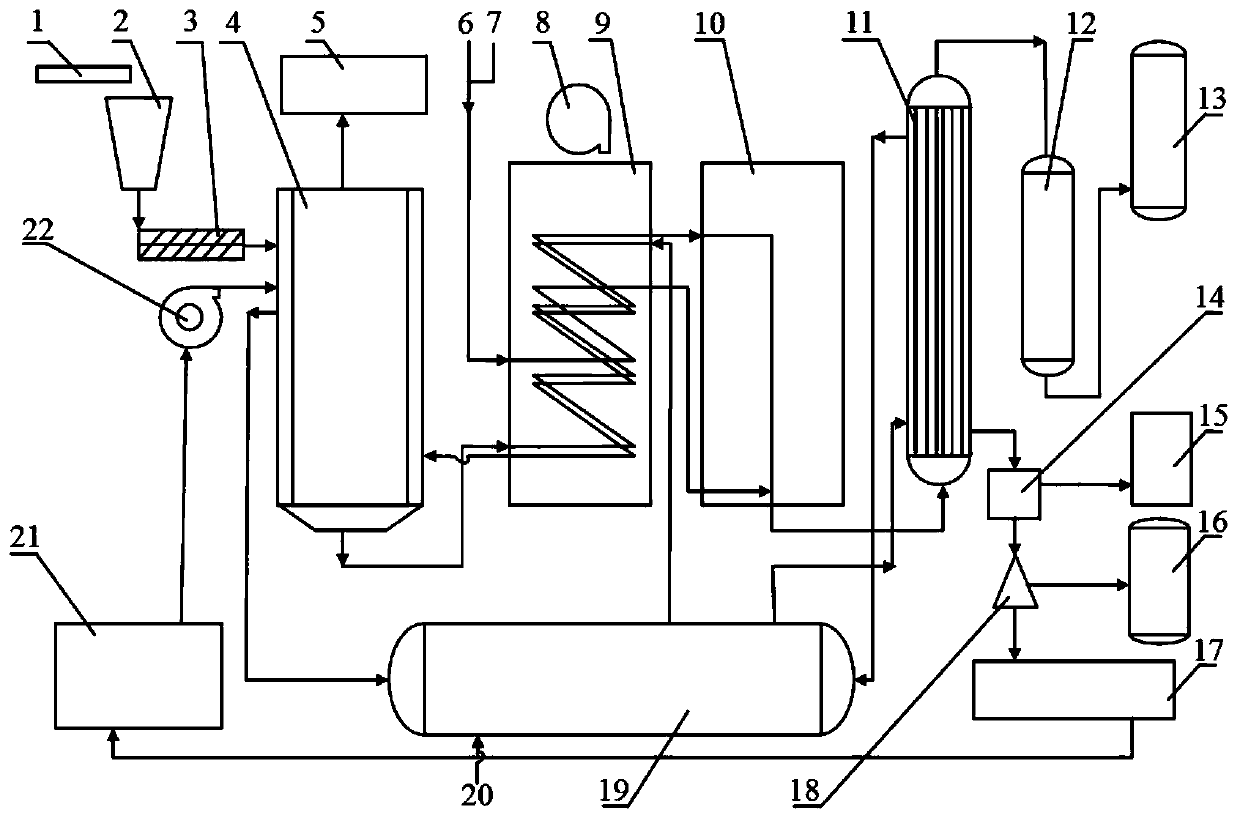

A kind of lignin separation and steam cracking system and method

A cracking system and lignin technology, which is applied in the preparation of hydrocarbon oil, liquid hydrocarbon mixture, petroleum industry, etc., can solve the problems of unstable cracking process, difficult control of gasifier, low product quality, etc., and achieve low working temperature , stable cracking process and high extraction recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

