Method for improving lignocellulose saccharification efficiency

A technology of lignocellulose and saccharification efficiency, applied in the field of biotransformation, can solve the problems of low saccharification efficiency and low saccharification efficiency, and achieve the effect of increasing accessibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

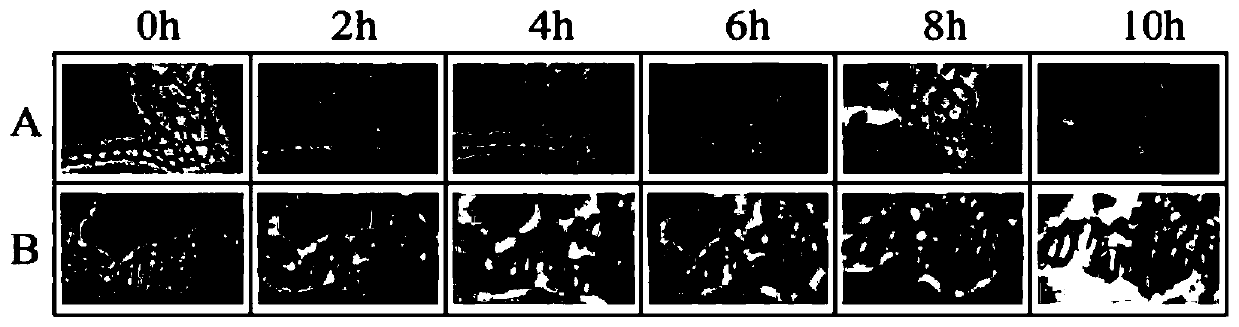

Image

Examples

Embodiment 1

[0031] The method for improving the saccharification efficiency of lignocellulose includes the steps:

[0032] (1) Pretreatment: pretreatment of rice straw, the specific process is,

[0033] (1.1) Select rice straw, clean, dry, crush, sieving, and store in a drying box;

[0034] (1.2) Accurately weigh 20g rice straw powder, put it into a 500mL Erlenmeyer flask, add 93.5mL absolute ethanol and 46.5mL nitric acid, place it in a 76℃ water bath, and react for 3h under normal pressure;

[0035] (1.3) After the reaction is completed, filter the solid with 500 mesh filter cloth, and filter with vacuum pump. Part of the lignin component in the rice straw is nitrated by nitric acid, and the resulting nitrated lignin is dissolved in ethanol solution and washed continuously with deionized water Until the filtrate is clarified to remove solubles and residual nitric acid and ethanol;

[0036] (1.4) Collect the remaining solids, put them in an oven and bake them until the weight no longer changes, g...

Embodiment 2

[0044] The method for improving the saccharification efficiency of lignocellulose includes the steps:

[0045] (1) Pretreatment: pretreatment of rice straw, the specific process is,

[0046] (1.1) Cut corn stalks and crush them to powder;

[0047] (1.2) Weigh 100g of powdered corn stalks, add 1000ml of deionized water, add 30g of sodium chlorite and 10ml of glacial acetic acid, place in the reactor, heat to 75°C, add 30g of sodium chlorite and 10ml of glacial acetic acid every 10min. React for 40 minutes to obtain a mixture.

[0048] (1.3) After the reaction is completed, filter the filter residue with a 500 mesh filter cloth, and continuously wash the filter residue with deionized water until the filtrate is clarified to obtain delignified corn stover.

[0049] (2) Enzymatic hydrolysis: add cellulase, enzymatic hydrolysis additives, and solvents to the delignified corn stalks for enzymatic saccharification. The specific process is to add 50 mg of cellulase (1u / mg) to the delignified c...

Embodiment 3

[0052] The method for improving the saccharification efficiency of lignocellulose includes the steps:

[0053] (1) Pretreatment: pretreatment of rice straw, the specific process is,

[0054] (1.1) Cut corn stalks and crush them to powder;

[0055] (1.2) Weigh 40g of powdered corn stalks, add 400ml of deionized water, add 12g of sodium chlorite and 4ml of glacial acetic acid, place in the reactor, heat to 75℃, add 12g of sodium sulfite and 4ml of glacial acetic acid every 10min, and react for 20min to obtain mixture;

[0056] (1.3) After the reaction is completed, filter the filter residue with a 500 mesh filter cloth, and continuously wash the filter residue with deionized water until the filtrate is clarified to obtain delignified corn stalks. The delignified corn stalk is chemically pretreated with Phanerochaete chrysosporium Nutrients required for the enzyme production medium, sterilized at 121°C and inoculated with Phanerochaete chrysosporium for pretreatment;

[0057] (1.4) After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com