Preparation process of maltooligosaccharide syrup with high maltotetraose content

The technology of maltotetraose and maltose syrup is applied in the field of preparation of maltose oligosaccharide, which can solve the problem of inability to meet the requirement of adding high-end products, and achieve the effects of rapidly adjusting metabolic rate, reducing production cost and improving saccharification efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

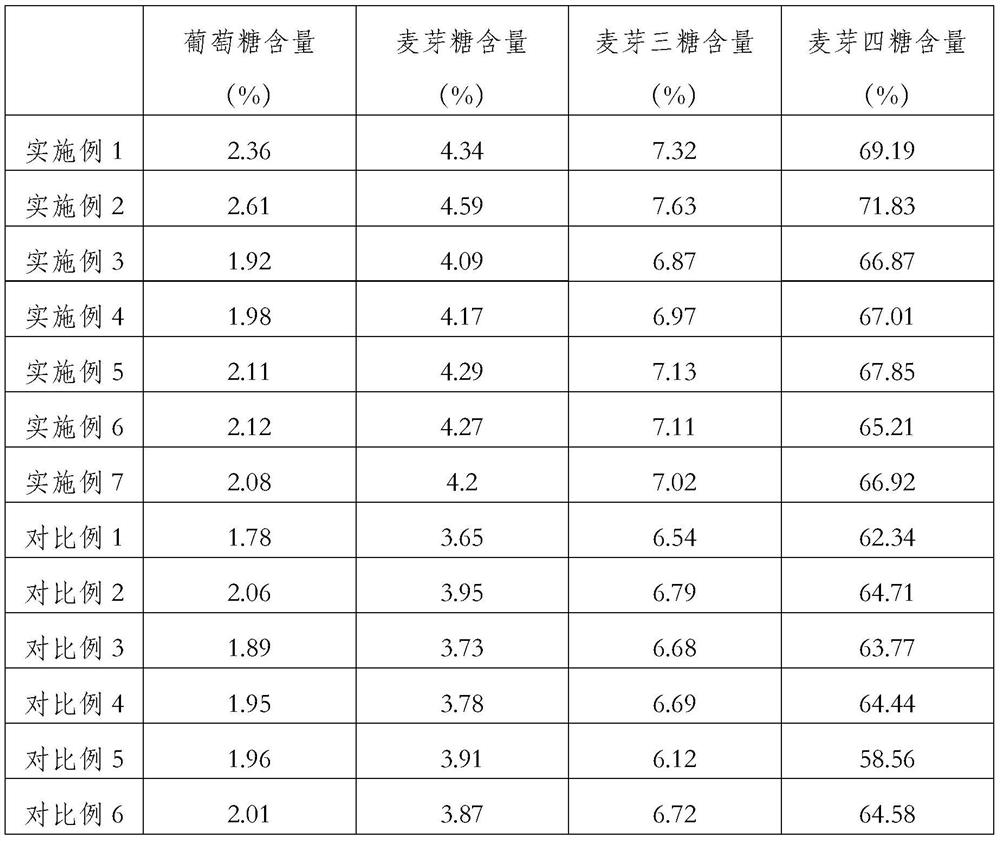

Examples

Embodiment 1

[0038] (1) adding water to cornstarch to form starch slurry, the mass concentration of dry matter in the starch slurry is 13%, and the pH of the starch slurry is adjusted to be 6.0;

[0039] (2) adding high temperature resistant α-amylase to the starch slurry in (1), the addition amount is 0.01L / ton of starch;

[0040] (3) The feed liquid in (2) was liquefied by spraying once at 110°C for 15 minutes, kept in a laminar flow tank for 80 minutes, and liquefied by spraying twice at 130°C for 10 minutes to obtain a liquefied liquid with a DE value of 4.2%.

[0041] (4) Rapidly cooling the liquefied liquid prepared in (3) to 60° C. through a flash heat exchanger;

[0042] (5) First add pullulanase to the feed solution in (4) to react for 1 hour, then add maltotetraose for saccharification reaction, the addition amount of both maltotetraose and pullulanase is 0.5L / ton of starch , after 12 hours of saccharification reaction, the reaction solution was obtained;

[0043] (6) Decoloriz...

Embodiment 2

[0048] (1) adding water to cornstarch to form starch slurry, the mass concentration of dry matter in the starch slurry is 21.5%, and the pH of the starch slurry is adjusted to be 6.0;

[0049] (2) adding high temperature resistant α-amylase to the starch slurry in (1), the addition amount is 0.01L / ton of starch;

[0050] (3) The feed liquid in (2) was liquefied by spraying once at 110°C for 15 minutes, kept in a laminar flow tank for 80 minutes, and liquefied by spraying twice at 130°C for 10 minutes to obtain a liquefied liquid with a DE value of 3.8%;

[0051] (4) Rapidly cooling the liquefied liquid prepared in (3) to 60° C. through a flash heat exchanger;

[0052] (5) First add pullulanase to the feed solution in (4) to react for 1 hour, then add maltotetraose for saccharification reaction, the addition amount of both maltotetraose and pullulanase is 0.5L / ton of starch , after 12 hours of saccharification reaction, the reaction solution was obtained;

[0053] (6) Decolor...

Embodiment 3

[0055] (1) adding water to cornstarch to form starch slurry, the mass concentration of dry matter in the starch slurry is 21.5%, and the pH of the starch slurry is adjusted to be 6.0;

[0056] (2) adding high temperature resistant α-amylase to the starch slurry in (1), the addition amount is 0.045L / ton of starch;

[0057] (3) The feed liquid in (2) was liquefied by spraying once at 110°C for 15 minutes, kept in a laminar flow tank for 80 minutes, and liquefied by spraying twice at 130°C for 10 minutes to obtain a liquefied liquid with a DE value of 5.3%;

[0058] (4) Rapidly cooling the liquefied liquid prepared in (3) to 60° C. through a flash heat exchanger;

[0059] (5) First add pullulanase to the feed solution in (4) to react for 1 hour, then add maltotetraose for saccharification reaction, the addition amount of both maltotetraose and pullulanase is 0.5L / ton of starch , after 12 hours of saccharification reaction, the reaction solution was obtained;

[0060] (6) Decolo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com