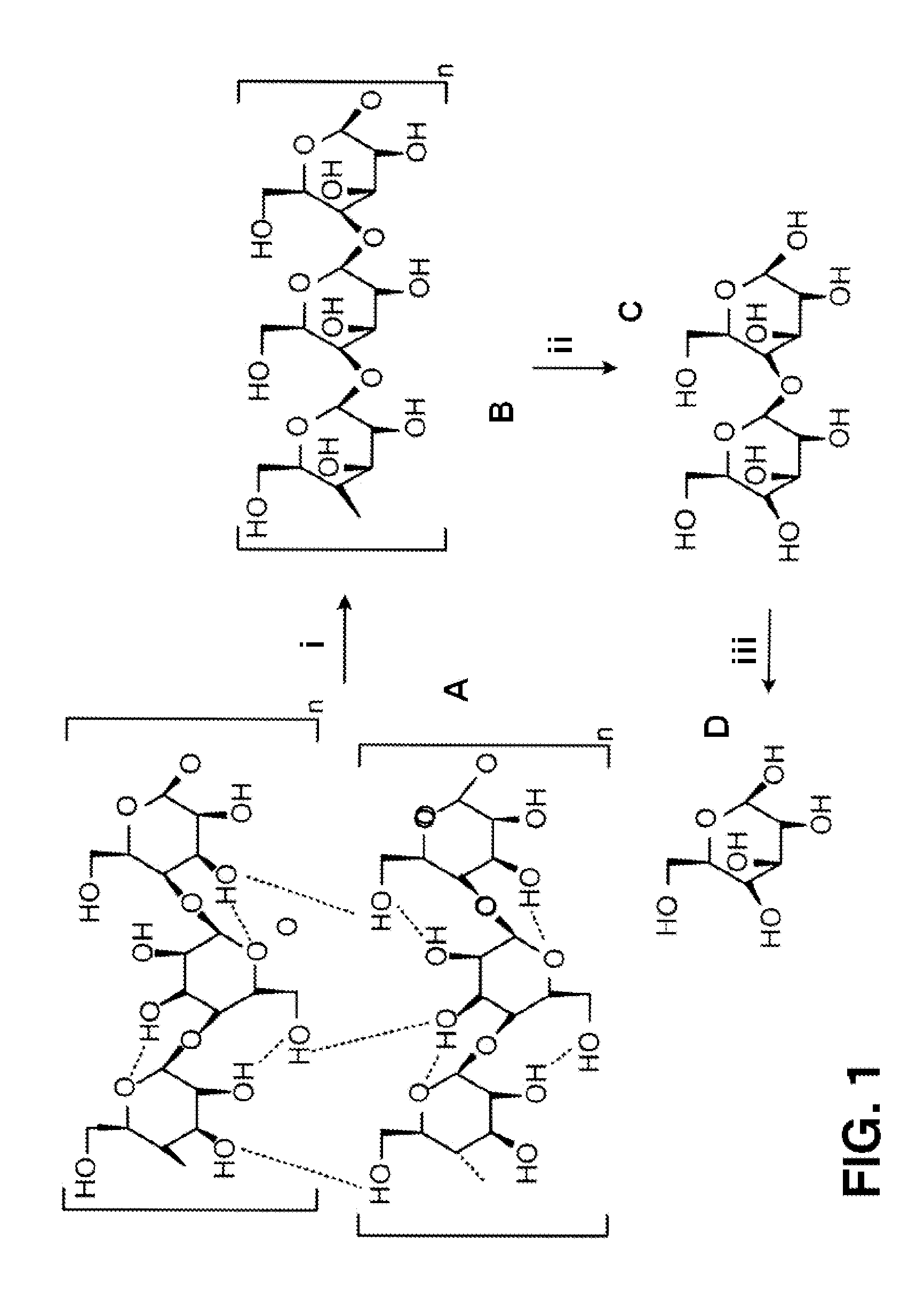

a technology of biomass and saccharification, applied in the direction of biofuels, energy-based chemical/physical/physicochemical processes, fungi, etc., can solve the problems of low yield of naturally occurring cellulosic materials, low yield of theoretical yields, and high cost, so as to avoid negative feedback inhibition of enzymatic reactions and increase the efficiency of saccharification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Effect of Exogenous Fructose on Saccharification

[0206]This example tests whether or not exogenous fructose inhibits saccharification enzymes.

[0207]Three 225 mL Erlenmeyer flasks were prepared, each with 10 g of treated corn cob biomass (mesh size between 15 and 40, and irradiated to 35 Mrad with an electron beam) 100 mL of water and 2.5 mL of Duet Accelerase™ (Danisco). To the first, second, and third flask were added, respectively: 0 g, 5 g and 10 g of fructose. The flasks were covered with aluminum foil and set in an incubator shaker at 50° C. and 200 rpm for four days. The amount of xylose and glucose was monitored by HPLC. The results of the saccharification are shown in the table below.

TABLE 1Saccharification under varying levels of exogenous fructose.GlucoseSampleyield (g / L)Xylose yield (g / L)% Glucose0 g added fructose17.913.8100.05 g added fructose16.712.393.510 g added fructose 18.112.6101.3

[0208]Unlike glucose (a known inhibitor of cellobiase), 5% or 10% added fructose does...

example 2

Effect of Xylose Isomerase on Saccharification

[0209]Glucose is a known inhibitor of cellobiase. This example tests if the conversion of glucose to the isomer fructose by xylose isomerase can increase saccharification.

[0210]Four 225 mL Erlenmeyer flasks were prepared, each with 10 g of treated corn cob biomass and 100 mL of water. The biomass was treated as described in Example 1. To the first, second, and third flask was added 2.5 mL of Duet Accelerase™ (Danisco). To the second, third, and fourth flasks were added, respectively: 1 g, 0.1 g and 0.1 g of glucose isomerase (Sweetzyme™, Aldrich). The flasks were covered with aluminum foil and set in an incubator shaker at 50° C. and 200 rpm for four days. The amount of xylose and glucose was monitored by HPLC. The results of the saccharification are shown in the table below.

TABLE 2Effectiveness of cellulase with added xylose isomerase.GlucoseXylose%Sampleyield (g / L)yield (g / L)Glucose% Xylose2.5 mL Duet22.616.9100.1100.02.5 mL Duet + 1 g...

example 3

Use of a Strong Acid to Cleave Cellobiose

[0212]This example tests the use of a strong acid to cleave cellobiose to glucose, to increase saccharification yield. The strong acid used was Amberlyst-15™, a polystyrene sulfonic acid. This is a strongly acidic sulfonic acid macroreticular polymeric resin that is based on crosslinked styrene divinylbenzene copolymers. Published studies indicate that Amberlyst-15 can cleave the dimer cellobiose to glucose.

[0213]Three 225 mL Erlenmeyer flasks were prepared, each with 10 g of treated corn cob biomass, 100 mL of water and 2.5 mL Duet Accelerase™. The biomass was treated as described in Example 1. In the second flask 1 g of glucose isomerase (Sweetzyme™, Aldrich) was added; and in the third 1 g of glucose isomerase and 0.1 g of polystyrene sulfonic acid (Amberlyst-15™, DOW) was added.

[0214]The flasks were covered with aluminum foil and set in an incubator shaker at 50° C. and 200 rpm for four days. The amount of xylose and glucose was monitored...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com