Beer brewing saccharifying heating device and beer brewing saccharifying heating method

A technology of a heating device and a heating method, which is applied in the field of beer manufacturing, can solve the problems of large power consumption and uneven heating of liquid, and achieve the effects of small liquid temperature difference, accurate temperature control, and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

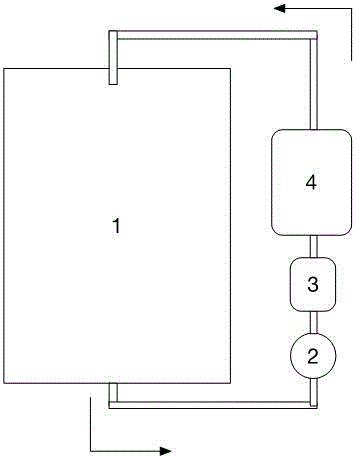

[0018] Please refer to figure 1 , the present invention provides a beer brewing saccharification heating device, comprising: a saccharification container 1 for placing malt, a water pump 3 and a heating module 4, the saccharification container 1 includes a first port and a second port; the first port The water pump 3 and the heating module 4 are sequentially connected to the second port, and the heating module 4 includes a pipe body and an electric heating element located outside the pipe body. Preferably, the first port is located at the bottom of the malt saccharification container 1 , and the second port is located at the top of the malt saccharification container 1 . The electric heating element of the heating module 4 generates heat, which exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com