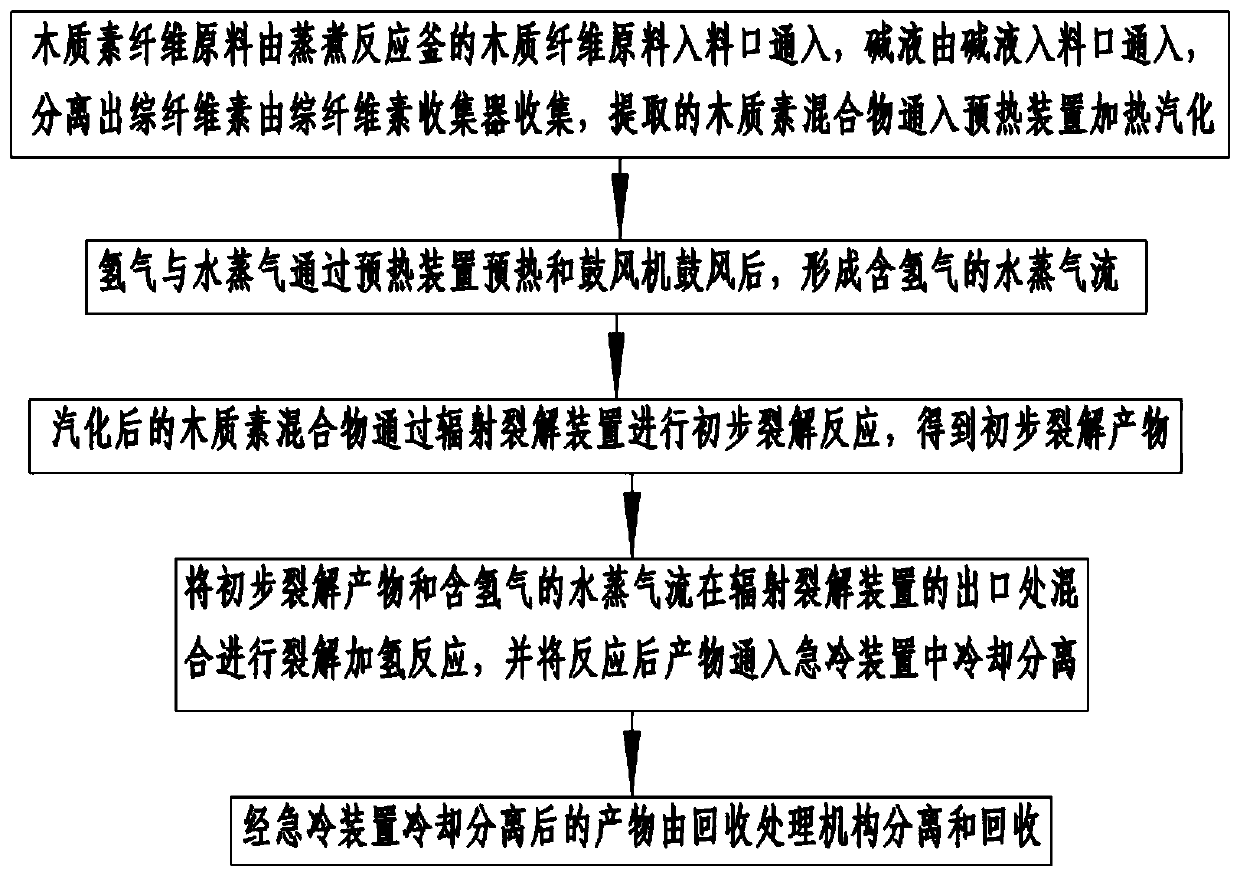

[0064] Embodiment 1: extract lignin and steam cracking in bamboo processing residue

[0065] Including the following steps:

[0066] (1) Grinding the bamboo processing residues to a particle size of less than 2 cm, adding 100 g of bamboo powder to 500 mL of an aqueous solution of sodium hydroxide (4%) and sodium sulfide (2%), heating to 180 ° C for 1 h, and naturally After cooling, vacuum filter to separate solid and liquid to obtain lignin-containing filtrate.

[0067] (2) After the filtrate that step (1) is obtained is preheated, enter the radiant section and carry out preliminary cracking reaction; Meanwhile, the water vapor stream that will contain 0.2% hydrogen is preheated, and at the outlet of the radiant section, the stream containing hydrogen Mix with the primary cracking product in the radiation section for further cracking and hydrogenation reaction;

[0068] (3) Inject the cracking reaction product finally obtained in step (2) into a quenching heat exchanger for ...

Embodiment 2

[0074] The difference between this embodiment and embodiment 1 is that in step (2) the steam stream containing 0.5% hydrogen is preheated.

Embodiment 3

[0076] The difference between this embodiment and embodiment 1 is only that 100g poplar wood powder is added to the above-mentioned aqueous solution in step (1).

[0077] The invention discloses a lignin separation and steam cracking system and its method, which have the following beneficial effects:

[0078] 1. Use lye to separate lignin from lignocellulosic raw materials, and use steam as an oxidant to crack lignin, then generate bio-oil and biogas through hydrogenation reaction, and enzymatic hydrolysis and saccharification of residues rich in cellulose and hemicellulose have high efficiency , and the equipment is simple, the working temperature of the whole system is low, the cracking process is stable, the process is simple and easy to implement, environmental protection and low toxicity, the recovery rate of lignin extraction is high, the efficiency of cellulose saccharification is high, and it is easy to realize industrialization;

[0079] 2. Preliminary separation and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com