Digital printing transfer paper surface coating liquid

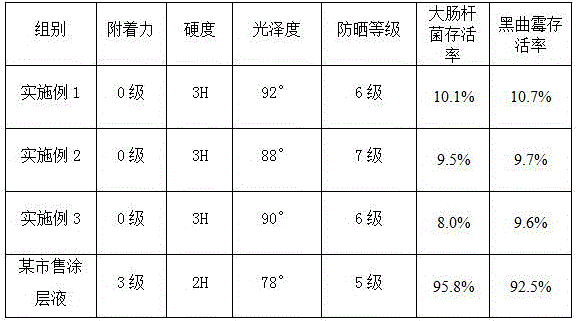

A technology of surface coating and digital printing, which is applied in coatings, anti-fouling/underwater coatings, polyurea/polyurethane coatings, etc., can solve the problems of single surface decoration, unsatisfactory decoration effect, and easy falling off of graphics and texts, and achieve High gloss, high sun protection level, good anti-mildew and antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The digital printing transfer paper surface coating solution in this embodiment is composed of the following components in parts by mass: 20 parts of methyl etherified urea-formaldehyde resin, 22 parts of methyltriacetoxysilane, 18 parts of polyvinyl chloride resin Parts, 16 parts of silicon dioxide powder, 22 parts of polyurethane, 18 parts of inorganic nano-zirconia, 16 parts of talcum powder, 22 parts of polymethyl methacrylate, 18 parts of dibutyl phthalate, 16 parts of chlorinated polypropylene resin Parts, 22 parts of isocyanate, 18 parts of polyvinyl alcohol, 18 parts of melamine formaldehyde resin, 16 parts of urethane resin, 22 parts of chlorothalonil, 18 parts of polytetrafluoroethylene powder, 16 parts of fluorescent powder, dichlorophenyl ether 22 parts of permethrin, 18 parts of sodium tripolyphosphate, 16 parts of phenothiazine, 22 parts of zircon powder, 18 parts of chloroplatinic acid, and 1000 parts of water.

[0017] The steps of the method for prepari...

Embodiment 2

[0022] The digital printing transfer paper surface coating solution in this embodiment is composed of the following components in parts by mass: 22 parts of methyl etherified urea-formaldehyde resin, 24 parts of methyltriacetoxysilane, 20 parts of polyvinyl chloride resin Parts, 18 parts of silicon dioxide powder, 24 parts of polyurethane, 20 parts of inorganic nano-zirconia, 18 parts of talcum powder, 24 parts of polymethyl methacrylate, 20 parts of dibutyl phthalate, 18 parts of chlorinated polypropylene resin 24 parts of isocyanate, 20 parts of polyvinyl alcohol, 20 parts of melamine formaldehyde resin, 18 parts of urethane resin, 24 parts of chlorothalonil, 20 parts of polytetrafluoroethylene powder, 18 parts of fluorescent powder, dichlorophenyl ether 24 parts of permethrin, 20 parts of sodium tripolyphosphate, 18 parts of phenothiazine, 24 parts of zircon powder, 20 parts of chloroplatinic acid, 1500 parts of water.

[0023] The steps of the method for preparing the abov...

Embodiment 3

[0028] The digital printing transfer paper surface coating solution in this embodiment is composed of the following components in parts by mass: 24 parts of methyl etherified urea-formaldehyde resin, 26 parts of methyltriacetoxysilane, 22 parts of polyvinyl chloride resin 20 parts, 20 parts of silicon dioxide powder, 26 parts of polyurethane, 22 parts of inorganic nano-zirconia, 20 parts of talcum powder, 26 parts of polymethyl methacrylate, 22 parts of dibutyl phthalate, 20 parts of chlorinated polypropylene resin 26 parts, 26 parts of isocyanate, 22 parts of polyvinyl alcohol, 22 parts of melamine formaldehyde resin, 20 parts of urethane resin, 26 parts of chlorothalonil, 22 parts of polytetrafluoroethylene powder, 20 parts of fluorescent powder, dichlorophenyl ether 26 parts of permethrin, 22 parts of sodium tripolyphosphate, 20 parts of phenothiazine, 26 parts of zircon powder, 22 parts of chloroplatinic acid, 2000 parts of water.

[0029] The steps of the method for prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com