Biological-ionic liquid combined pretreatment method of lignocellulose

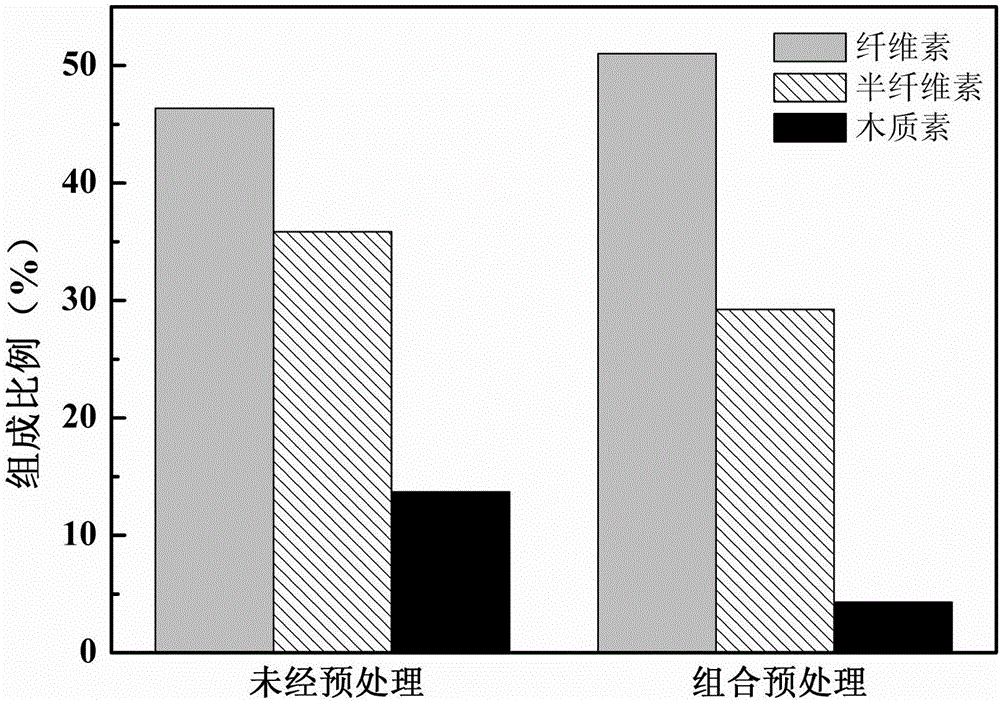

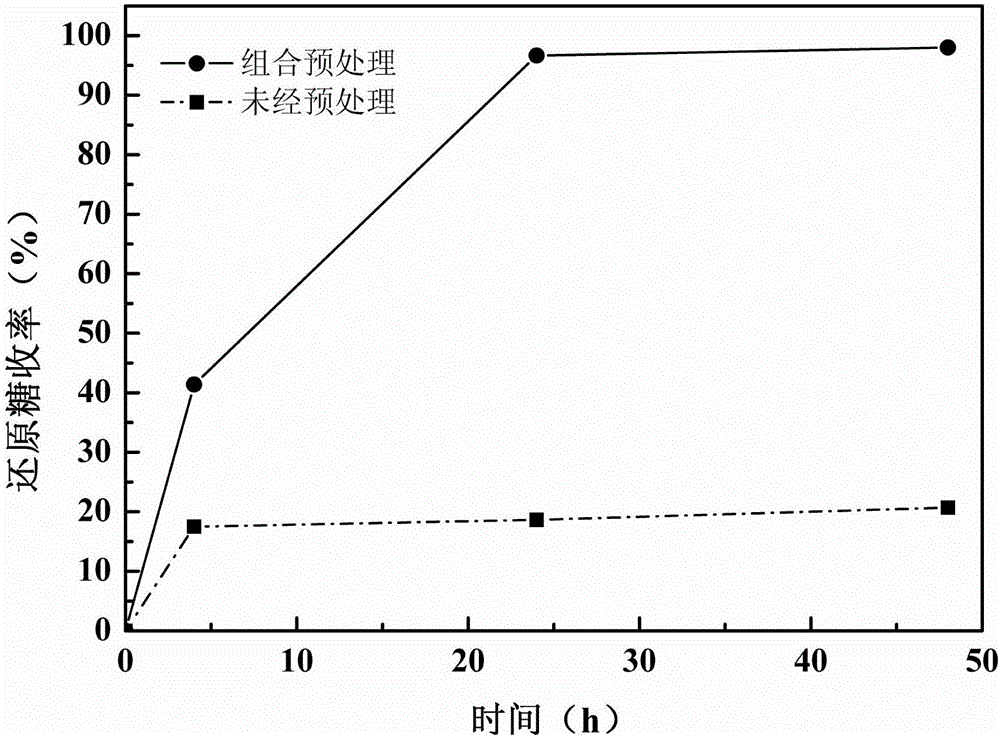

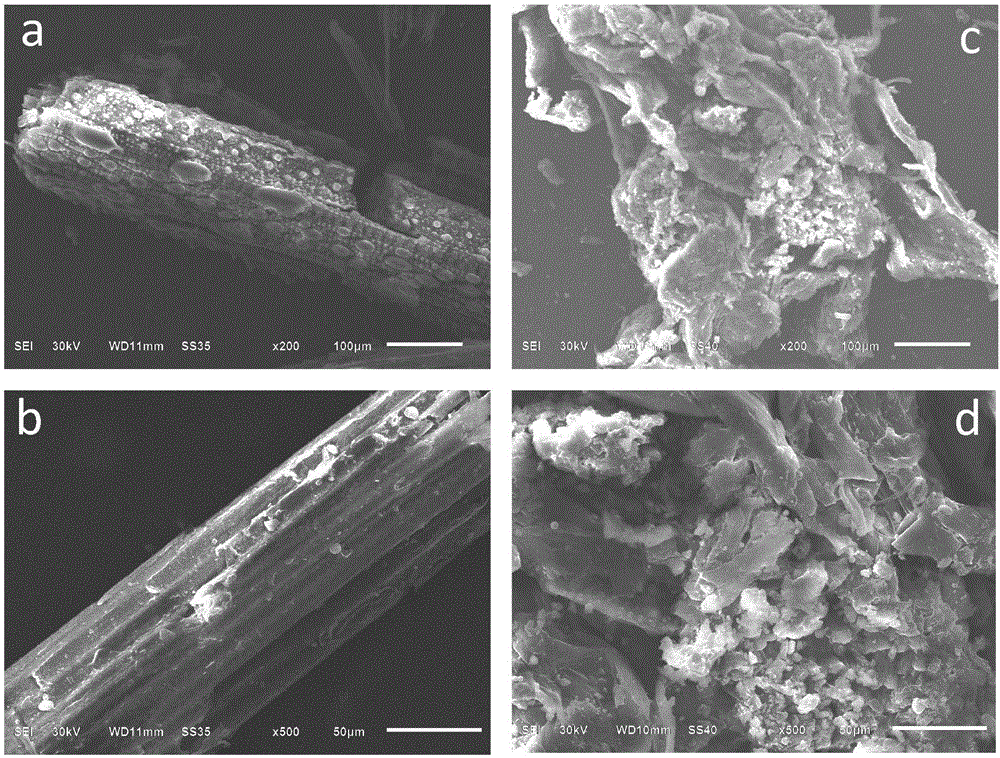

A technology of lignocellulose and ionic liquid, which is applied in the field of lignocellulose raw material pretreatment, can solve the problems of low efficiency, long pretreatment time, loss and development of sugar components, etc., to simplify the process, preserve cellulose content, reduce The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Washing, drying and pulverizing the rice straw, controlling its particle size distribution between 180 μm and 425 μm;

[0029] (2) Inoculate the LD-1 cells stored on the LB slope into the LB liquid medium, and cultivate at 30° C. for 18 hours to obtain the seed liquid of LD-1;

[0030] (3) wherein said LB liquid culture medium each composition ratio is: peptone 10g, yeast powder 5g, sodium chloride 10g, distilled water 1L, described LB slant is to add the agar of 15g / l on the basis of above-mentioned prescription;

[0031] (4) Centrifuge the LD-1 seed solution obtained in the previous step for 2 minutes at 10,000 rpm, discard the supernatant, and collect the bacteria;

[0032] (5) further inoculate the collected LD-1 thalline into lignocellulose liquid culture medium according to 10% (volume ratio) inoculum amount, and cultivate for 3 days at a temperature of 30° C. at natural pH;

[0033] (6) wherein said lignocellulose liquid culture medium each composition ratio...

Embodiment 2

[0039] (1) Washing, drying and pulverizing the rice straw, controlling its particle size distribution between 180 μm and 425 μm;

[0040] (2) Inoculate the LD-1 cells stored on the LB slope into the LB liquid medium, and cultivate at 30° C. for 18 hours to obtain the seed liquid of LD-1;

