Method for producing ethyl alcohol by using sorgo stalk

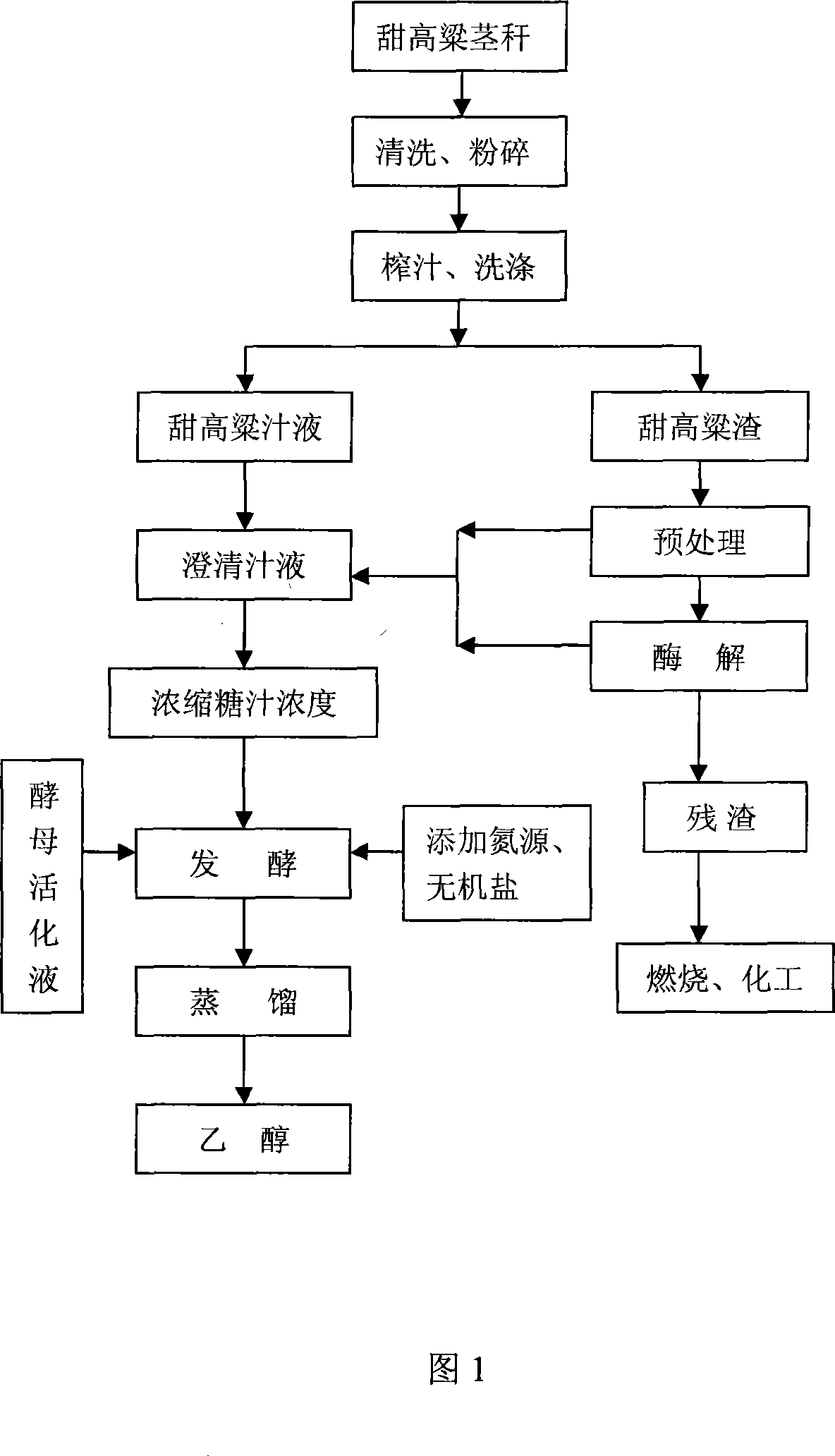

A technology of sweet sorghum and stalks, which is applied in the field of ethanol production by using sweet sorghum stalks, which can solve the problems of low utilization rate of raw materials, air and environmental pollution, waste, etc., and achieve energy saving, high utilization rate and high ethanol yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The production of ethanol using sweet sorghum stalks comprises the following steps:

[0031] (1) Extracting juice from sweet sorghum stalks: 100 kilograms of sweet sorghum stalks with a water content of 72.8%, a sugar content of 13.9%, and a crude fiber content of 9.6% are crushed and cut into filamentary segments of 10 mm to 25 mm, and squeezed with a press machine. Then adding water to the obtained sweet sorghum dregs for secondary pressing to obtain sweet sorghum juice and silky sweet sorghum dregs with extremely low residual sugar content;

[0032] (2) Cooking sweet sorghum stalk juice at 100° C. for 30 minutes, centrifuging and filtering, removing sediment to obtain clarified sweet sorghum juice.

[0033](3) Dilute acid blasting pretreatment of sweet sorghum slag Naturally air-dried sweet sorghum slag, washed with 0.1% H 2 SO 4 Soak in the solution for 12 hours, put into the closing device of the steam explosion tank; keep it under the pressure of 1.5MPa for 6 mi...

Embodiment 2

[0039] The production of ethanol using sweet sorghum stalks comprises the following steps:

[0040] (1) Juicing of sweet sorghum stalks with 72.8% water content, 13.9% sugar content, and 100Kg of sweet sorghum stalks with a crude fiber content of 9.6% are pulverized and cut into filamentous segments of 10mm to 25mm, squeezed with a press, and then Adding water to the obtained sweet sorghum dregs and performing secondary pressing to obtain sweet sorghum juice and silky sweet sorghum dregs with very low residual sugar content.

[0041] (2) Cooking the sweet sorghum stalk juice obtained in step (1) at 100° C. for 30 minutes, centrifuging and filtering, and removing sediment to obtain clarified sweet sorghum juice.

[0042] (3) Sweet sorghum slag dilute acid blasting pretreatment Air-dry the sweet sorghum slag obtained in step (1), wash with 0.5% H 2 SO 4 Soak in the solution for 8 hours, put it into the steam explosion tank, and close the device; quickly increase the pressure, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com