Lactic acid bacteria not generating amino acid decarboxylase high-yield urease and application of lactic acid bacteria

An amino acid decarboxylase and lactic acid bacteria technology, applied in the field of lactic acid bacteria, can solve problems such as hidden dangers of fermented food safety, and achieve the effect of reducing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

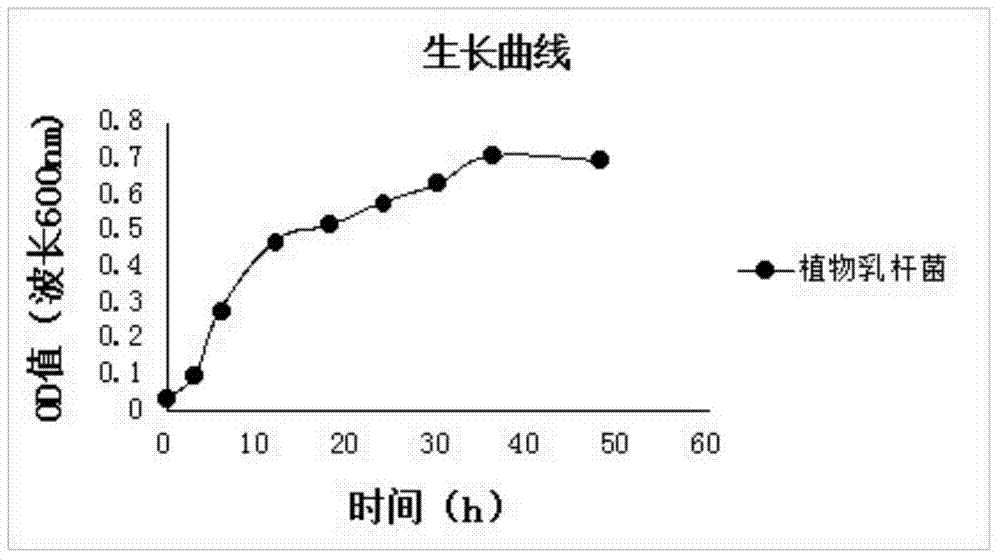

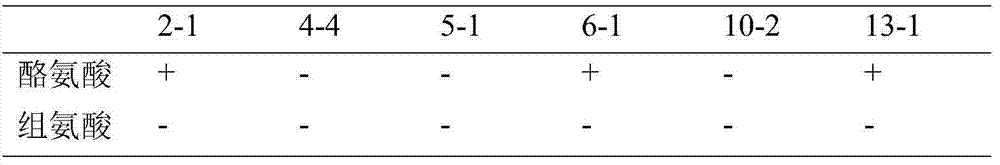

[0017] Example 1 Screening of lactic acid bacteria that do not produce amino acid decarboxylase and produce high urease

[0018] ① Take the homemade rice wine fermented mash on the 2nd day, 4th day, 5th day, 6th day, 10th day, and 13th day in the laboratory, respectively, and put them in blue-capped bottles;

[0019] ②Take the above 6 samples and dilute them by 10 4 、10 5 、10 6 After doubling, take 200 μL and spread it on the solid medium of the MRS plate, and culture it anaerobically at 37°C for 12 to 48 hours;

[0020] ③The next day, pick the single colony strains obtained on the plate and separate them by streaking, and culture them anaerobically at 37°C for 12 to 48 hours;

[0021] ④Repeat the above-mentioned streaking separation operation 3 times to obtain pure strains;

[0022] ⑤Finally, carry out microscopic examination on the strains obtained above in turn, exclude yeast, and obtain pure lactic acid bacteria;

[0023] 6. All the lactic acid bacteria obtained are i...

Embodiment 2

[0036] Example 2 Adding lactic acid bacteria to brew rice wine

[0037] The production process of the rice wine in the control group is as follows: steam the rice and pour it with cold water, then add raw wheat koji and purebred yeast to ferment it into rice wine. The pre-fermentation temperature is 30°C, and the time is 5-7 days; sky. The process of the present invention adopts the above-mentioned process, and the difference is that the screened Lactobacillus plantarum CCTCC M2015118 is added to the fermenter together with the raw materials rice, wheat koji, and distiller's yeast at the beginning stage, and the added amount of Lactobacillus plantarum is volume ratio 0.1‰~10‰ (the stated percentage per thousand is mL / L).

[0038] On the premise of not changing the rice wine process of the control group, lactic acid bacteria that do not produce amino acid decarboxylase and produce high urease were cultured at 37°C for 12 hours at the beginning to make a bacterial suspension, a...

Embodiment 3

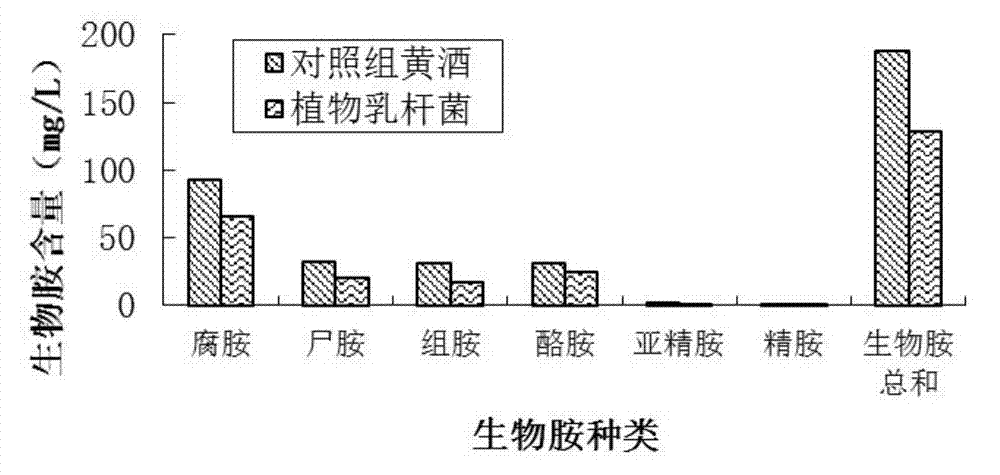

[0039] Example 3 The yellow rice wine obtained in Example 2 and the yellow rice wine of the control group were detected and analyzed

[0040] In this example, taking the rice wine of the control group as a reference sample, the biogenic amines and ethyl carbamate in the rice wine brewed with Lactobacillus plantarum added at a volume ratio of 10‰ were determined.

[0041] Accurately weigh 50 mg each of putrescine, cadaverine, histamine, tyramine, spermidine, and spermine, and prepare a standard stock with a concentration of 1 mg / mL (calculated as biogenic amine monomer) with 0.1 mol / L HCl solution Store in a refrigerator at 4°C; Accurately weigh an appropriate amount of dansyl chloride, prepare a stock solution with a concentration of 5 mg / mL with acetone, and store in a refrigerator at 4°C; draw each single-component standard stock solution of biogenic amines, and place in a 10mL volumetric flask In the method, use 0.1mol / L HCl solution to make the volume to the mark, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com