Wine yeast capable of low-yielding hydrogen sulfide and ethyl carbamate as well as screening method and application of wine yeast

A technology of urethane and wine yeast, applied in the direction of microorganism-based methods, biochemical equipment and methods, wine preparation, etc., can solve the problems of loss of wine aroma substances, excessive copper ions in wine, and reduction of EC content in wine, etc. Achieve the effects of improving wine quality, optimizing wine production technology, and excellent winemaking characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0031] Implementation Case 1: Screening of Saccharomyces cerevisiae with low hydrogen sulfide and ethyl carbamate production

[0032] 1 method

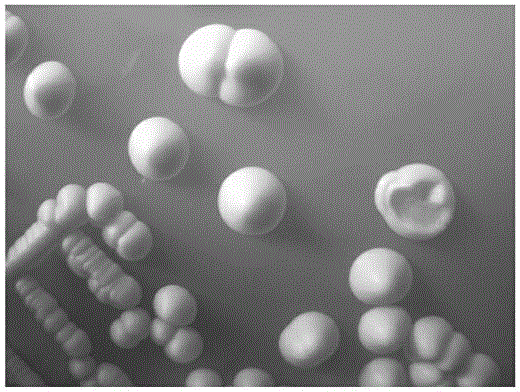

[0033] 1.1 Separation, purification, identification and preservation of yeast: Aseptically weigh about 100g of fresh and well-ripe grapes, put them into a sterile 500mL Erlenmeyer flask, crush them with a sterile hammer, and culture them at 27°C, every 24 At -72h, take 1 mL of fermentation broth, add 9 mL of sterile water for gradient dilution, take 50 μL of the diluted bacterial liquid and put it into WLN solid medium, spread it evenly with a sterile spatula, and incubate at 28 °C for 5 days. According to the characteristics of a single colony of Saccharomyces cerevisiae in WLN medium: the surface is smooth and creamy, with a conical protrusion in the center, surrounded by dark yellow or light green rings, opaque and creamy. Saccharomyces cerevisiae colonies on WLN medium in the test are shown in figure 1. Pick a single colony of...

Embodiment example 2

[0090] Implementation Case 2: Optimizing Low Yield H 2 Chardonnay Grape Juice Small Vessel Fermentation Test of S and EC Saccharomyces cerevisiae Strains

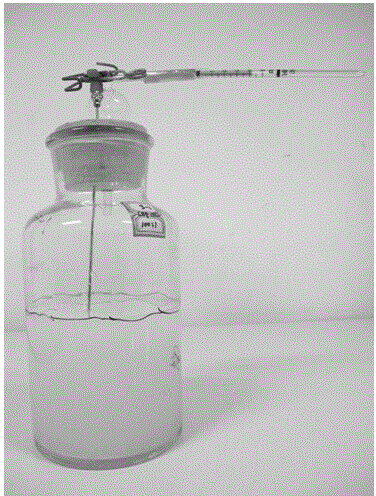

[0091] For detailed brewing process flow chart, see Figure 5. Fresh grapes of the white grape variety Chardonnay were pressed, by total SO 2 Add 6% sulfurous acid to reach the content of 50mg / L, the total sugar of grape juice is 210g / L, the total acid is 7.5g / L, the fermentation volume is 500mL, and each bottle is 5×10 5 cfu / mL (using a hemocytometer to count the strains cultured in the logarithmic phase to control the inoculum size) the inoculum amount was added to the grape juice activated yeast liquid, and the temperature was controlled at 18°C for fermentation. Due to the large amount of fermentation, the hydrogen sulfide detection tube device cannot be installed. Therefore, the detection of hydrogen sulfide in wine samples refers to GB / T 16489-1996 Determination of sulfide in water quality, methylene blue spectro...

Embodiment example 3

[0095] Implementation Case 3: Optimizing Low Yield H 2 Winery Fermentation Test of S and EC Saccharomyces cerevisiae Strains

[0096] The low-yielding H 2 The optimized strain CECLFN524 of S and EC was fermented in Ningxia Yuma Winery, Shanxi Rongzi and Gansu Mogao Winery for three consecutive years in 2010, 2011, and 2012 respectively (see the fermentation process flow chart Figure 5 , Image 6 ), to study its winemaking characteristics. Fresh wine grapes were destemmed and crushed, and sulfurous acid was added until the free sulfur content reached 45 mg / L. After 30 minutes, 20 mg / L pectinase was added. After mixing, the total acid and total sugar content of the grape juice were measured. Freshly adjusted sulfur grape juice was used to activate the strain, and the test strain was inserted into an appropriate amount of grape juice with a 3% inoculum. After cultivating in a constant temperature incubator at 28°C for 24 hours, the activated test strain was inoculated with 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com