Method for separating lignin and holocellulose from wood fiber raw materials and application thereof

A technology of lignocellulosic raw materials and comprehensive cellulose, which is applied in the field of utilization of agricultural and forestry biological materials, can solve the problems of insufficient biomass-based substitute products and the inability to use lignocellulosic raw materials, etc., and achieve simple and easy process, high saccharification efficiency, and extraction yield high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

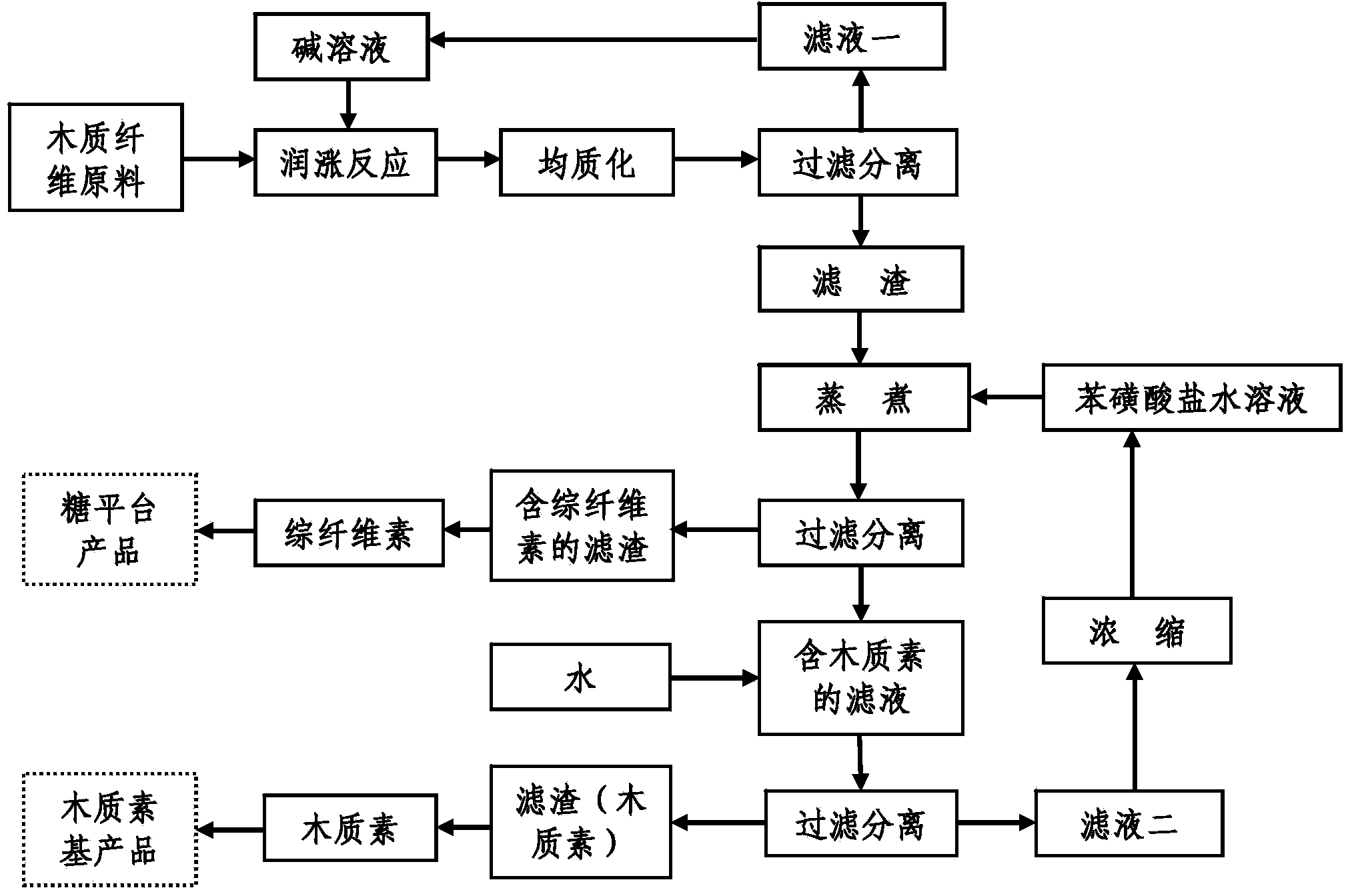

Image

Examples

Embodiment 1

[0035] Embodiment 1: separate lignin from bamboo powder

[0036] This embodiment has the following steps:

[0037] (1) Grind the bamboo until the particle size is less than 2mm, add 100g of bamboo powder to 500mL of 10% sodium hydroxide solution, stir evenly at room temperature, heat at 120°C for 60min, cool naturally to room temperature, and soak to moisten rising bamboo powder;

[0038] (2) Add the bamboo powder soaked and moistened into the homogenizer feed hopper, stir to keep the material in suspension, then pass through the homogenizer, while circulating the material and gradually increase the pressure, when the pressure reaches 80MPa, start to collect the material, and the material Vacuum filtration to separate solid and liquid to obtain solid filter residue, which is washed with water;

[0039] (3) the solid filter residue that step (2) obtains is joined in 40% sodium cumene sulfonate aqueous solution, the mass volume ratio of residue and sodium cumene sulfonate solu...

Embodiment 2

[0046] The difference between this embodiment and embodiment 1 is that in step (1), 100g of bamboo powder is added to 1000mL of 1% potassium hydroxide aqueous solution in parts by mass.

Embodiment 3

[0048] The difference between this embodiment and embodiment 1 is that in step (2) when the pressure reaches 100MPa, the material starts to be collected.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com