[0041] (3) Wherein said LB liquid culture medium each composition ratio is: peptone 10g, yeast powder 5g, sodium chloride 10g, distilled water 1L, described LB slant is to add the agar of 15g / l on the basis of above-mentioned formula;

[0042] (4) Centrifuge the LD-1 seed solution obtained in the previous step for 2 minutes at 10,000 rpm, discard the supernatant, and collect the bacteria;

[0043] (5) further inoculate the collected LD-1 thalline into lignocellulose liquid culture medium according to 10% (volume ratio) inoculum amount, and cultivate for 3 days at a temperature of 30° C. at natural pH;

[0044] (6) wherein said lignocellulose liquid culture medium each composition ratio is: li...

Embodiment 3

[0050] (1) Washing, drying and pulverizing the rice straw, controlling its particle size distribution between 180 μm and 425 μm;

[0051] (2) Inoculate the LD-1 cells stored on the LB slope into the LB liquid medium, and cultivate at 30° C. for 18 hours to obtain the seed liquid of LD-1;

[0052] (3) Wherein said LB liquid culture medium each composition ratio is: peptone 10g, yeast powder 5g, sodium chloride 10g, distilled water 1L, described LB slant is to add the agar of 15g / l on the basis of above-mentioned formula;

[0053] (4) Centrifuge the LD-1 seed solution obtained in the previous step for 2 minutes at 10,000 rpm, discard the supernatant, and collect the bacteria;

[0054] (5) further inoculate the collected LD-1 thalline into lignocellulose liquid culture medium according to 10% (volume ratio) inoculum amount, and cultivate for 3 days at a temperature of 30° C. at natural pH;

[0055] (6) wherein said lignocellulose liquid culture medium each composition ratio is: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com