Brewing method for restraining generation of ethyl carbamate in conventional yellow rice wine

A technology of urethane and rice wine, applied in the preparation of alcoholic beverages, etc., to achieve the effects of reducing accumulation, easy acquisition, and increasing ethanol content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

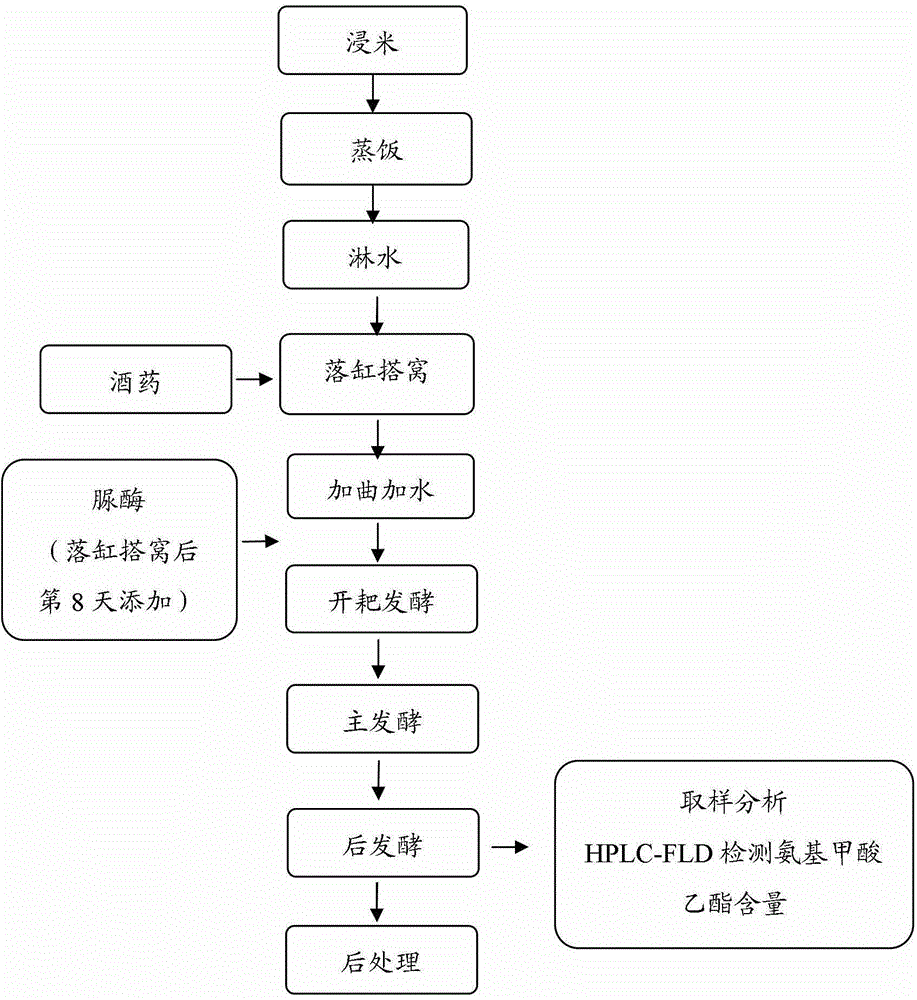

Method used

Image

Examples

Embodiment 1

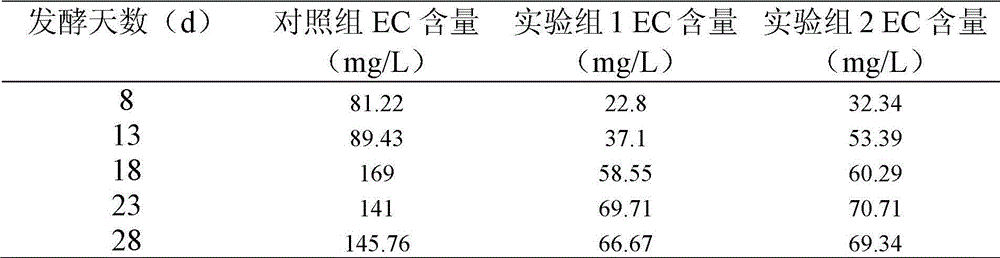

[0046] Control group: no urease is added during the brewing process;

[0047] Experimental group 1: Add urease on the 8th day after setting up the nest, the amount of urease added is 120U / 1kg rice;

[0048] Experimental group 2: Urease was added on the 8th day after setting up a nest in the tank, and the amount of urease added was 600 U / 1 kg of rice.

[0049] Sampling and analysis were performed every 2 days to determine the content of ethyl carbamate (EC) in the fermentation broth. The results are shown in Table 1. The results show that the content of urethane in the experimental group with urease as inhibitor is lower than that in the control group with natural fermentation, and the inhibitory effect is obvious; and the inhibitory effect of experimental group 1 is better than that of experimental group 2.

[0050] Table 1 The effect of urease on the ethyl carbamate content in yellow rice wine fermentation

[0051]

Embodiment 2

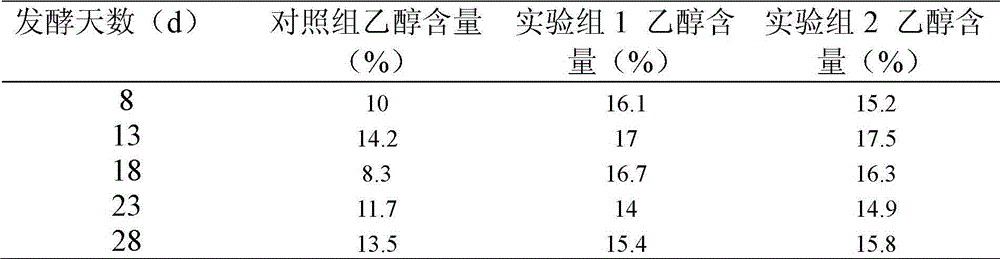

[0053] Control group: no urease is added during the brewing process;

[0054] Experimental group 1: Add urease on the 8th day after setting up the nest, the amount of urease added is 120U / 1kg rice;

[0055] Experimental group 2: Urease was added on the 8th day after setting up a nest in the tank, and the amount of urease added was 600U / 1kg rice.

[0056] Sampling and analysis were performed every 2 days to determine the ethanol content in the fermentation broth. The results are shown in Table 2. The results show that the ethanol content of the experimental group added with urease is higher than that of the control group, but the difference between experimental group 1 and experimental group 2 is not much, indicating that the addition of urease can increase the alcohol content in the fermentation process of rice wine, but the difference in the amount of urease added has an effect on the ethanol content Has little effect.

[0057] Table 2 The effect of urease on the ethanol content in ...

Embodiment 3

[0060] Control group: no urease is added during the brewing process;

[0061] Experimental group 1: Add urease on the 8th day after setting up the nest, the amount of urease added is 120U / 1kg rice;

[0062] Experimental group 2: Urease was added on the 8th day after setting up a nest in the tank, and the amount of urease added was 600U / 1kg rice.

[0063] Sampling and analysis were performed every 2 days to determine the urea content in the fermentation broth. The results are shown in Table 3. The results show that the experimental group added with urease has an inhibitory effect, and the urea content in the fermentation broth is much higher than that of the control group, which means that the urea content, the precursor of urethane used in the cell, is much lower than the control group. The concentration of urea in the fermentation broth of experimental group 1 is basically lower than that of experimental group 2, but the difference is not big. Because the inhibition of urethane is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com